Intelligent speed regulation method for belt conveyor based on material monitoring

A belt conveyor, intelligent speed regulation technology, applied in conveyors, conveyor objects, conveyor control devices, etc., can solve the problems of uneven distribution, large load error, large mechanical and conveyor belt friction coefficient, etc. The effect of reducing coal accumulation, reducing energy consumption, speed regulation range and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] The present invention will be further described below in conjunction with accompanying drawing.

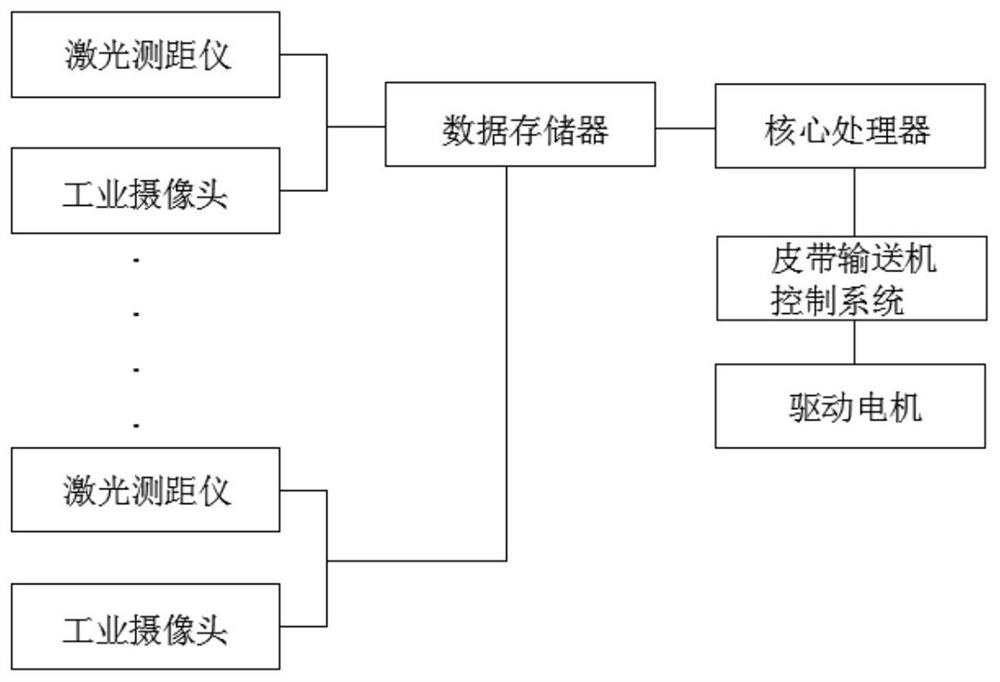

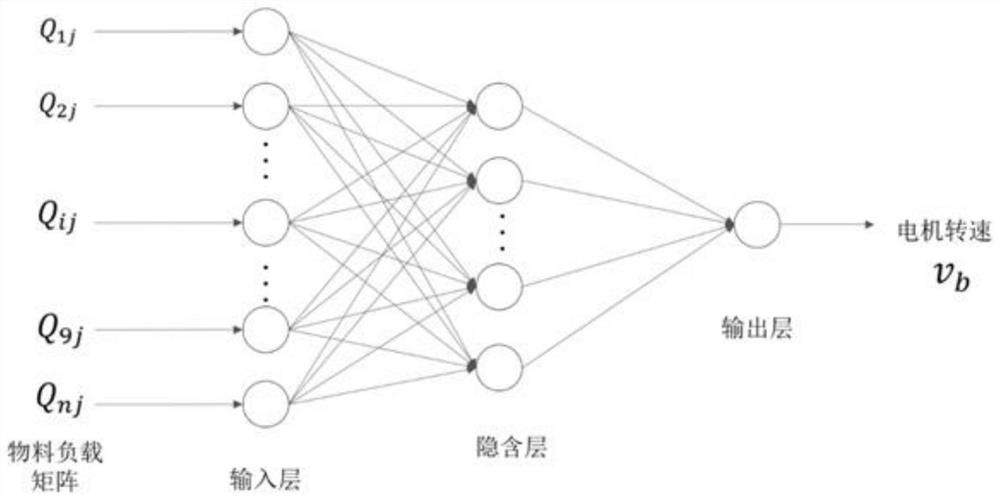

[0070] Such as figure 1 with figure 2 As shown, an intelligent speed regulation method for belt conveyors based on material monitoring, assuming that the transport length of the belt conveyor is L z , and evenly arrange 10 sets of material monitoring devices above a belt conveyor, including the following steps:

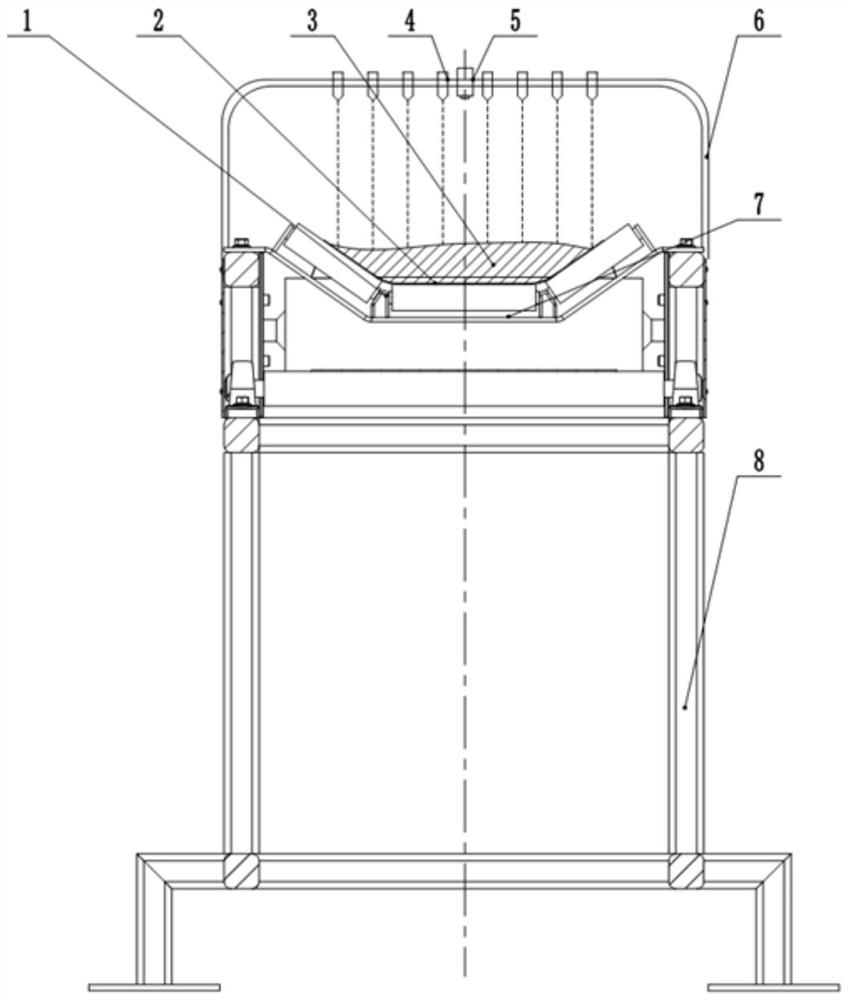

[0071] Step 1: Install the material monitoring device. Install 10 sets of material monitoring devices evenly above the belt conveyor at equal distances. The installation method of each set of material monitoring devices is as follows figure 2 As shown, including the idler roller 1, the conveyor belt 2, the transported material 3, the installation frame 6 is installed on the belt conveyor bracket 8, and the distance between the rack and the idler beam 7 is H, the material monitoring device described 8 laser rangefinders 4 are set, and the layout method of the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com