Method for preparing high-strength boron carbide porous ceramics

A technology of porous ceramics and boron carbide, applied in the field of ceramic molding, can solve the problems of uneven pore distribution, complex preparation method, and many closed pores, etc., and achieves the effect of high boron carbide content, simple control method, and reduction of the number of pores.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

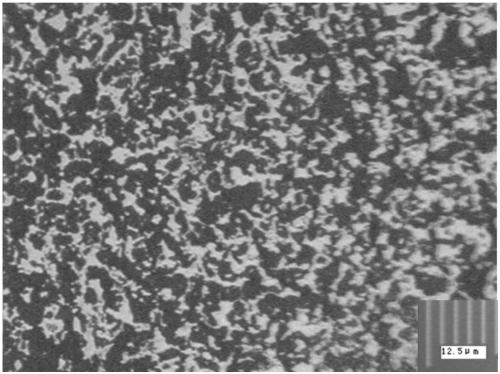

[0034] Embodiment 1, a kind of preparation method of high strength boron carbide porous ceramics, its preparation method is as follows:

[0035] 1) Mixing: Weigh 180g of boron carbide with a particle size of 300μm and 20g of boron carbide with a particle size of 10μm, add 12g of water-soluble phenolic resin as a binder and sintering aid, and add 6g of carboxymethyl cellulose to form a 40% The aqueous solution of solid content is used as suspending agent, and 20g glycerol is used as lubricant.

[0036] 2) Ball milling: After pouring the raw materials into the ball milling tank, add 240°C of water, and then enter the stirring mill for 8 hours to make it fully mixed to obtain ceramic slurry;

[0037] 3) Spray granulation: spray granulate the slurry and control the outlet temperature to 100° C. to obtain powder. Pass the ceramic powder through a 60-mesh standard sieve, and then properly dry it to control its water content to 0.5%.

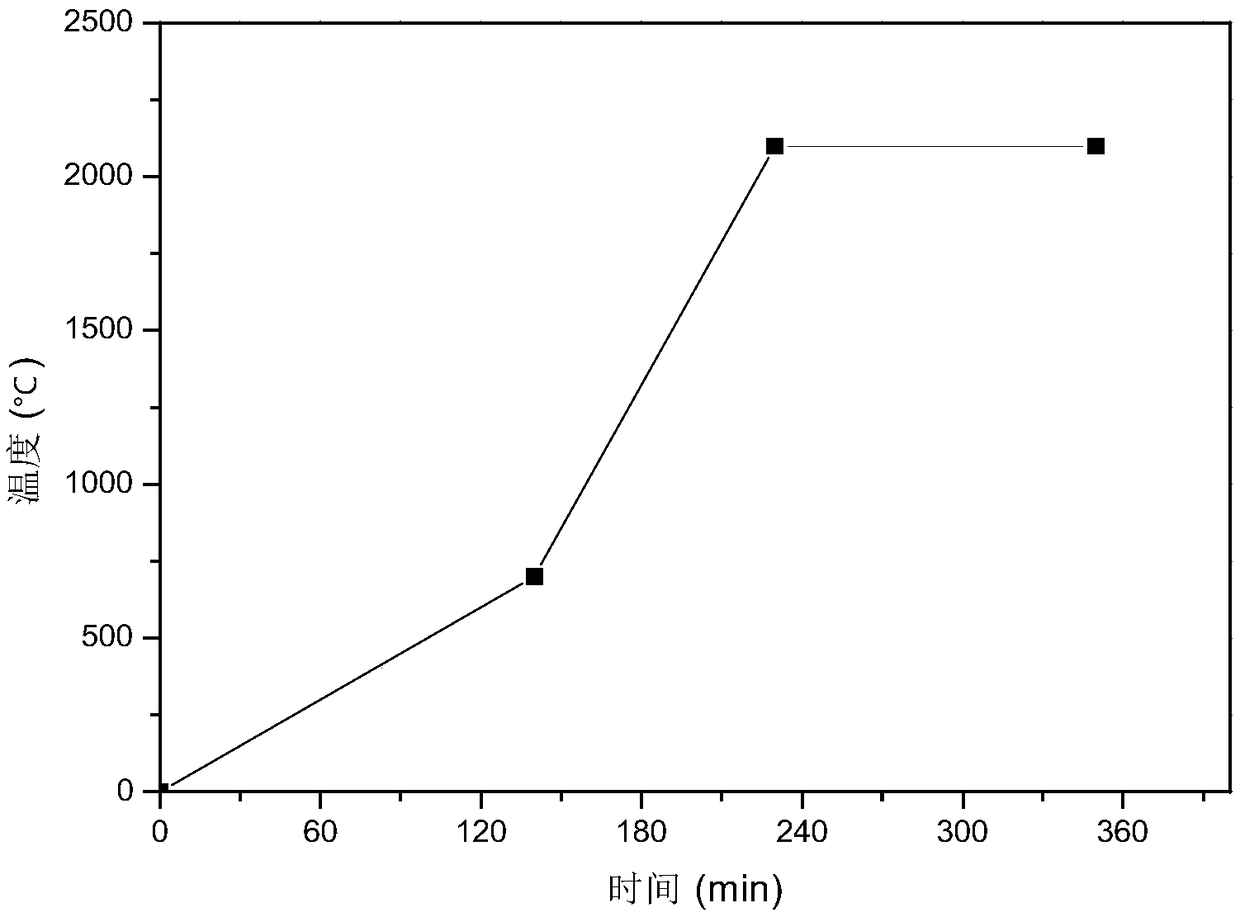

[0038] 4) Dry pressing molding: the obtained p...

Embodiment 2

[0041] Embodiment 2, a kind of preparation method of high strength boron carbide porous ceramics, its preparation method is as follows:

[0042] 1) Mixing: Weigh 100g of boron carbide with particle size of 100μm and 100g of boron carbide with particle size of 5μm, add 16g of PVB as binder, 12g of silicon carbide sintering aid, add 1.5g of sodium citrate pentahydrate suspending agent, 10g of glycerin as lubricant.

[0043] 2) Ball milling: pour the raw materials into a ball milling tank, add 350 g of water, and then stir and mill for 24 hours to fully mix to obtain a ceramic slurry;

[0044] 3) Spray granulation: spray granulate the slurry and control the outlet temperature to 100° C. to obtain powder. Pass the ceramic powder through an 80-mesh standard sieve, and then properly dry it to control its moisture content to 1.5%.

[0045] 4) Dry pressing molding: the obtained powder is passed through a dry pressing molding equipment to prepare a boron carbide ceramic green body, t...

Embodiment 3

[0048] Embodiment 3, a kind of preparation method of high strength boron carbide porous ceramics, its preparation method is as follows:

[0049] 1) Mixing: Weigh 120g of boron carbide with a particle size of 30μm and 80g of boron carbide with a particle size of 2μm, add 10g of PVA as a binder, 16g of carbon black as a sintering aid, and 15g of glycerin as a lubricant.

[0050] 2) Ball milling: After pouring the raw materials into the ball milling tank, add 400 g of water (the weight ratio of raw materials to water is 100:120), and then carry out planetary ball milling, and the ball milling time is 2 hours, so that they are fully mixed to obtain ceramic slurry;

[0051] 3) Spray granulation: spray granulate the slurry and control the outlet temperature to 100° C. to obtain powder. Pass the ceramic powder through a 120-mesh standard sieve, and then properly dry it to control its moisture content to 3%.

[0052] 4) Dry pressing molding: the obtained powder is passed through a dr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

| Apparent density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com