Cold-box core shooter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with accompanying drawings and specific preferred embodiments, so that the advantages and features of the present invention can be more easily understood by those skilled in the art. range is limited.

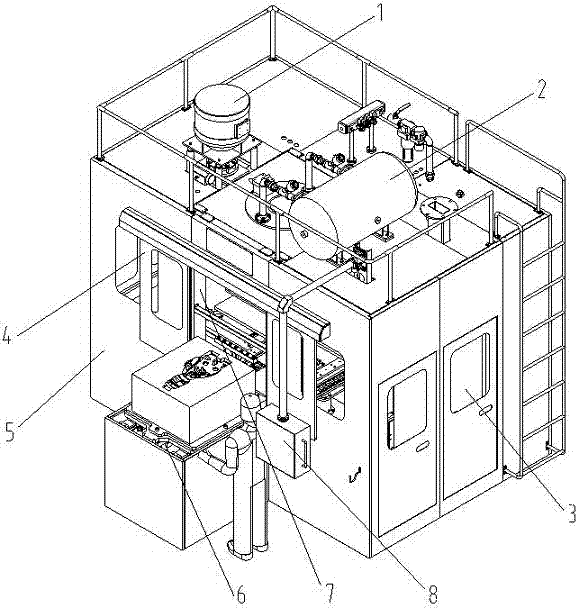

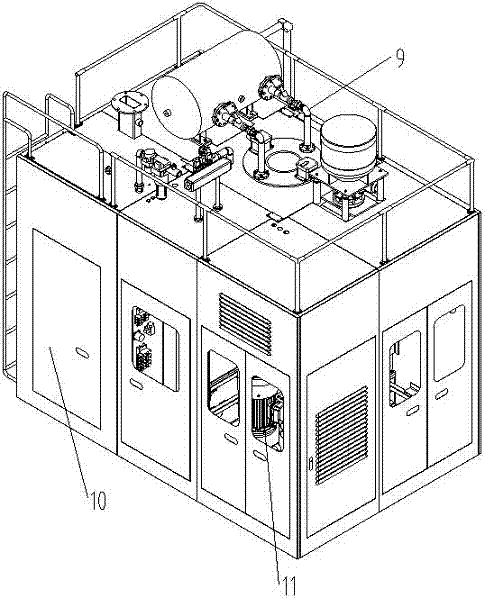

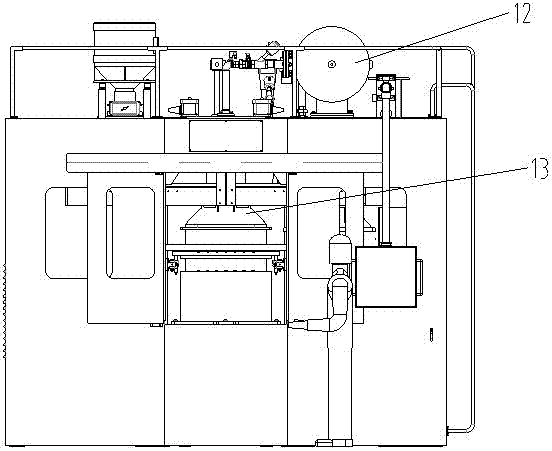

[0020] see Figure 1 to Figure 4 , the cold box core shooting machine of the present invention includes: a sand shooting mechanism 12, an electrical part 3, a machine base 7, a gas generator 10, a hydraulic system 11 and a surrounding screen 5, and the electrical part 3, the machine base 7, and the gas generator 10 and the hydraulic system 11 are all located in the enclosure 4, which occupies a small area. The user only needs to connect the main line and the air source to the equipment to start production. It is easy to keep the equipment clean and easy to maintain, ensuring the safety of the operating environment. An opening is provided on the front side wall of the screen 5, and a sliding door 4 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com