Method for surface boriding of hard alloy

A technology of hard alloy and treatment method, which is applied in the direction of metal material coating process, coating, solid-state diffusion coating, etc., and can solve problems such as difficult boronizing treatment of blanks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

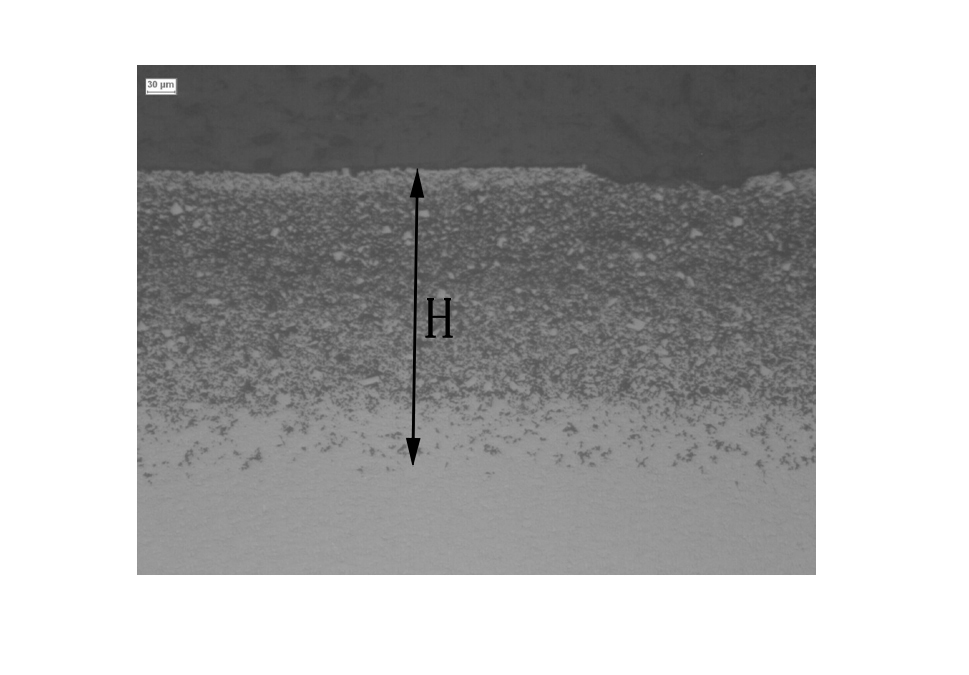

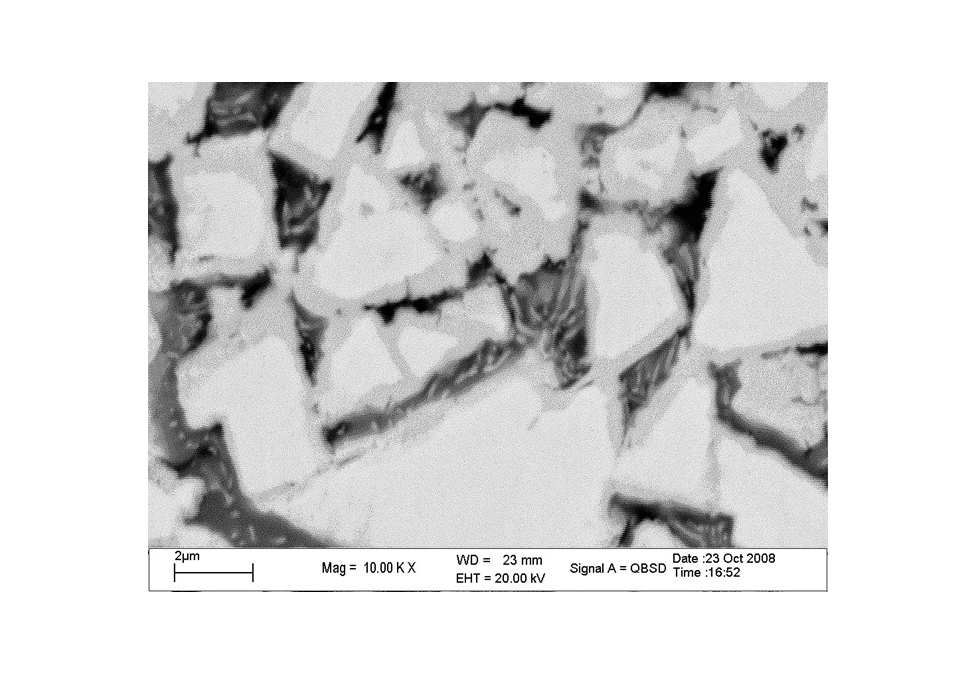

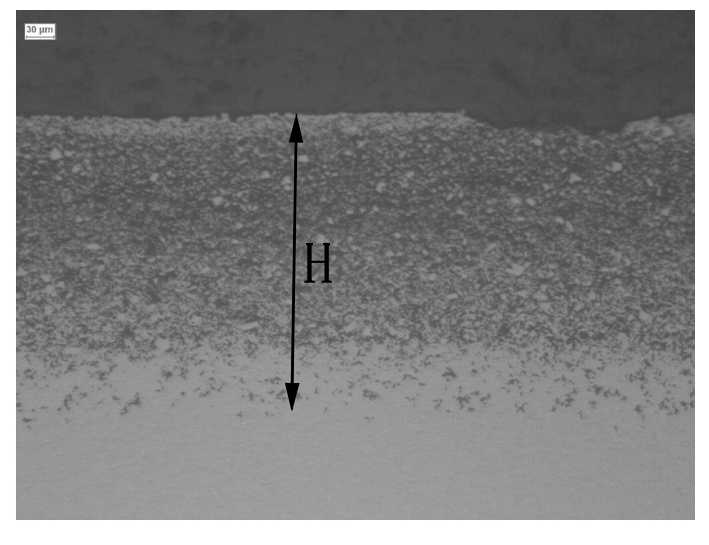

Image

Examples

Embodiment 1

[0023] For long carbide samples (5.25×6.5×20mm, the following samples have the same shape and size) with Co weight percentages of 6%, 11%, and 15% to be boronized, use a silicon nitride grinding wheel to remove the surface oxide layer; Solid boronizing agent, the weight percentage of each component is: 39%B 4 C. 10%KBF 4 , 7% rare earth oxide, 1% Mg powder, 5% ammonium carbonate, 24% graphite particles, 14% SiC.

[0024]Embed the above-mentioned cemented carbide to be boronized in the boronizing agent, and at the same time embed the wear-resistant sample (32×18×7mm, the same shape and size of the following wear-resistant samples) in the boronizing agent, and place it in the threaded sealing cover In the graphite jar, screw the lid tightly and put it into the induction heating furnace. Close the lid of the induction furnace and vacuumize. When the vacuum reaches 100Pa or more, turn off the vacuum unit, feed nitrogen to 0.07MPa, and start heating. The boronizing temperature ...

Embodiment 2

[0027] Use diamond grinding wheel to grind the hard alloy strip sample to be boronized with 6% and 11% by weight of Co to remove the surface oxide layer; prepare a solid boronizing agent, and the weight percentage of each component is: 13%BN, 20% %B 4 C, 1% amorphous boron, 7% NH 4 BF 4 , 3% rare earth oxide, 1% Mg powder, 34% graphite particles, 21% Al 2 o 3 pink.

[0028] The above-mentioned cemented carbide and wear-resistant samples to be boronized are buried in the boronizing agent, placed in a graphite tank with a threaded sealing cover, tightened the cover, and placed in an induction heating furnace. Close the furnace cover of the induction furnace and vacuumize it. When the vacuum reaches 100Pa or more, close the vacuum unit and feed the flowing H 2 Gas, keep the gas pressure in the furnace positive, and start heating. The boronizing temperature is 900°C and the temperature is kept for 5 hours. At boronizing temperature, the NH in the activator 4 BF 4 The gas...

Embodiment 3

[0031] For the cemented carbide button sample to be boronized with a Co weight percentage of 15%, use sandblasting to remove the surface oxide layer; prepare a solid boronizing agent, and the weight percentage of each component is: 5%B 4 C. 7%KBF 4 , 3% rare earth oxide, 10% graphite particles, 75% SiC.

[0032] The above-mentioned cemented carbide and wear-resistant samples to be boronized are buried in the boronizing agent, placed in a graphite tank with a threaded sealing cover, tightened the cover, and placed in an induction heating furnace. Close the induction furnace cover and vacuumize. When the vacuum reaches 100Pa or more, turn off the vacuum unit, feed Ar gas to 0.07MPa, and start heating. The boronizing temperature is 1000°C and the temperature is kept for 5 hours. At boronizing temperature, KBF in activator 4 The gas produced by decomposition, and part of the solid boron donor B 4 C reacts to form B atoms, carried by the aforementioned unreacted decomposition ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com