Efficient carcass pyrolysis treatment device and method

A processing device and meat carcass technology, which is used in indirect heating dry distillation, special form dry distillation, petroleum industry, etc., can solve the problems of less heat in the pyrolysis tank, long cooling time, coking and pyrolysis treatment of carcass, and shorten the processing cycle. , High energy utilization rate, improve the effect of pyrolysis effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

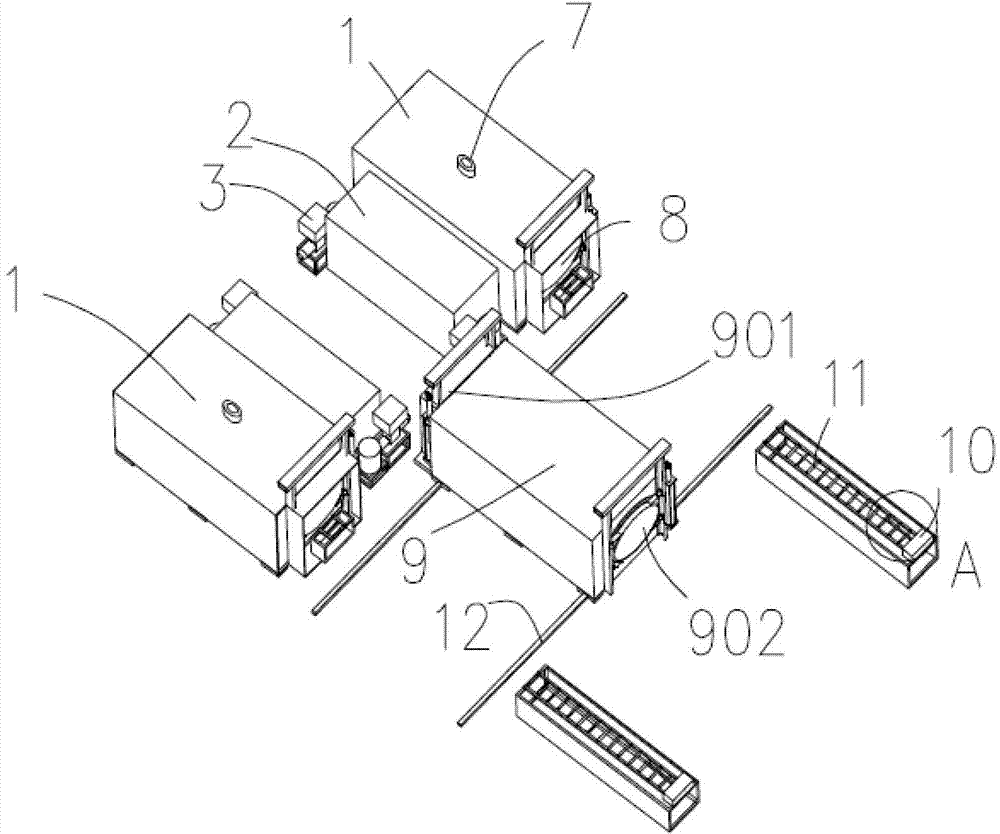

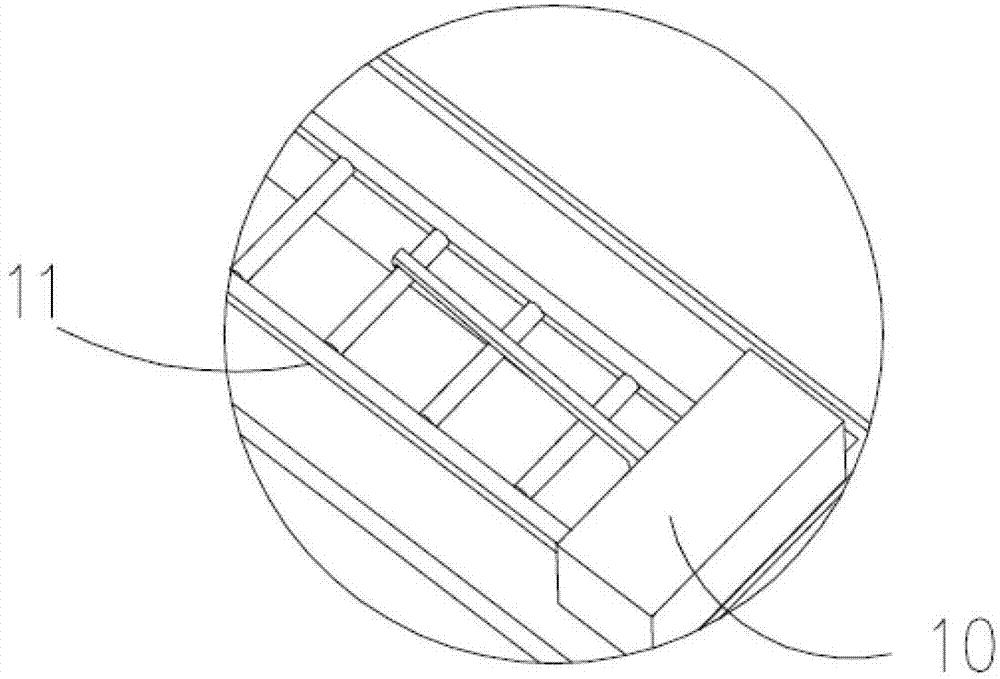

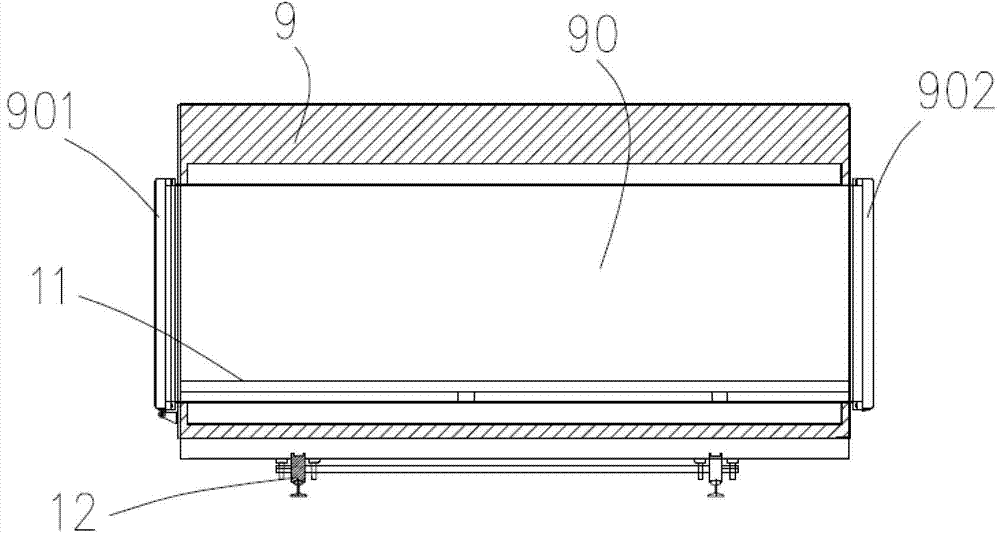

[0035] Such as figure 1 , figure 2 and image 3As shown, a high-efficiency meat carcasses pyrolysis treatment device includes a cooling chamber 9, two pyrolysis chambers 1, two combustion chambers 2, and four biomass burners 3. Each pyrolysis chamber 1 is equipped with a combustion chamber 2 and two biomass burners 3 . The pyrolysis chamber 1 is provided with a pyrolysis tank 6, and the pyrolysis tank 6 is provided with a material basket 60 for containing meat carcasses and a material basket guide rail 601 matched with the material basket 60, and the pyrolysis tank 6 is provided with an openable Or closed pyrolysis tank door 8, in addition, pyrolysis tank 6 is also provided with pyrolysis gas outlet pipe 61, and one end of pyrolysis gas outlet pipe 61 communicates with pyrolysis tank 6, and its other end is positioned at combustion chamber 2 ( Figure 5 shown). The cooling chamber 9 is provided with a cooling tank 90 adapted to the size and shape of the material basket 60...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com