Hydraulic speed regulating valve

A technology of speed control valve and hydraulic pressure, which is applied in the field of hydraulic speed control valves to achieve the effects of reducing energy consumption, avoiding oil leakage, and maintaining stable speed control range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

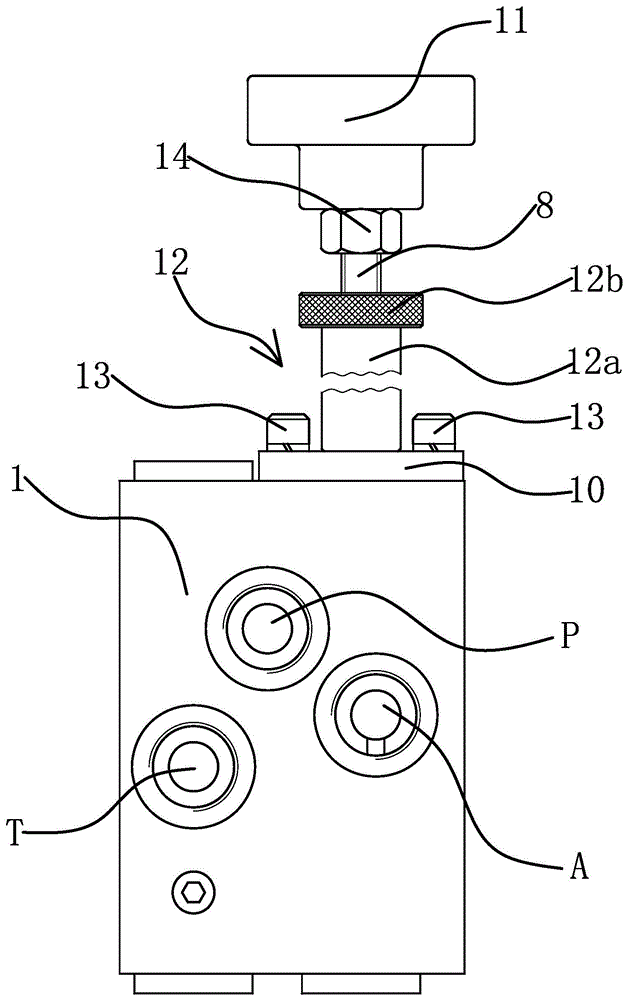

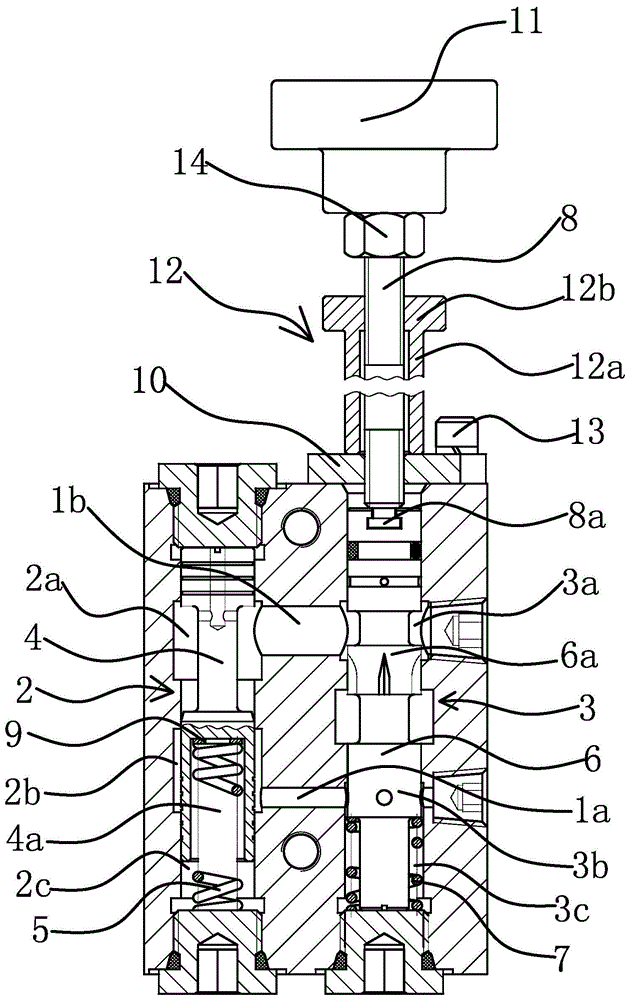

[0033] The hydraulic speed regulating valve includes a valve body 1, a fixed differential overflow valve chamber 2, a throttle valve chamber 3, a fixed differential overflow valve core 4, a throttle valve core 6 and a speed regulating valve stem 8.

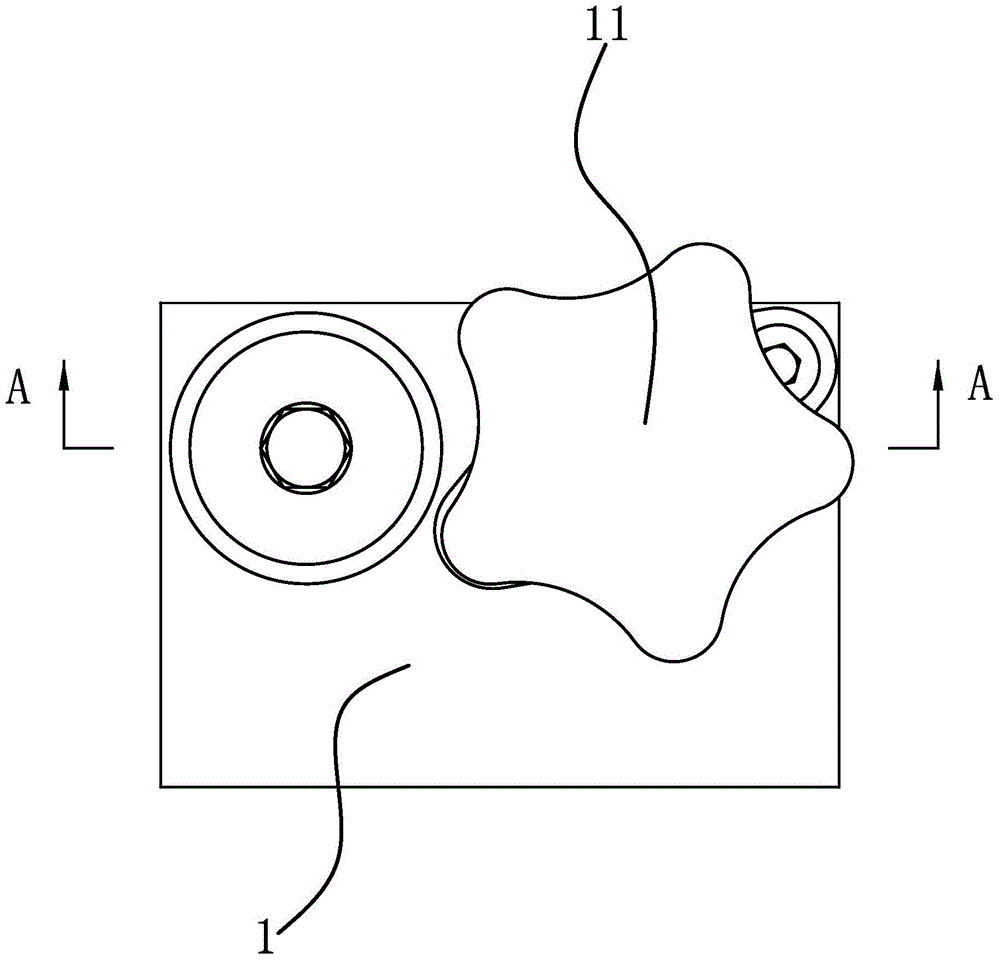

[0034] As a specific implementation, such as figure 2 with image 3 As shown, the differential relief valve cavity 2 and the throttle valve cavity 3 are set in the valve body 1 respectively. In this embodiment, the differential relief valve cavity 2 and the throttle valve cavity 3 are arranged parallel to each other. Body 1, after the processing is completed, it is blocked by plugging. The structure and processing method of the valve body 1 maximize the use of the space in the valve body 1, so that the volume of the hydraulic speed regulating valve can be made smaller. Such as figure 1 As shown, the valve body 1 is also provided with an oil inlet P, an oil return port T and a working port A.

[0035] Such as image 3 As sho...

Embodiment 2

[0054] The technical solution in this embodiment is basically the same as that in the first embodiment, the difference is that in this embodiment, the differential relief valve cavity 2 and the throttle valve cavity 3 are located in two independent valve bodies 1 . It should be noted that as an evolution of the technical solution, as long as the connection method is the same as the technical solution to be protected by the claims, even if the differential relief valve cavity 2 and the throttle valve cavity 3 are arranged in two independent valve bodies 1 ( For example, the differential relief valve and throttle valve sold in the market are connected in series), and it should also be considered that this solution falls within the protection scope of the claims of the present application.

Embodiment 3

[0056] The technical solution in this embodiment is basically the same as that in Embodiment 1, the difference is that in this embodiment, the hydraulic speed regulating valve is applied to agricultural machinery. Agricultural machinery refers to various machinery used in crop planting and animal husbandry production, as well as in the primary processing and handling of agricultural and animal products. The agricultural machinery used in the crop planting industry can be divided into farming machinery, planting machinery and harvesting machinery according to their functions. The most typical of the farming machinery is the rotary tiller, and the most typical of the harvesting machinery is the combine harvester.

[0057] The mechanical structure of agricultural machinery in the planting industry includes the walking mechanism that drives the agricultural machinery to move on the field and the actuator used to complete the plowing, planting, and harvesting actions. For example, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com