Preparation method of SiGe alloy thermoelectric material

A technology of thermoelectric materials and alloys, applied in the field of preparation of SiGe alloy thermoelectric materials, can solve the problems of low mutual diffusion speed, volatilization of doping elements, easy volatilization, etc., and achieves easy control of process parameters, excellent thermoelectric performance, and simple preparation method. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

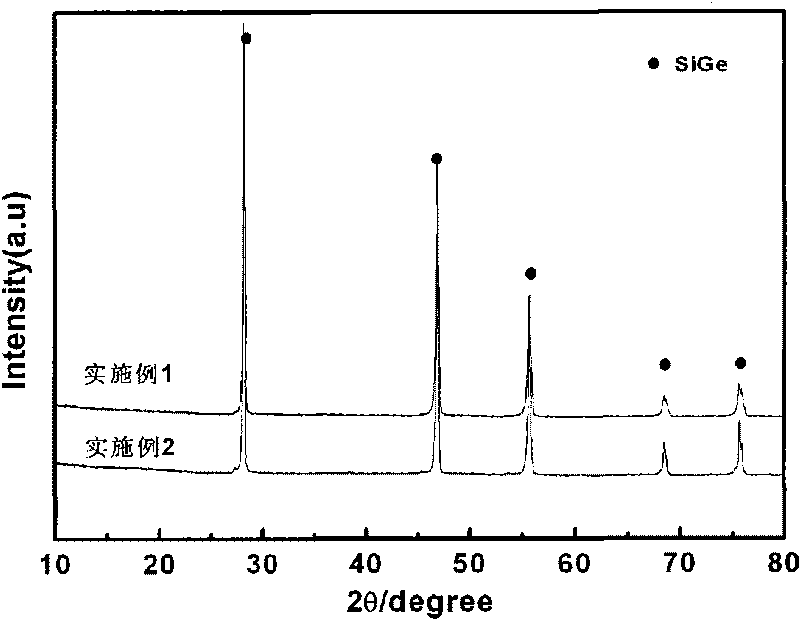

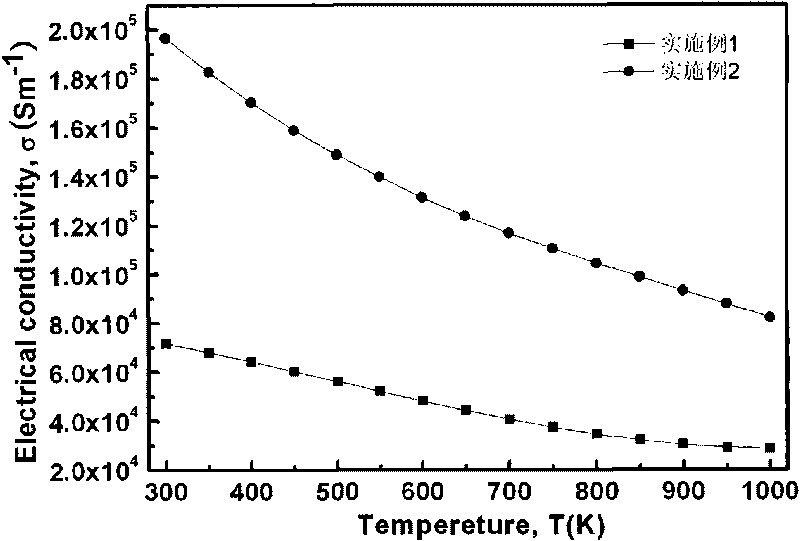

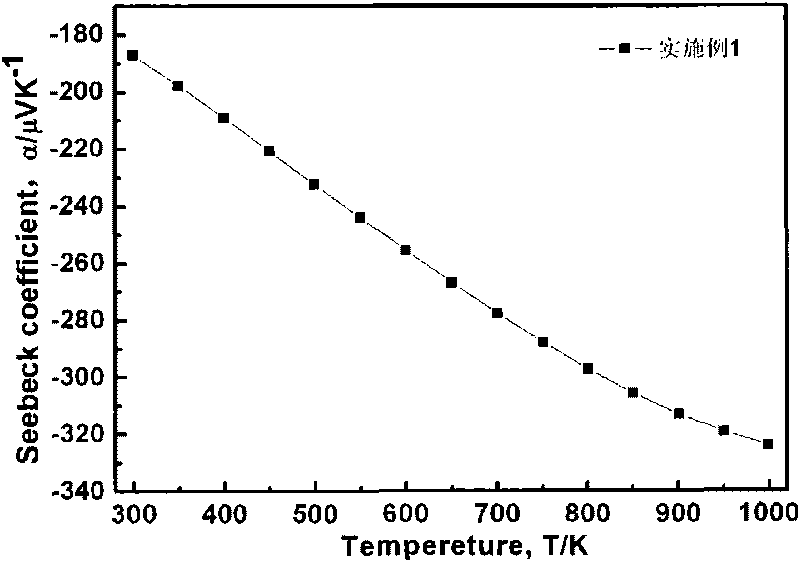

[0025] A kind of SiGe alloy thermoelectric material (N-type Si 80 Ge 20 P 2 The preparation method of thermoelectric material), it comprises the steps:

[0026] 1) According to the chemical formula Si 80 Ge 20 P 2 Take by weighing Si block, Ge block and P powder raw material altogether 5g, wherein the purity of Si block is 99.99% (mass), the purity of Ge block is 99.99% (mass), the purity of P powder is 99.99% (mass), Si Ingots, Ge ingots and P powder raw materials are mixed and put into an argon arc melting furnace for melting twice, each time for 30s, and cooled naturally to obtain alloy ingots.

[0027] 2) Grinding the obtained alloy block with sandpaper to remove surface dirt and impurities, then ultrasonically cleaning it with ethanol, and after drying, crush the alloy block into particles in a mortar; put the crushed alloy particles into a stainless steel ball mill jar , add 200g of stainless steel balls and 10mL of alcohol, the speed of the ball mill is 400rpm, an...

Embodiment 2

[0031] A kind of SiGe alloy thermoelectric material (P-type Si 80 Ge 20 B 2 The preparation method of thermoelectric material), it comprises the steps:

[0032] 1) According to the chemical formula Si 80 Ge 20 B 2 Take by weighing Si block, Ge block and B powder raw material altogether 5g, wherein the purity of Si block is 99.99% (mass), the purity of Ge block is 99.99% (mass), the purity of B powder is 99.99% (mass), Si Ingots, Ge ingots and B powder are mixed and put into an argon arc melting furnace to melt for 3 times, 30s each time, and cool naturally to obtain alloy ingots.

[0033] 2) Grinding the obtained alloy block with sandpaper to remove surface dirt and impurities, then ultrasonically cleaning it with ethanol, and after drying, crush the alloy block into particles in a mortar; put the crushed alloy particles into a stainless steel ball mill jar , add 200g of stainless steel balls and 10mL of alcohol, the speed of the ball mill is 400rpm, and ball mill for 2h...

Embodiment 3

[0037] A kind of SiGe alloy thermoelectric material (P-type Si 80 Ge 20 al 3 The preparation method of thermoelectric material), it comprises the steps:

[0038] 1) According to the chemical formula Si 80 Ge 20 al 3 Take by weighing Si block, Ge block and Al powder raw material altogether 5g, wherein the purity of Si block is 99.99% (mass), the purity of Ge block is 99.99% (mass), the purity of Al powder is 99.99% (mass), Si Ingots, Ge ingots and Al powder were mixed and put into an argon arc melting furnace to melt for 3 times, 30s each time, and cooled naturally to obtain alloy ingots.

[0039] 2) Grinding the obtained alloy block with sandpaper to remove surface dirt and impurities, then ultrasonically cleaning it with ethanol, and after drying, crush the alloy block into particles in a mortar; put the crushed alloy particles into a stainless steel ball mill jar , add 200g of stainless steel balls and 10mL of alcohol, the speed of the ball mill is 200rpm, and ball mil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com