Method for preparing MIBK through industrial by-product low-purity acetone

An industrial by-product and low-purity technology, which is applied in the field of MIBK preparation, can solve the problems of high catalyst use cost, deactivation, side reactions, etc., and achieve the effects of improving product selectivity, prolonging service life, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

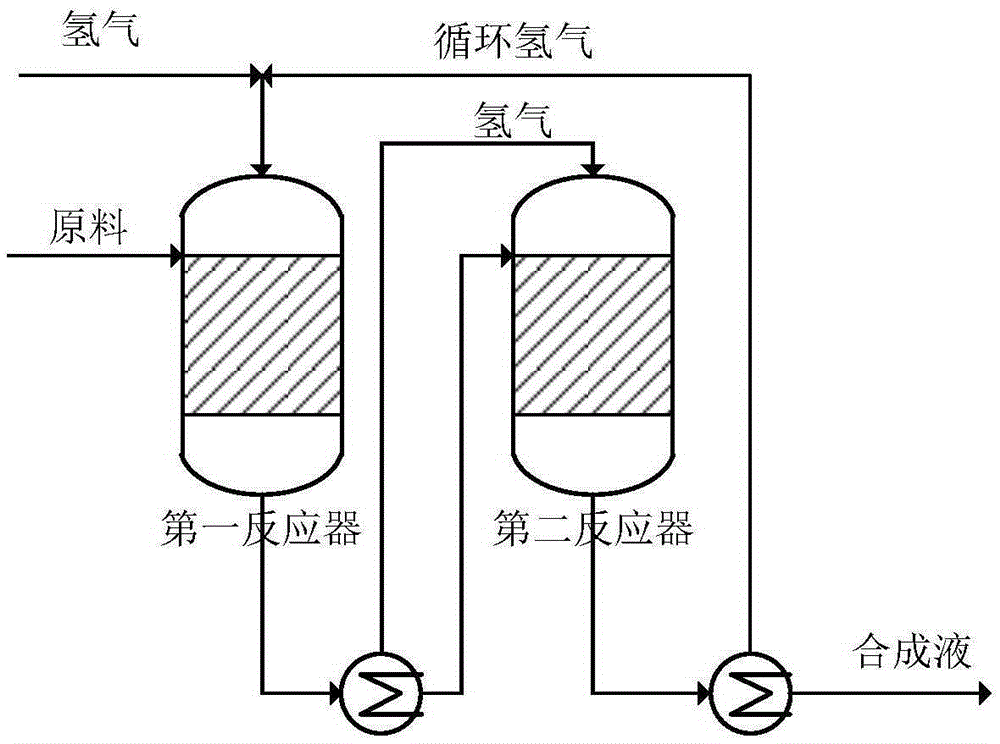

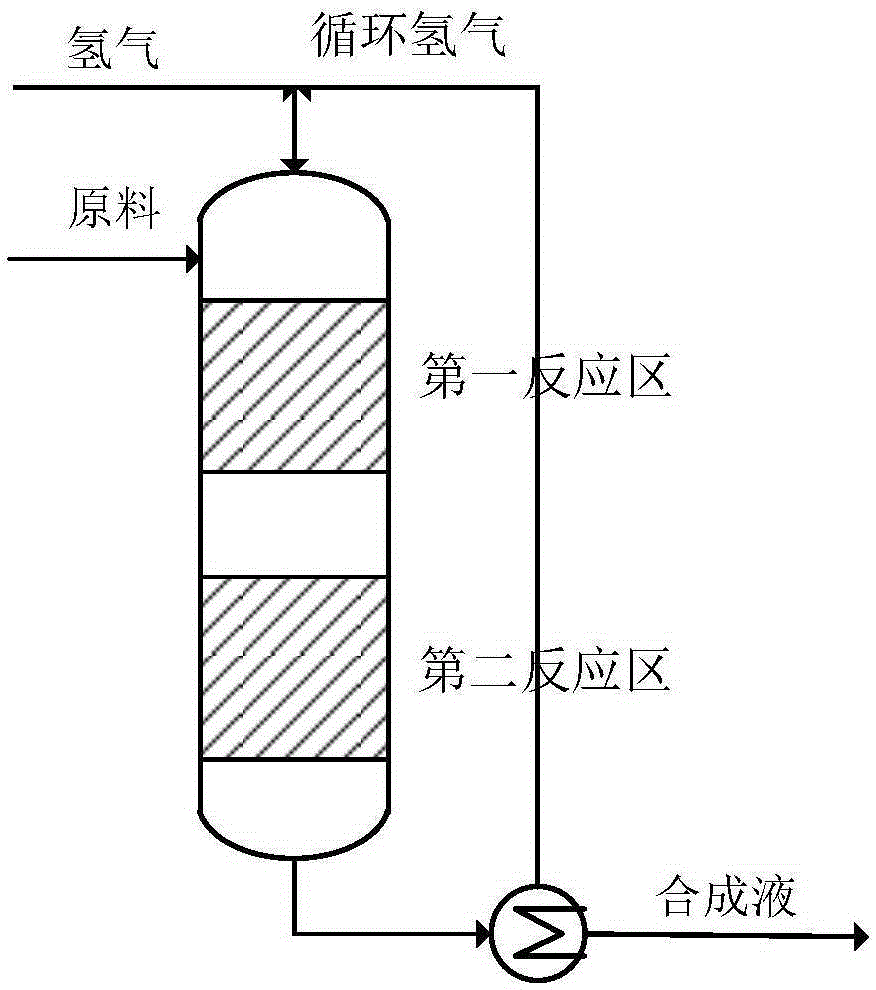

Method used

Image

Examples

Embodiment 1

[0049] The preparation of non-supported copper catalyst Cu-1, Cu-2 and Cu-3 in the protection catalyst used in the second stage process:

[0050] Cu(NO 3 ) 2 ·3H 2 O, Zn(NO 3 ) 2 ·6H 2 O, Al(NO 3 ) 3 9H 2 O, Ca(NO 3 ) 2 4H 2 O, Mg(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O was made into solution 1, solution 2 and solution 3 according to the ratio of 9:75:40:15:10:2, 35:55:25:8:15:1, 60:36:26:4:0.61:0.15 respectively , to which Na was slowly added dropwise 2 CO 3 Control the drop rate to keep the pH at 4-6. After the co-precipitation reaction is completed, age at room temperature for 12-24 hours; then vacuum filter to separate the precipitate from the mother liquor, and use a large amount of Rinse the precipitate with deionized water; dry the precipitate at 80-100°C for 8-12 hours, and then 2 Roast at 400°C for 4 hours in the atmosphere; then extrude, and spray the molded catalyst with an ethanol-water solution containing 1% commercial KP-853 water repellent on th...

Embodiment 2

[0053] Preparation of supported copper catalyst Cu-Sn-1, Cu-Sn-2 and Cu-Sn-3 in the protection catalyst used in the second stage process:

[0054] CuCl 2 2H 2 O and SnCl 4 ·5H 2 O was added to the molten stearic acid according to a certain mass ratio, and stirred magnetically at 80-100°C for 6-8 hours. After the dehydration was complete, a certain amount of butyl titanate was added and stirred vigorously for 3-5 hours, and the shell formed a translucent sol. , Dry at 100°C for 4-6 hours, then bake in a muffle furnace at 400°C-500°C for 2-4 hours, and then reduce it under a hydrogen atmosphere at 350-400°C for 4-6 hours.

[0055] According to the above method, m(Cu):m(Sn):m(TiO 2 ) is the catalyst Cu-Sn-1 of 9:11:80, and m(Cu):m(Sn):m(TiO 2 ) is the catalyst Cu-Sn-2 of 25:5:70, and m(Cu):m(Sn):m(TiO 2) is the catalyst Cu-Sn-3 of 39:16:45.

Embodiment 3

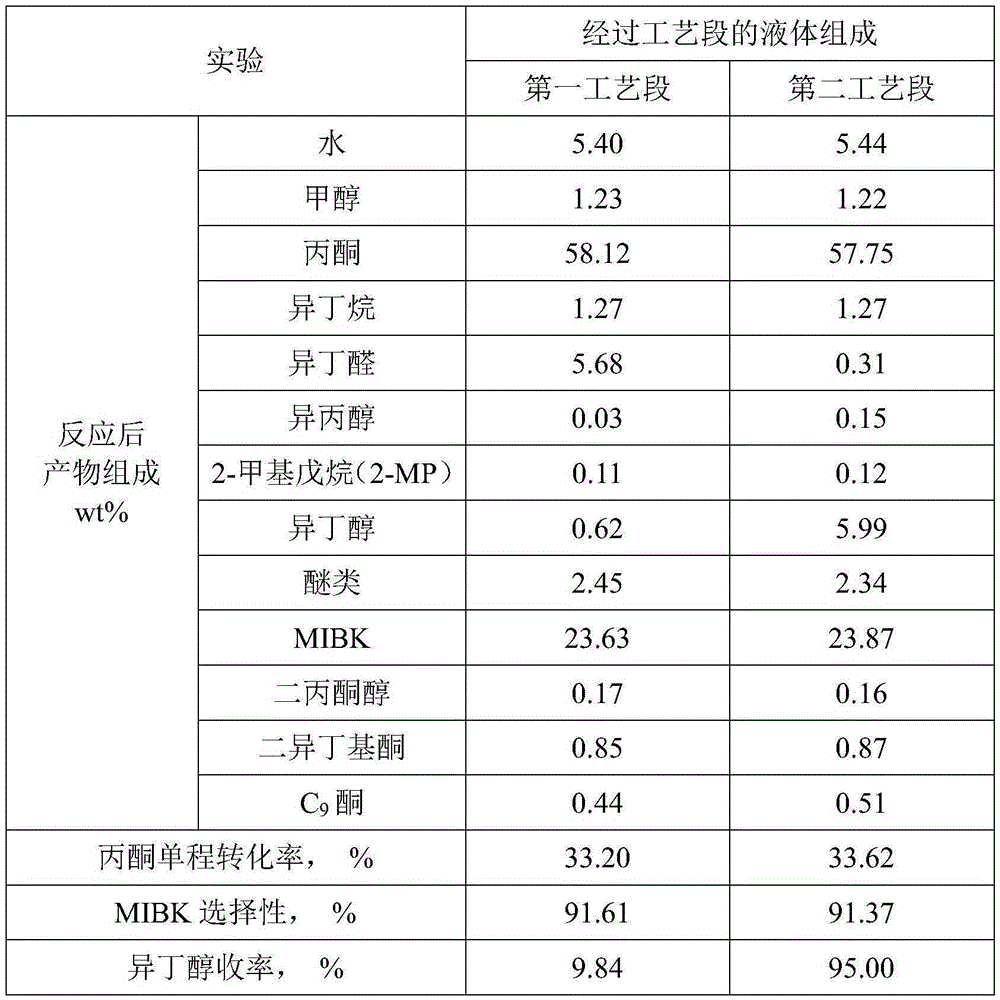

[0057] The raw material composition is as shown in Table 1, the catalyst of the first process section is Amberlyst CH-28, the reactor is a fixed-bed reactor, the reaction temperature is 100°C, the reaction pressure is 3MPa, the hydrogen-to-oil ratio (molar ratio) is 0.7, and the air speed is 1h -1 . The catalyst in the second process stage is Ruike D5H5A, the reactor is a continuous stirred tank reactor, the reaction temperature is 125°C, the reaction pressure is 3MPa, the volume of the reactor is 2L, the catalyst dosage is 5g, and the residence time is 30min.

[0058] The reaction products of the first stage process and the second stage process were collected for chromatographic analysis, and the specific results are listed in Table 2.

[0059] The reaction result after the two-stage process of table 2

[0060]

[0061] As can be seen from Table 2: when there is only one stage of technology, the yield of isobutanol is only 9.84%, and most of the isobutane epoxy is conver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com