Frequency conversion, speed regulation and comprehensive electrical control system for electric locomotive

An electrical control system and frequency conversion speed regulation technology, which is applied to locomotives and other directions, can solve the problems of low starting traction performance, long shutdown time, large starting impact, etc., and achieve the effect of perfecting protection function, saving electric energy and improving starting efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

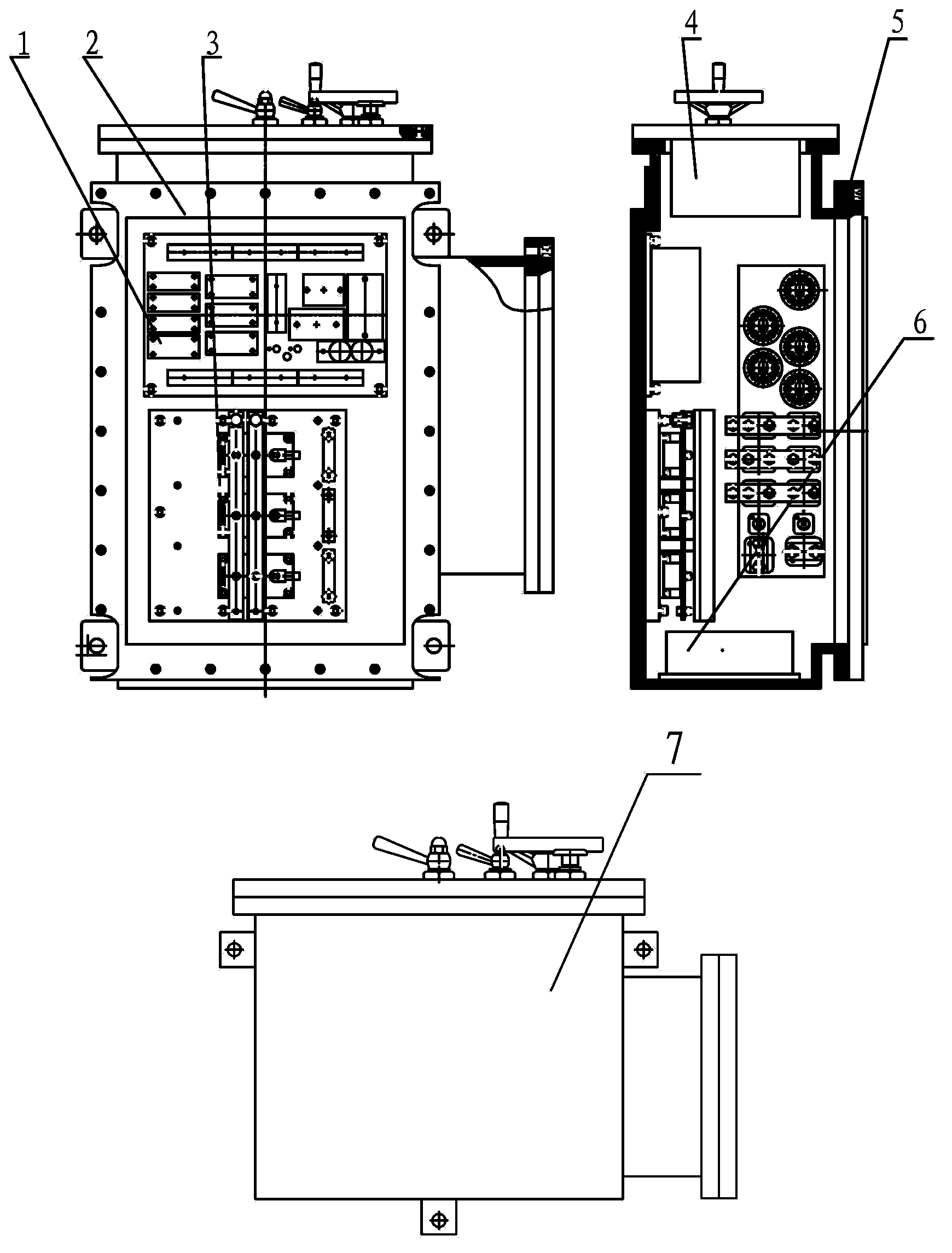

[0023] The structure diagram of the main engine of the frequency conversion and speed regulation integrated electrical control system of the electric locomotive is as follows: figure 1 shown. The control system includes a control electrical assembly board 1 , a main cavity assembly 2 , a frequency conversion system assembly 3 , a control operating system assembly 4 , a main cover assembly 5 , and a power assembly board 6 . like figure 1 As shown, first install the control electrical summary board 1 and the frequency conversion system assembly 3 on the main cavity assembly 2 through mounting screws. After the above process is completely and correctly installed, install the main cover assembly 5 and the control operating system assembly 4. On main chamber assembly 2.

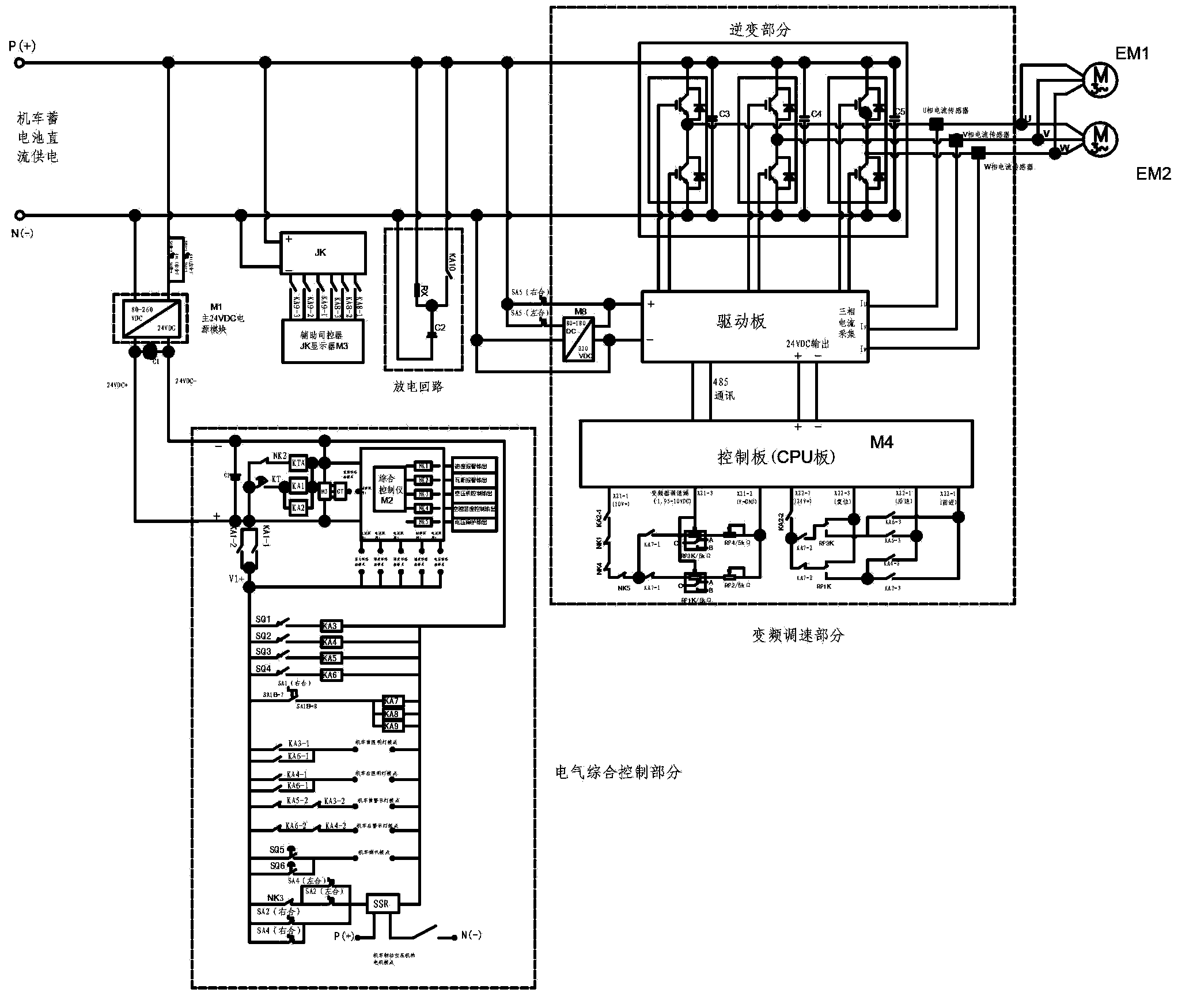

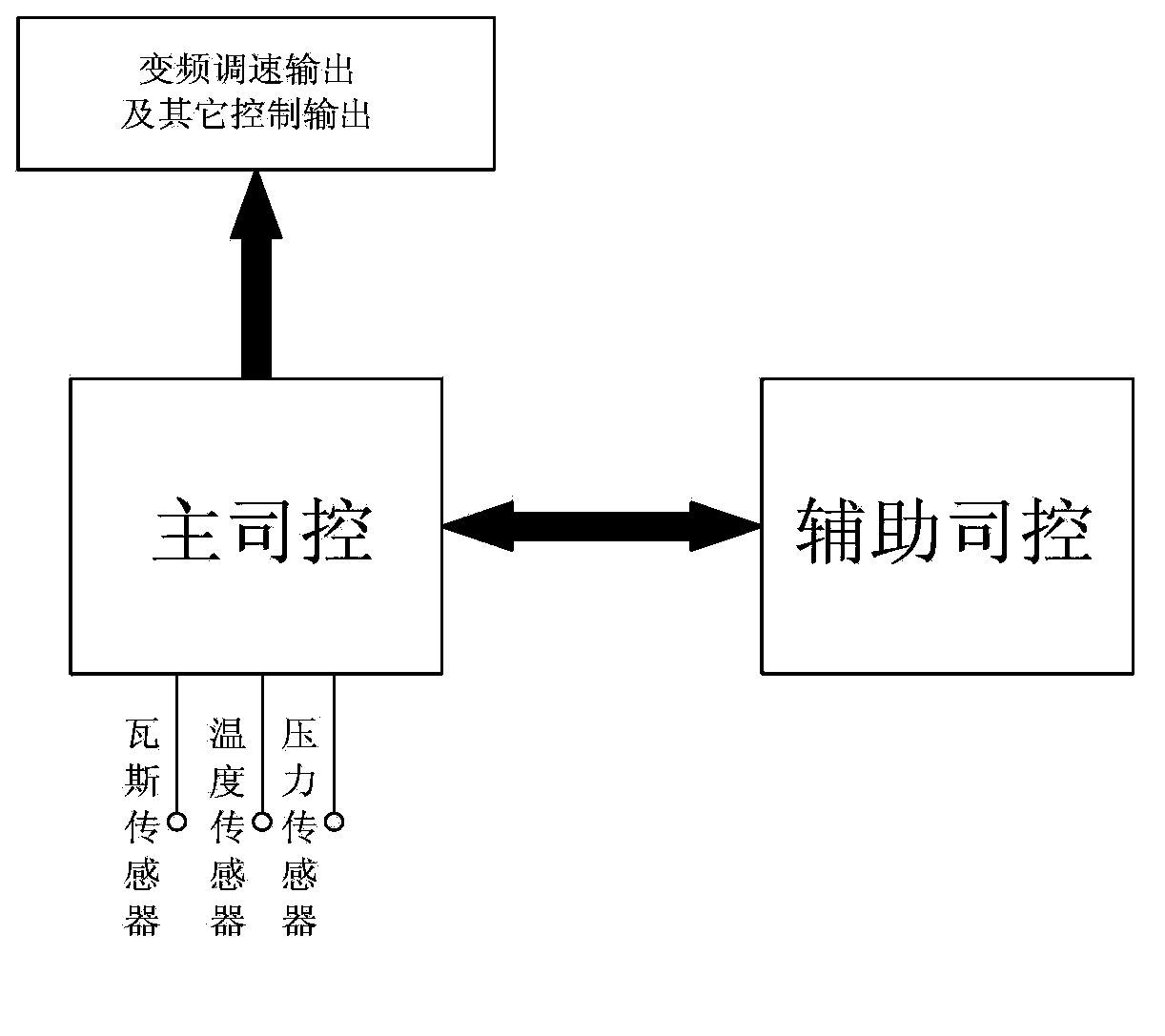

[0024] The working principle of the control system is shown in the figure 2 shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com