Integrated pyrolysis device and pyrolysis method of household garbage and oil shale

A technology for domestic waste and oil shale, which is applied in the petroleum industry, processing hydrocarbon oil, special forms of dry distillation, etc., can solve the problems of consuming a lot of manpower, material resources and financial resources, and achieve good economic returns, high efficiency, and high pyrolysis efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

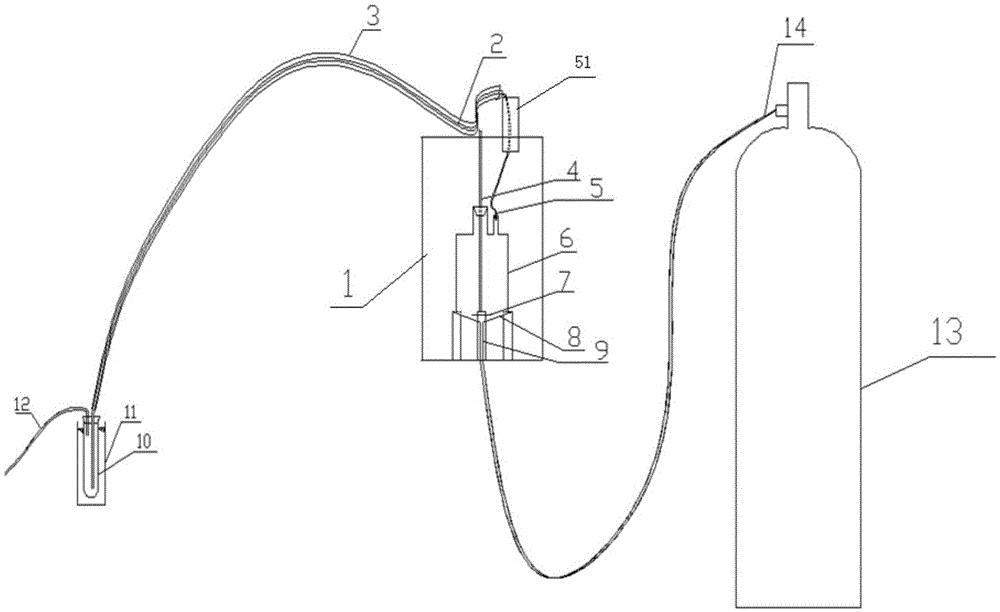

[0030] Such as figure 1 shown. The invention discloses an overall pyrolysis device for domestic garbage and oil shale, which includes a microwave generating device, and a material table 7 is arranged in the microwave generating cavity of the microwave generating device, and the material table 7 is used for placing materials to be pyrolyzed. The platform 7 is supported on the bottom of the generation cavity through the support frame 8;

[0031] The support frame 8 is provided with a part 9 for connecting with nitrogen gas; the support frame 8 has a movable cover body 6, which is used to cover the material to be pyrolyzed placed on the material table 7;

[0032] The top of the cover body 6 is provided with an insertion port for inserting a thermocouple 4 and an outlet pipe port 5 .

[0033] The top of the microwave generating device is provided with a gas collection device 51, and the outlet pipe port 5 is connected to the gas collection device 51 through a pipeline, and the g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com