Application of modified polyurethane sponge in repair of non-aqueous organic-phase liquid contaminated soil and repair method of non-aqueous organic-phase liquid contaminated soil

A polyurethane sponge and repair method technology, which is applied in the application field of modified polyurethane sponge in repairing non-aqueous organic phase liquid contaminated soil, can solve the problems of high operation and maintenance costs, VOCs escape, complex VOCs treatment equipment, etc., and achieve large-scale Large-scale production, significant adsorption effect, and convenient method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

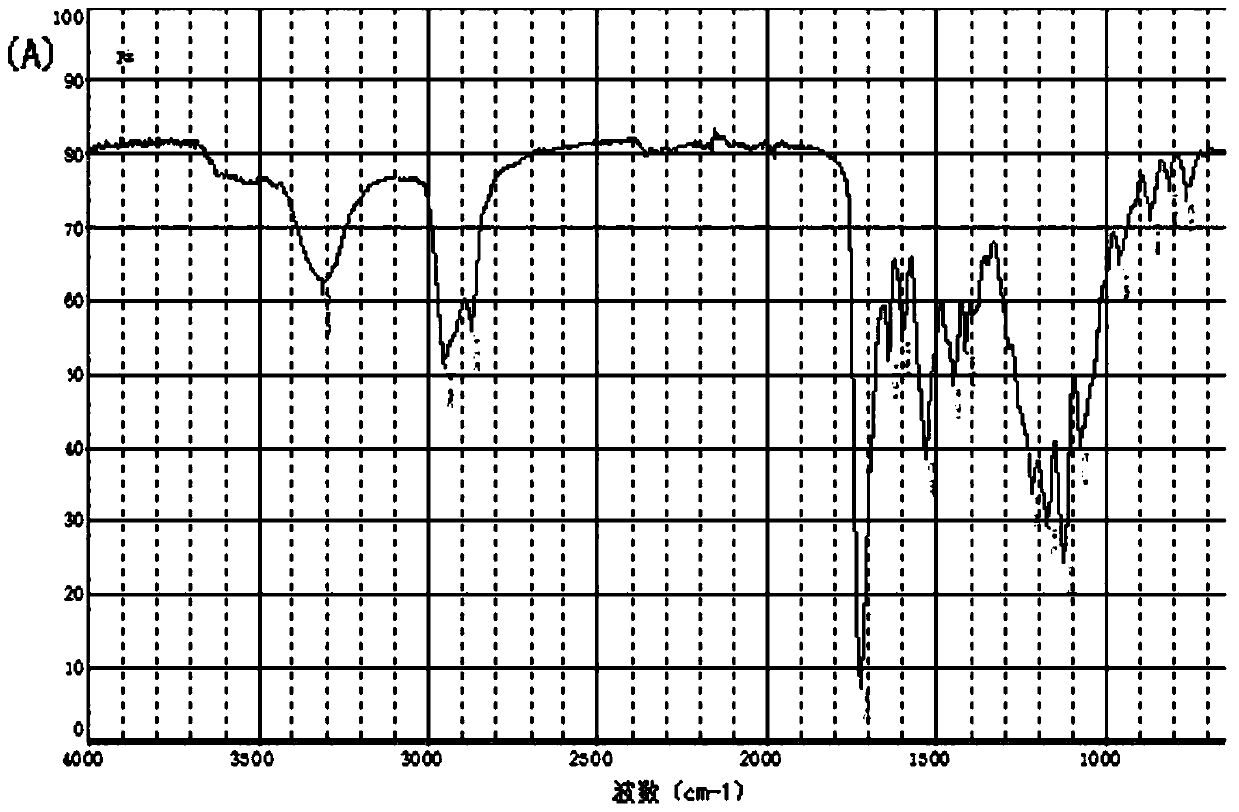

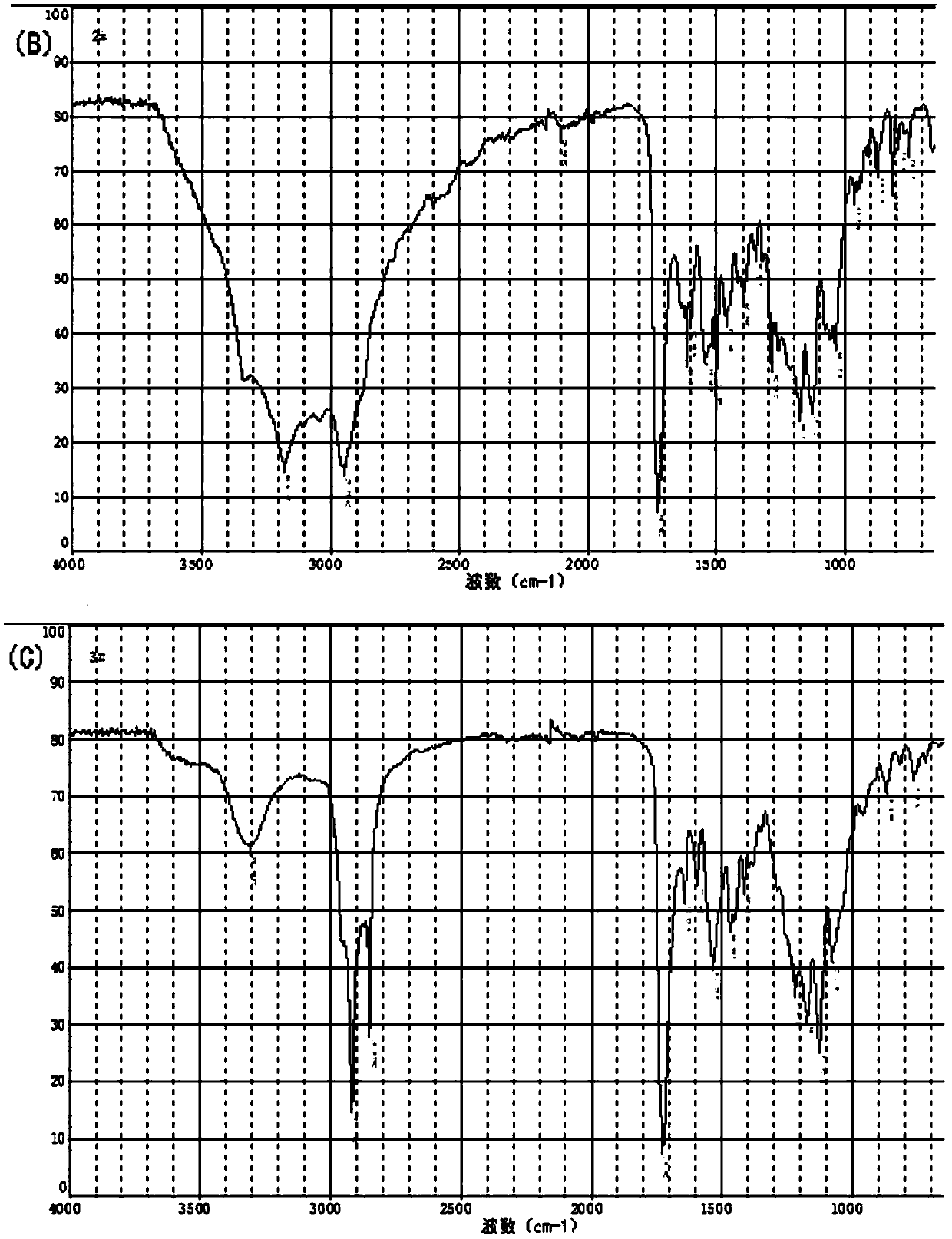

[0053] 1. Preparation of modified polyurethane sponge:

[0054] 1) Prepare 0.01mol / L Tris buffer solution with pH=8.5: Weigh 0.12114g of tris hydroxymethylaminomethane, put it into a clean 100mL beaker, add water to dissolve, and adjust the pH of the Tris buffer solution using concentrated ammonia and a pH meter. Adjust to 8.5;

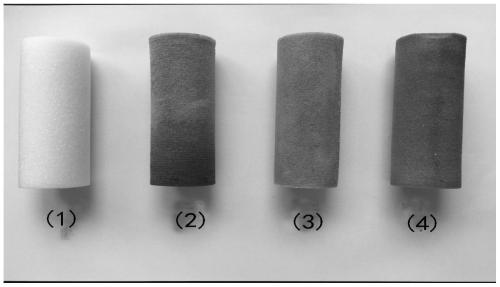

[0055] 2) Pretreatment of polyurethane sponge: place 4-inch (3.5 cm in diameter) cylindrical commercial polyurethane sponge in a 1L beaker, ultrasonically clean it with distilled water and ethanol for 3 times, and then dry it for later use;

[0056] 3) Polymerization reaction: Submerge the pretreated polyurethane sponge in step 2) in 2g / L dopamine solution (0.01mol / L Tris buffer solution configuration), magnetically stir at room temperature for 24h, then take it out and wash it with distilled water, and store it at 60°C Dry to obtain the polymerization product (recorded as: PU-PDA sponge);

[0057] 4) Grafting reaction: immerse the PU-PDA sponge pre...

Embodiment 1

[0071] Simulation of NAPLs contaminated sites:

[0072] Wash the beaker, ordinary quartz sand and cylindrical barbed wire with deionized water, then place the beaker on a ventilated and well-closed platform, pour 200mL of water into the beaker, and put the quartz sand to the 1200mL scale of the beaker After most of the water has settled, add n-hexane dyed with Sudan Red (139.6354g in total), insert a cylindrical barbed wire into the middle of the quartz sand, and finally cap the beaker to simulate NAPLs contaminated sites such as image 3 .

[0073] The method of modified polyurethane sponge repairing non-aqueous organic phase liquid polluted soil:

[0074] Insert a cylindrical PU-PDA-ODA sponge (4 inches in diameter, 3.5 centimeters) prepared above into the wire mesh of the above-mentioned simulated NAPLs-contaminated site, then close the beaker, take it out after standing for 10min, and use tweezers in a closed platform Quickly transfer the sponge to a 200mL beaker, close...

Embodiment 2

[0079] Simulation of NAPLs contaminated sites:

[0080]Wash the cuboid glass cylinder, quartz sand and other materials with deionized water, and then place it on a ventilated and well-closed platform, add 300mL of water, then add quartz sand, let it stand for 1 hour, and then add Sudan red dyed hexamethasone 200mL of alkane (139.6644g in total), and then insert perforated polytetrafluoroethylene tubes (wrapped with barbed wire to simulate the operation well) into the quartz sand in the middle area of the glass cylinder, and use a peristaltic pump to connect the polytetrafluoroethylene tubes to build a circulation pump Inject the leaching system (simulated injection well and extraction well), insert the small polytetrafluoroethylene tube connected to the peristaltic pump into the quartz sand at both ends of the glass cylinder, and insert the silicone tube of the peristaltic pump connected to the polytetrafluoroethylene tube of the simulated injection well. In a large beaker f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com