Method and system for pyrolyzing and debrominating waste circuit boards

A technology for waste circuit boards and waste circuit boards, which is applied in chemical instruments and methods, solid waste removal, electronic waste recycling, etc. The effect of improving heat transfer efficiency and reducing treatment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

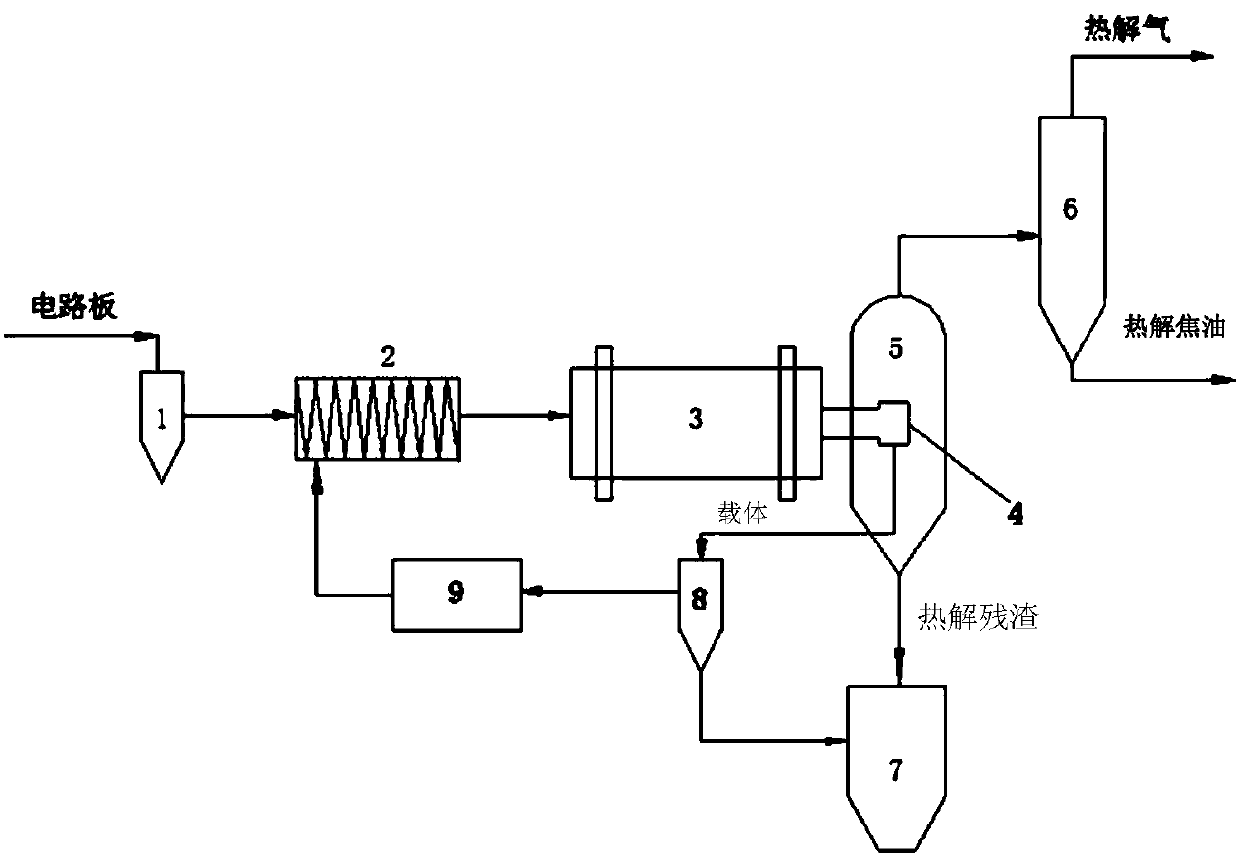

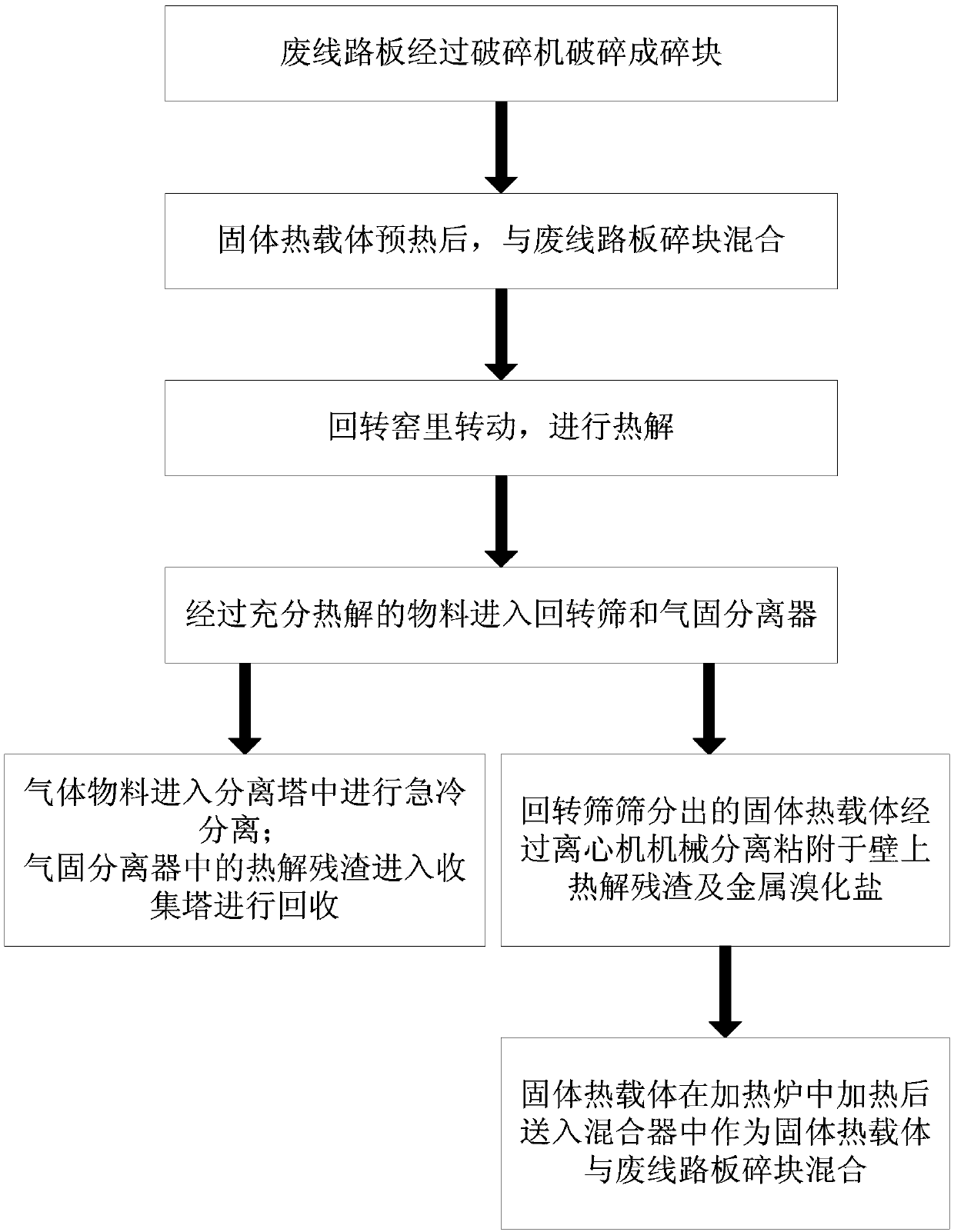

[0076] In this embodiment, waste printed circuit boards FR4 are used to carry out pyrolysis and debromination in the rotary kiln 3 pyrolysis process using the above system.

[0077] Such as figure 1 As shown, the collected waste circuit boards are pretreated and entered into the crusher 1 for crushing, so that the particle size is 5mm-10mm. The smaller the circuit board particle size, the more uniform the solid heat carrier and the circuit board are mixed, and the higher the pyrolysis efficiency is. high.

[0078] The broken circuit board and the solid heat carrier heated by the preheating device (such as the heating furnace 9) are quickly mixed evenly in the spiral mixer, and the solid heat carrier adopts iron oxide balls. The equivalent particle size of the iron oxide ball is larger than that of the circuit board to facilitate the separation from the pyrolysis coke in the later stage. The equivalent particle size of the iron oxide ball is 20mm. The heating furnace 9 uses e...

Embodiment 2

[0084] In this embodiment, waste printed circuit boards FR4 are used to carry out pyrolysis and debromination in the rotary kiln 3 pyrolysis process using the above system.

[0085] Such as figure 1 As shown, the collected waste circuit boards are pretreated and entered into the crusher 1 for crushing, so that the particle size is 10mm-15mm. The smaller the circuit board particle size, the more uniform the solid heat carrier and the circuit board are mixed, and the higher the pyrolysis efficiency is. high.

[0086] The broken circuit board and the solid heat carrier heated by the preheating device (such as the heating furnace 9) are quickly mixed evenly in the horizontal mixer, and the solid heat carrier adopts calcium oxide balls. The equivalent particle size of the calcium oxide ball is larger than that of the circuit board to facilitate the separation from the pyrolysis coke in the later stage. The equivalent particle size of the calcium oxide ball is 40mm. The heating fu...

Embodiment 3

[0092] In this embodiment, waste printed circuit boards FR4 are used to carry out pyrolysis and debromination in the rotary kiln 3 pyrolysis process using the above system.

[0093] Such as figure 1 As shown, the collected waste circuit boards are pretreated and entered into the crusher 1 for crushing, so that the particle size is 5-15mm. The smaller the circuit board particle size, the more uniform the solid heat carrier and the circuit board are mixed, and the higher the pyrolysis efficiency high.

[0094] The broken circuit board and the solid heat carrier heated by the preheating device (such as the heating furnace 9) are quickly mixed evenly in the V-shaped mixer, and the solid heat carrier adopts copper oxide balls. The equivalent particle size of the copper oxide ball is larger than that of the circuit board to facilitate the separation from the pyrolysis coke in the later stage. The equivalent particle size of the copper oxide ball is 30mm. The heating furnace 9 uses...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com