Power coal and sulfur concentrate sorting method and special device thereof

A sorting and electric coal technology, applied in chemical instruments and methods, magnetic separation, solid separation, etc., can solve the problems of large investment, low calorific value, high operating cost, etc., to meet the follow-up process, reduce production pressure, and improve grade Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Below in conjunction with accompanying drawing and embodiment example, the present invention will be further described:

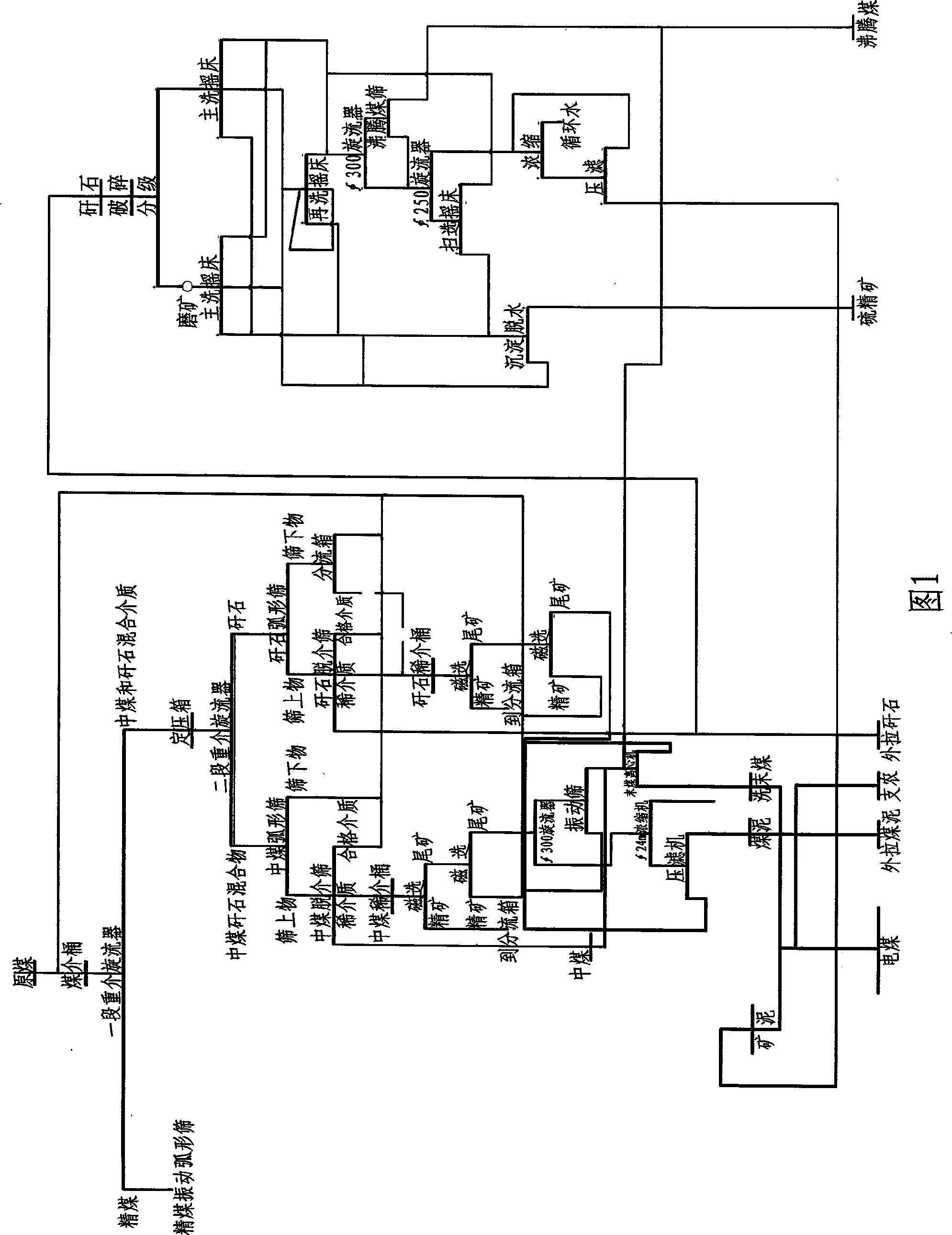

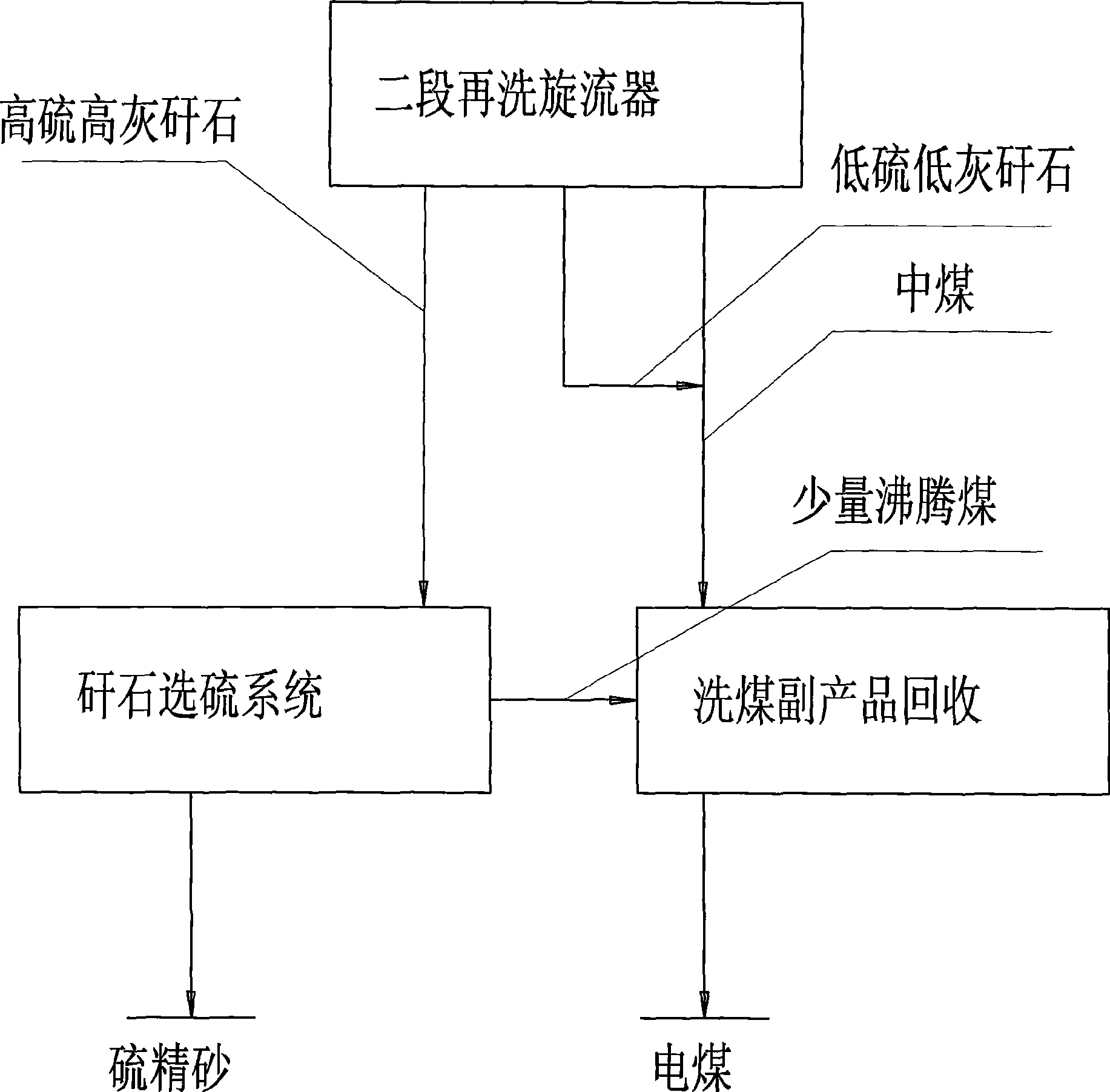

[0052] As shown in Figures 1 and 2, a sorting method for electric coal comprises the steps:

[0053] (1) Sorting the mixture of raw coal and dense medium suspension into a dense medium cyclone to obtain a density of less than 1.5g / cm 3 Clean coal and density greater than 1.5g / cm 3 mixture of medium coal and gangue;

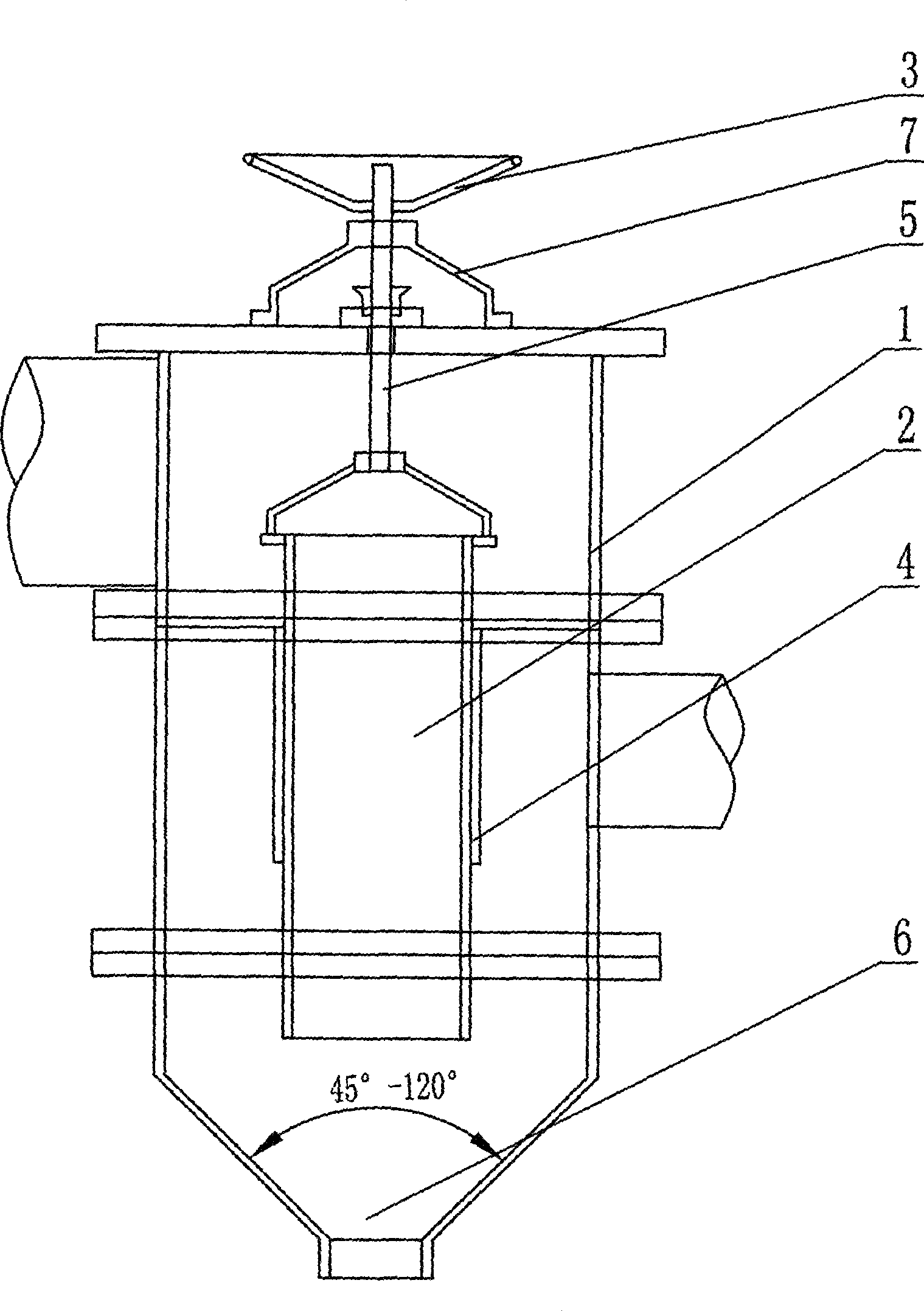

[0054] (2) Sorting the mixture of medium coal and gangue into a dense medium cyclone with a taper of 45°-120° at the bottom outlet to obtain a density of less than 1.8g / cm 3 Medium coal and density less than 2.5g / cm 3 gangue mixture;

[0055] (3) Put the mixture into the medium coal arc sieve for de-intermediation, the under-screen material enters the coal media barrel, and the over-screen material enters the medium coal de-intermediation screen;

[0056] (4) The oversize material that enters the medium coal removal sieve is further...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com