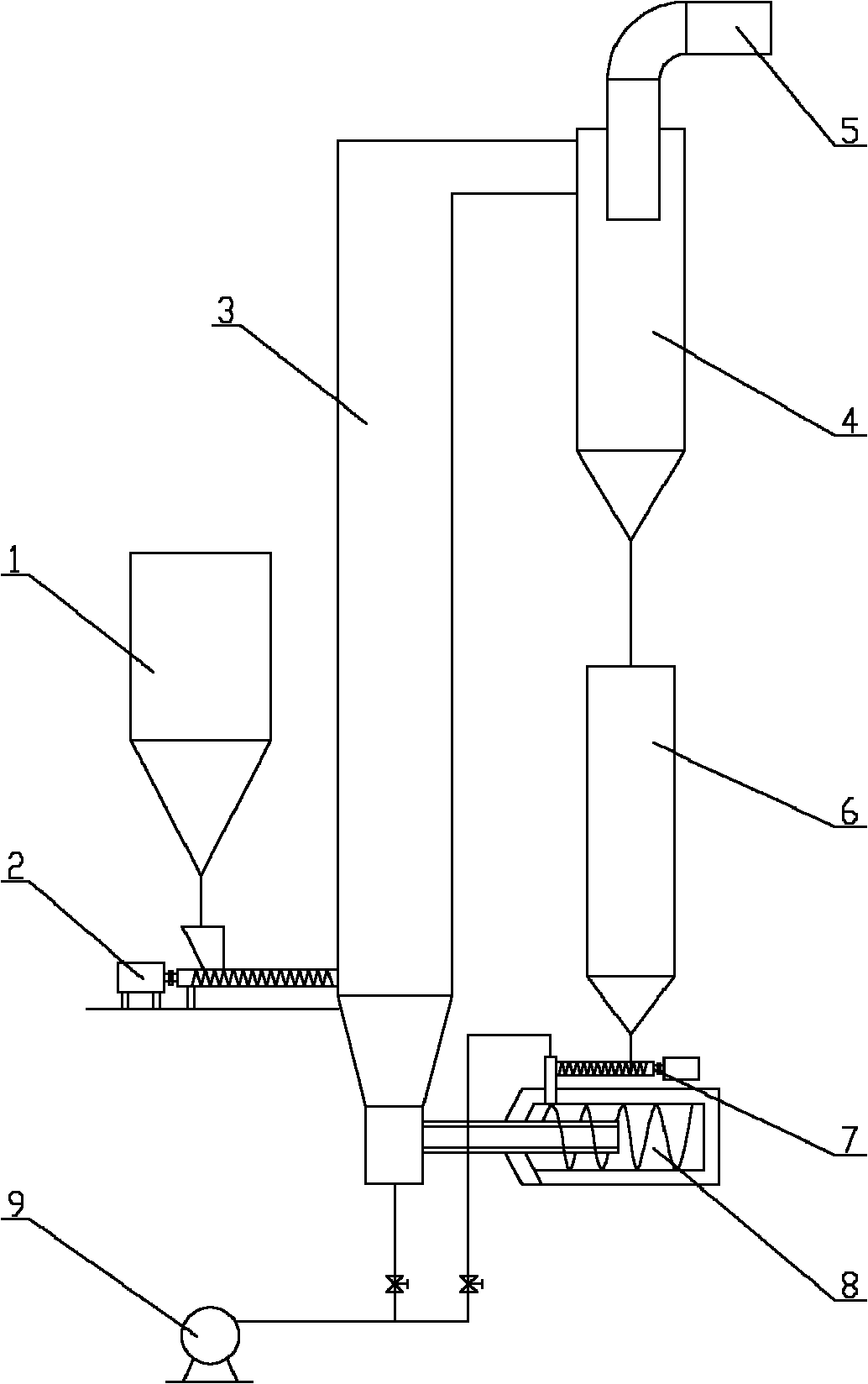

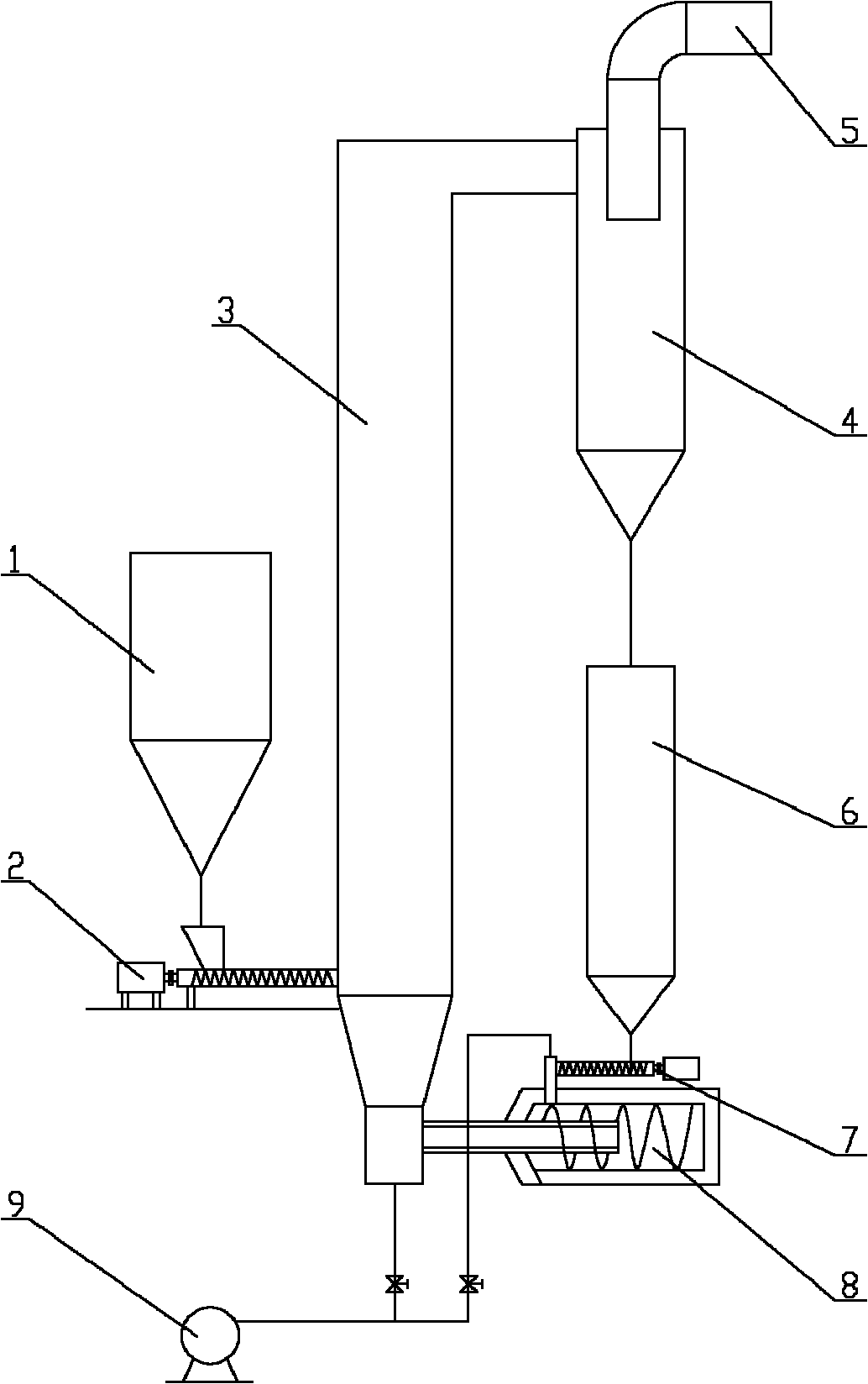

Two-section circulating fluidized bed biomass gasification system

A technology of circulating fluidized bed and fluidized bed gasifier, which is applied in the manufacture of combustible gas, petroleum industry, energy input, etc., can solve the problems of waste of resources and low thermal efficiency of gasifier, and achieves improved thermal efficiency and good pyrolysis. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The biomass gasification system consists of a silo 1, a first screw feeder 2, a fluidized bed gasifier 3, a cyclone ash removal device 4, an ash hopper 6, a cyclone burner 8, a second screw feeder 7, and a fan 9 composition. The lower part of the fluidized bed gasification furnace 3 is provided with two inlets, that is, the first inlet and the second inlet, and the first inlet is above the second inlet. The first inlet of the lower part of the fluidized bed gasification furnace 3 is connected to the first screw feeder 2, the upper end outlet of the fluidized bed gasification furnace 3 is connected to the cyclone ash removal device 4, and the upper end of the cyclone ash removal device 4 is connected to the gas pipe 5 , and the lower end is connected to the ash hopper 6, the outlet of the ash hopper 6 is connected to the second screw feeder 7, the outlet of the second screw feeder 7 is connected to the air inlet of the cyclone burner 8, and the outlet of the cyclone burn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com