Heat repairing method for organic contaminated soil

A technology of organic pollution and remediation method, applied in the field of thermal remediation of polluted soil, can solve the problems of difficulty in exhaust gas compliance, insufficient management, high treatment cost, etc., and achieve the effect of strong thermal decomposition and stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Before the thermal restoration, the soil in the organic polluted area was first tested, and the test results showed that the average depth of the polluted soil reached more than 2 meters, so the depth of the trench in this embodiment was 3 meters. For areas with less pollution, the depth of the trench can be between 1-2 meters.

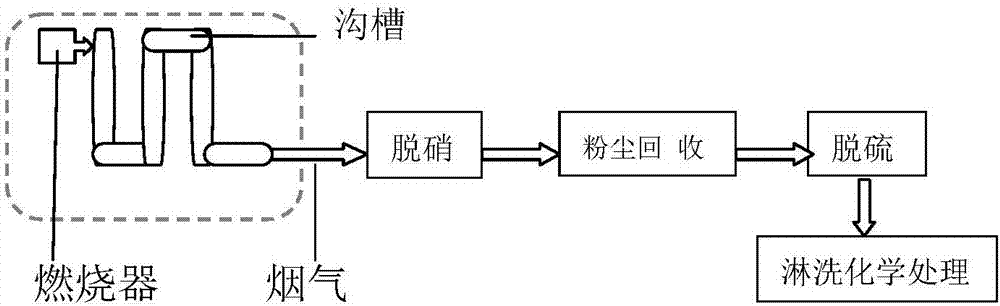

[0033] This example is the in-situ thermal restoration of organically polluted soil, the operation process is shown in figure 1 , including the steps:

[0034] (1) Dig a through trench in the area where the polluted site is located; the trench dug out in the polluted site has a depth of 3m, a width of 1m, and a length of 20m, and the other end of the trench is connected to the combustion furnace through the flue gas circulation pipeline 201 .

[0035] (2) Put the insulation cover on the groove, cover the upper part of the groove completely, and seal the gap of the cover with soil;

[0036] (3) One end of the trench is the flue gas inlet, whi...

Embodiment 2

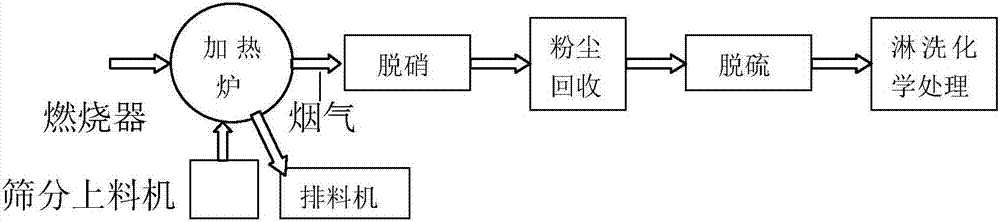

[0043] This example is an ex situ thermal remediation method for organically polluted soil. For the process, see figure 2 .

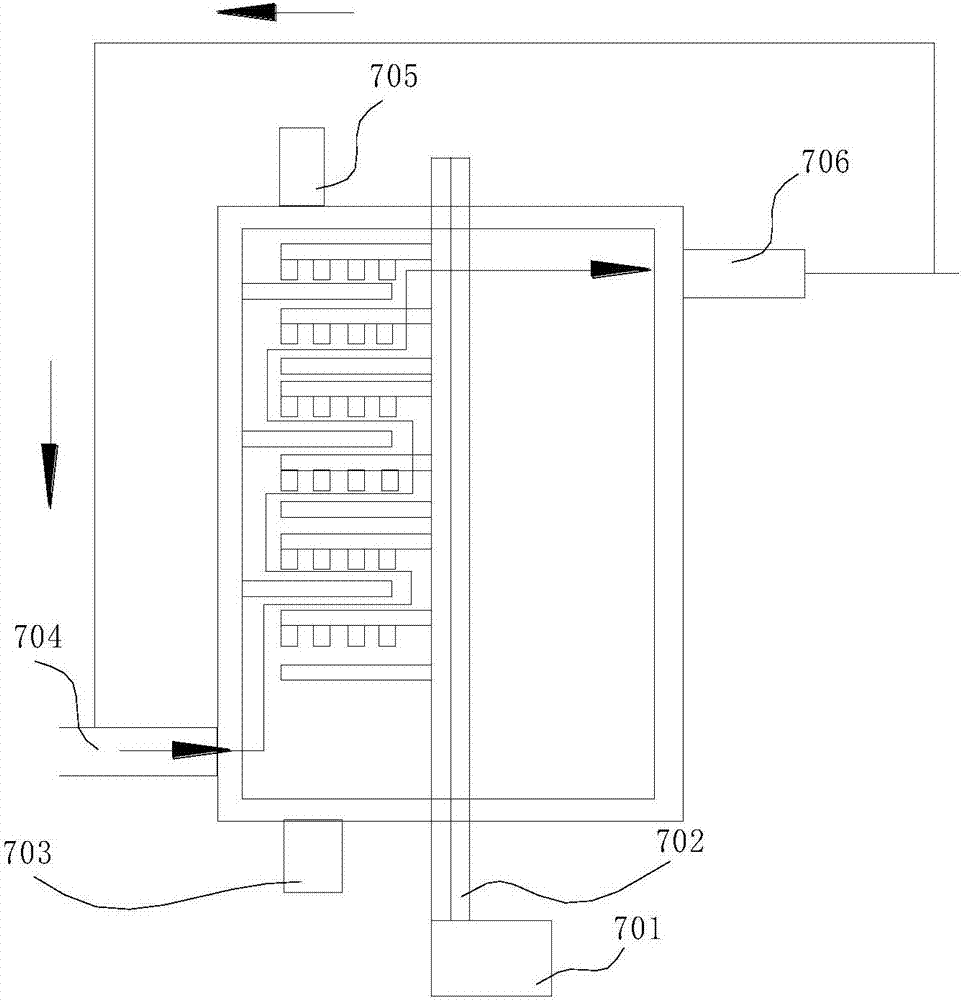

[0044] The operation steps are: excavate the organic polluted soil, send it to the screening feeder, and send the screened polluted soil into the heating furnace by the polluted soil inlet 705 on the top of the heating furnace (see image 3 ), the center of the heating furnace 7 is equipped with a rotating shaft 702, which is driven to rotate by the frequency conversion reducer 701; six layers of rake teeth are arranged on the rotating shaft 702, and the rake teeth correspond to the six layers of sieve plates for placing the soil; the sieve plates are singular in order and fixed There is a feeding channel between the furnace wall and the rotating shaft; the sieve plates are even-numbered in order, fixed on the rotating shaft, and there is a feeding channel between the furnace wall. The rotating shaft drives the rake teeth to unload the contaminated so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com