Green production process of biodiesel

A technology for green production and biodiesel, which is applied in the fields of biofuel, petroleum industry, fatty acid production, etc., can solve the problems of acid residue water treatment difficulty, reduce glycerol purity, and high processing cost, so as to reduce environmental protection pressure, reduce production cost, and reduce The effect of production pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

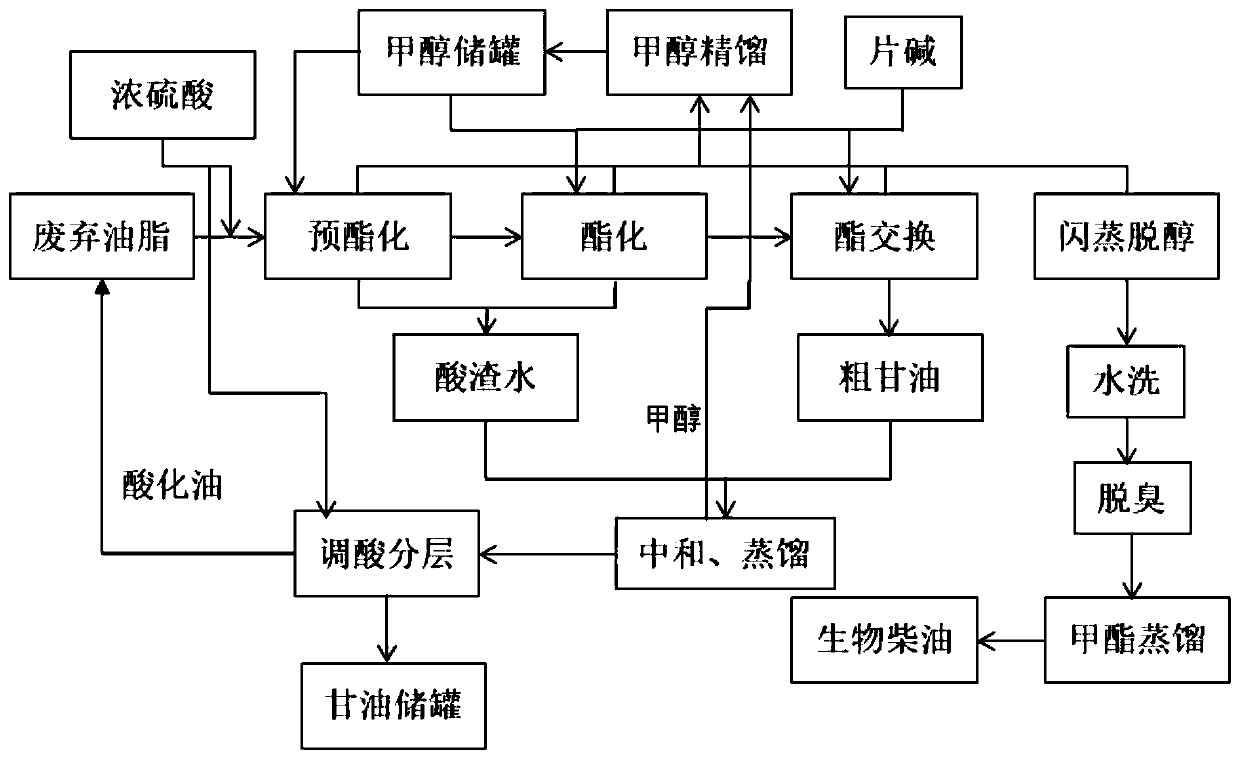

[0033] Such as figure 1 A kind of green production technology of biodiesel shown, comprises the steps:

[0034] (1) Pre-esterification: input methanol, concentrated sulfuric acid (98% sulfuric acid, commercially available) and waste oil (waste oil) into the reactor in sequence. , Blow the waste oil remaining in the pipeline into the reactor with compressed air to avoid clogging the pipeline; control the oil temperature in the reactor at 60°C, react at low temperature for 130 minutes, let it stand for 30 minutes, open the valve at the bottom of the reactor to discharge the acid slag water, collect The acid slag water enters the acid slag water storage tank; the consumption of this step methanol is 18% of the waste oil weight, and the consumption of the concentrated sulfuric acid is 0.3% of the waste oil weight;

[0035] (2) Esterification reaction: raise the temperature of the oil in the reactor to 100°C, start to supply methanol to the reactor under agitation, control the flo...

Embodiment 2

[0044] Such as figure 1 A kind of green production technology of biodiesel shown, comprises the steps:

[0045] (1) Pre-esterification: input methanol, concentrated sulfuric acid (98% sulfuric acid, commercially available) and waste oil (waste oil) into the reactor in sequence. , Blow the waste oil remaining in the pipeline into the reactor with compressed air to avoid clogging the pipeline; control the oil temperature in the reactor at 65°C, react at low temperature for 110 minutes, let it stand for 40 minutes, open the valve at the bottom of the reactor to discharge the acid slag water, collect The acid slag water enters the acid slag water storage tank; the consumption of this step methanol is 20% of the waste oil weight, and the consumption of the concentrated sulfuric acid is 0.8% of the waste oil weight;

[0046] (2) Esterification reaction: raise the temperature of the oil in the reactor to 105°C, start to supply methanol to the reactor under agitation, control the flo...

Embodiment 3

[0055] Such as figure 1 A kind of green production technology of biodiesel shown, comprises the steps:

[0056] (1) Pre-esterification: input methanol, concentrated sulfuric acid (98% sulfuric acid, commercially available) and waste oil (waste oil) into the reactor in sequence. , Blow the waste oil remaining in the pipeline into the reactor with compressed air to avoid clogging the pipeline; control the oil temperature in the reactor at 62°C, react at low temperature for 120 minutes, let it stand for 35 minutes, open the valve at the bottom of the reactor to discharge the acid slag water, collect The acid slag water enters the acid slag water storage tank; the consumption of this step methanol is 19% of the waste oil weight, and the consumption of the concentrated sulfuric acid is 0.5% of the waste oil weight;

[0057] (2) Esterification reaction: raise the temperature of the oil in the reactor to 100°C, start to supply methanol to the reactor under agitation, control the flo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com