Motor and AMT (automated mechanical transmission) integration-based electric vehicle driving system and driving method

A technology of electric vehicles and drive systems, applied in the direction of electric vehicles, motors, control drives, etc., can solve the problems of increased volume and quality, shortened motor speed adjustment time, and increased vehicle costs, so as to reduce production and use costs, The effect of overcoming poor adaptability to working conditions and simplifying the shift control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

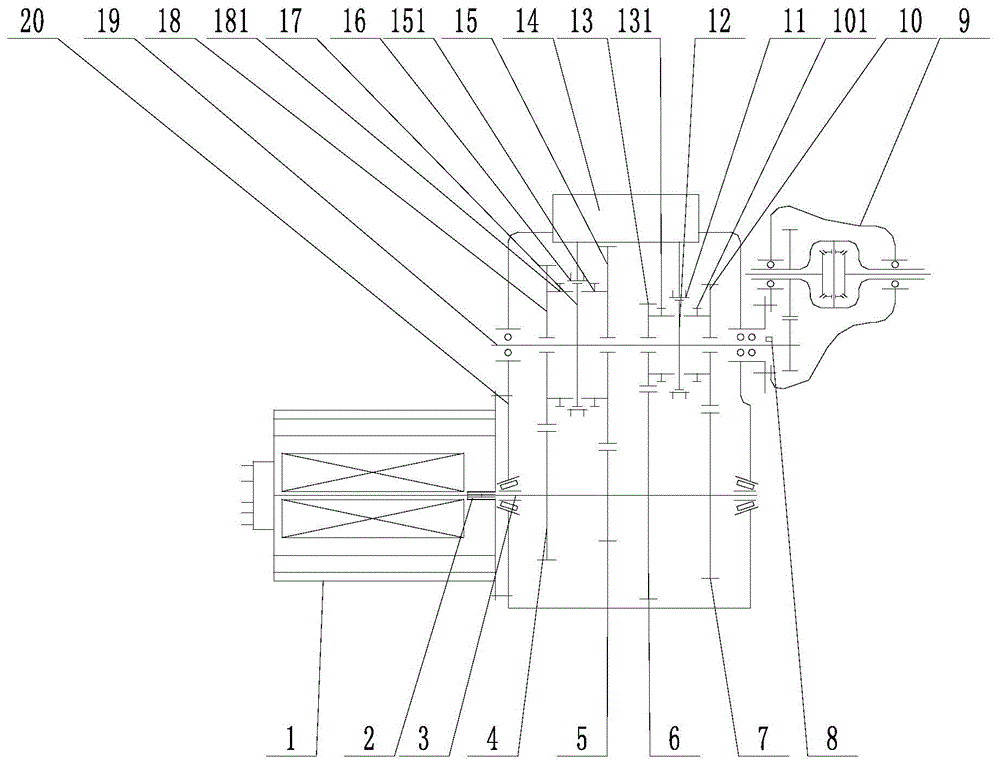

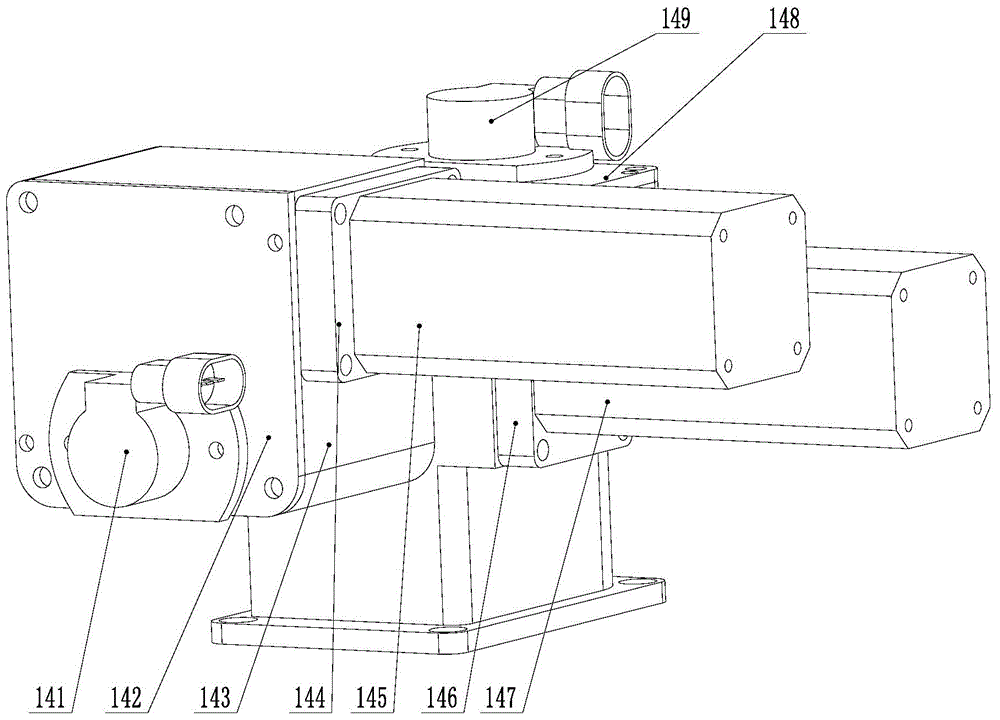

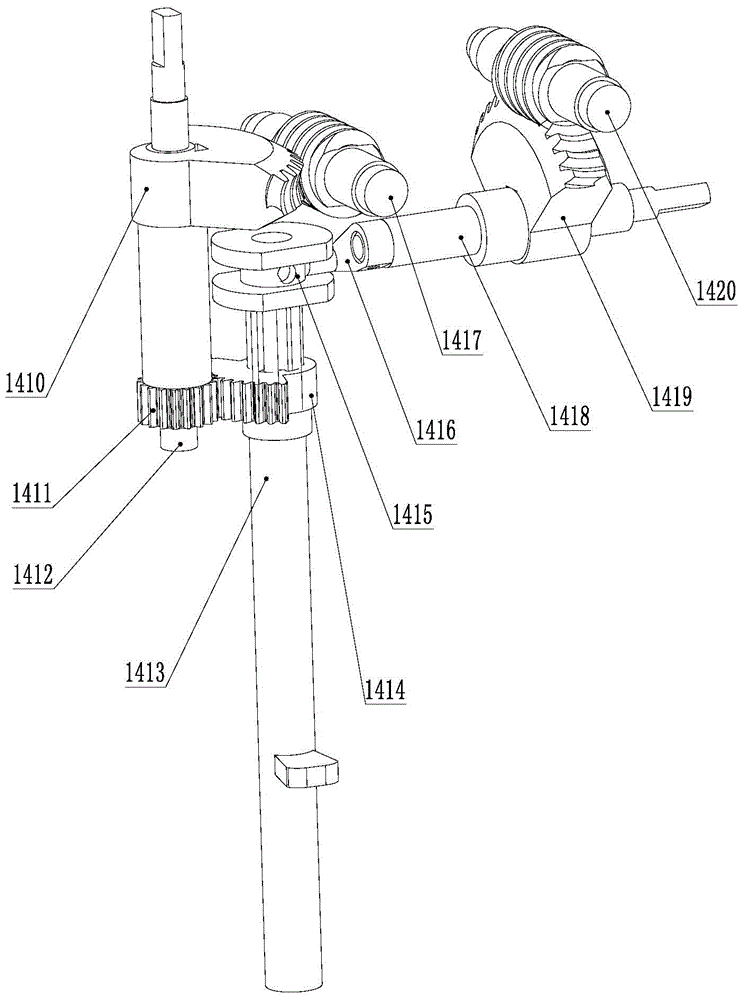

[0049] Such as figure 1 As shown, the electric vehicle driving system based on the integration of motor and AMT mainly includes: a driving motor 1, a transmission, and a gear selection actuator 14; and also includes a drive motor controller and a gear selection actuator controller.

[0050] The driving motor 1 is a DC brushless motor. The driving motor 1 and the transmission case 20 are directly connected by fine-thread screws after being positioned by fixed pins through an integrated design, eliminating the need for a clutch. Maintenance and repair, and make the structure more compact, more suitable for small pure electric vehicles with front and front drive drive motors. The output shaft of the drive motor is provided with an internal spline, which is denoted as the motor internal spline output shaft 2.

[0051] Described speed changer comprises speed changer casing 20, speed changer input shaft 3, the driving gear of four gears (first gear driving gear 5, second gear driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com