Disc-type permanent magnetic coupling mechanism and devices using same

A permanent magnet coupling, disc technology, applied in electromechanical devices, permanent magnet clutches/brakes, electric brakes/clutches, etc. High speed regulation accuracy, wide speed regulation range, easy to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

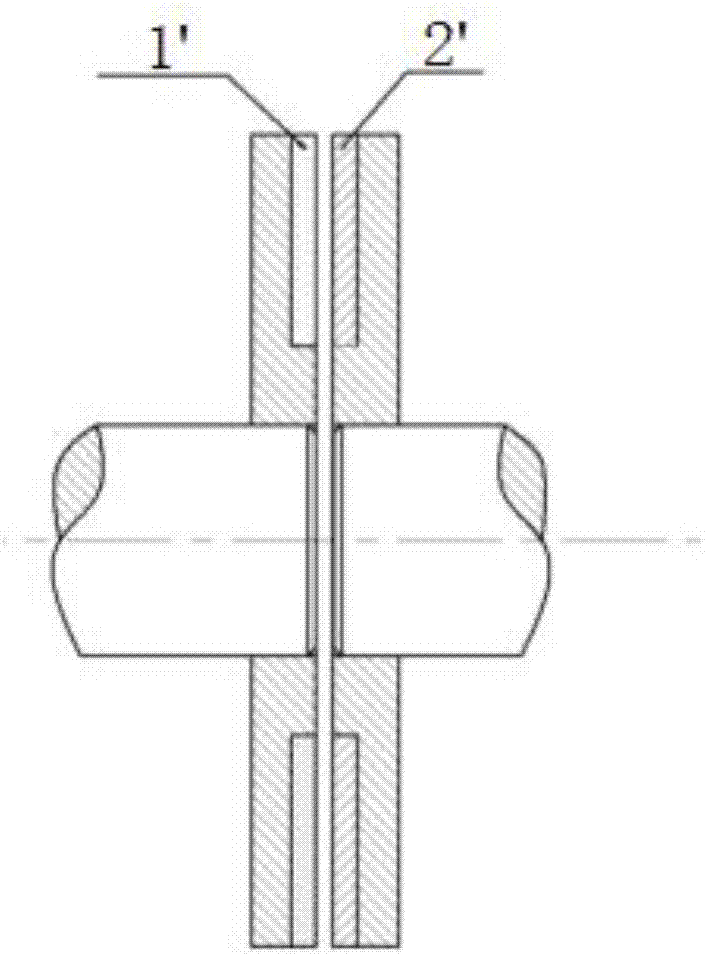

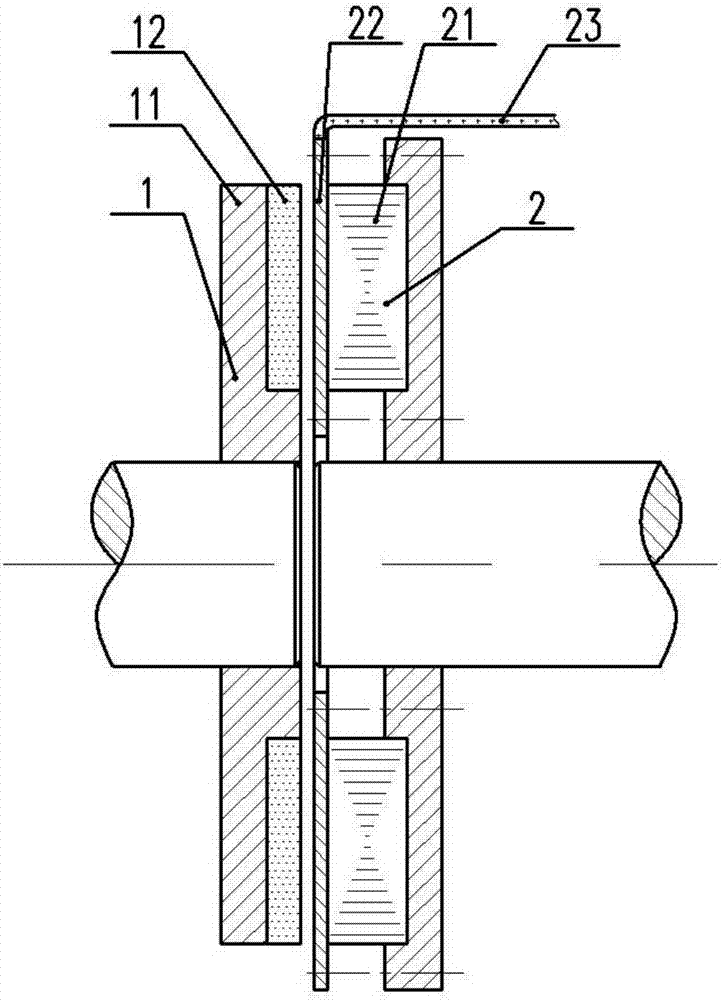

[0095] like Figure 3-5 As shown, a preferred embodiment of the present invention relates to a disk-type permanent magnet coupling mechanism, which includes a permanent magnet rotor 1 and a conductor rotor 2 . An air gap is provided between the permanent magnet rotor 1 and the conductor rotor 2 , and relative rotation can occur between the permanent magnet rotor 1 and the conductor rotor 2 .

[0096] The permanent magnet rotor 1 includes a permanent magnet rotor core 11 and a permanent magnet 12 , and the permanent magnet 12 is arranged on the permanent magnet rotor core 11 . like Figure 4 As shown, the arrangement of the permanent magnets 12 is that N and S poles are arranged alternately. The permanent magnet rotor can be surface-mounted or embedded.

[0097] The conductor rotor 2 includes a conductor rotor core 21 , a copper disk 22 and lead wires 23 , the copper disk 22 is arranged on the surface of the conductor rotor core 21 , and the copper disk 22 is connected to th...

Embodiment 2

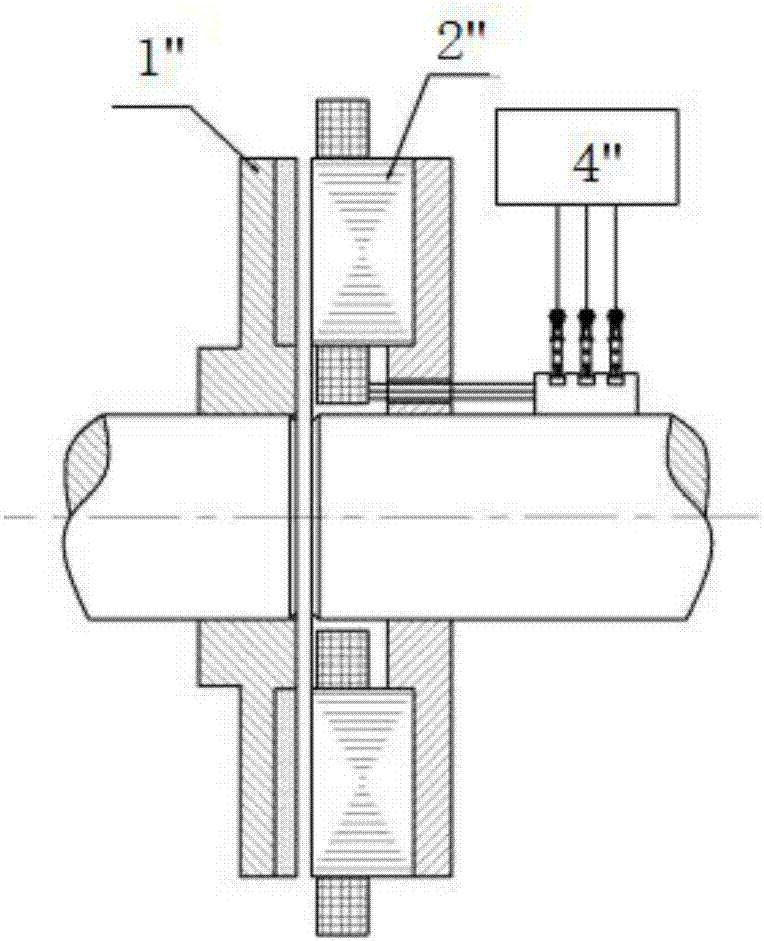

[0114] The present invention also relates to a disc-type permanent magnet coupling governor, which uses the aforementioned disc-type permanent magnet coupling structure, such as Image 6 As shown, it includes a first shaft 5, a permanent magnet rotor 1 that rotates synchronously with the first shaft 5, a second shaft 6, a conductor rotor 2 that rotates synchronously with the second shaft 6, a current extraction device 3 and a control unit 4, and the permanent magnet There is an air gap between the rotor 1 and the conductor rotor 2 , and relative rotation can occur between the permanent magnet rotor 1 and the conductor rotor 2 .

[0115] The lead wire 23 is connected to the control unit 4 via the current extraction device 3 .

[0116] The current extraction device may be a slip ring and a carbon brush, or a rotary transformer, or other devices capable of extracting current from a rotating conductor.

[0117] The control unit 4 can control the current or voltage of the conducto...

Embodiment 3

[0119] The present invention also relates to a magnetic coupling speed regulating device for constant power operation, which uses the aforementioned disk-type permanent magnetic coupling structure, such as Figure 7 As shown, it includes a first shaft 5, a permanent magnet rotor 1 and a second permanent magnet rotor 8 that rotate synchronously with the first shaft 5, a second shaft 6, a conductor rotor 2 that rotates synchronously with the second shaft 6, a stator 7, and a current The extraction device 3 and the control unit 4"'. The aforementioned disk-type permanent magnetic coupling structure constitutes a first electromagnetic induction assembly, and the stator 7 and the second permanent magnet rotor 8 constitute a second electromagnetic induction assembly.

[0120] The second permanent magnet rotor 8 and the permanent magnet rotor 1 are fixedly arranged on the first shaft 5, the second permanent magnet rotor 8 includes a second permanent magnet and a second permanent magne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com