Water pump durability test-bed

A durability test and water pump technology, applied in pump testing, liquid variable capacity machinery, liquid cooling, etc., can solve problems such as low degree of automation, low test accuracy, and poor anti-interference ability, and achieve strong anti-interference ability , flexible assembly and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

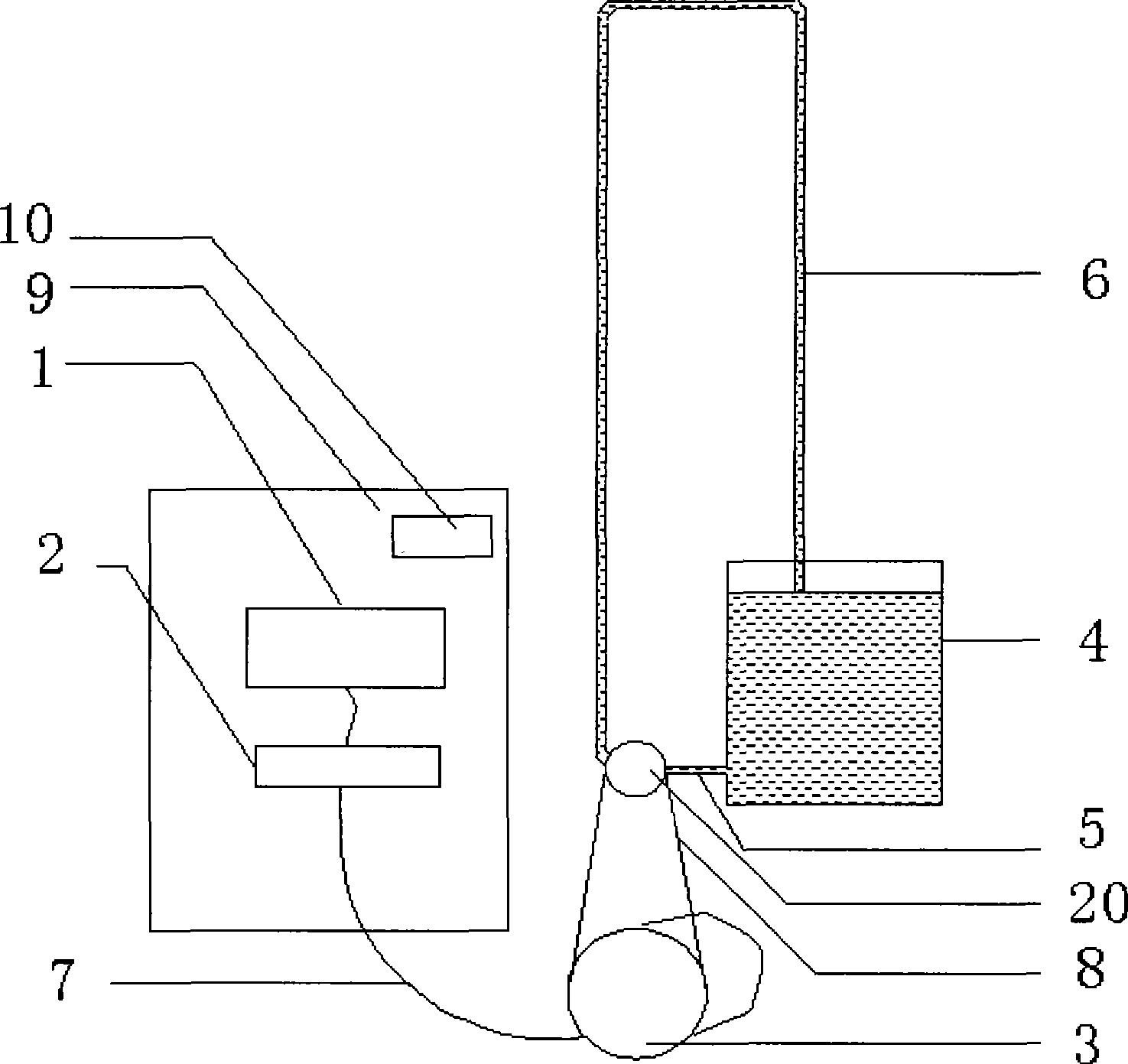

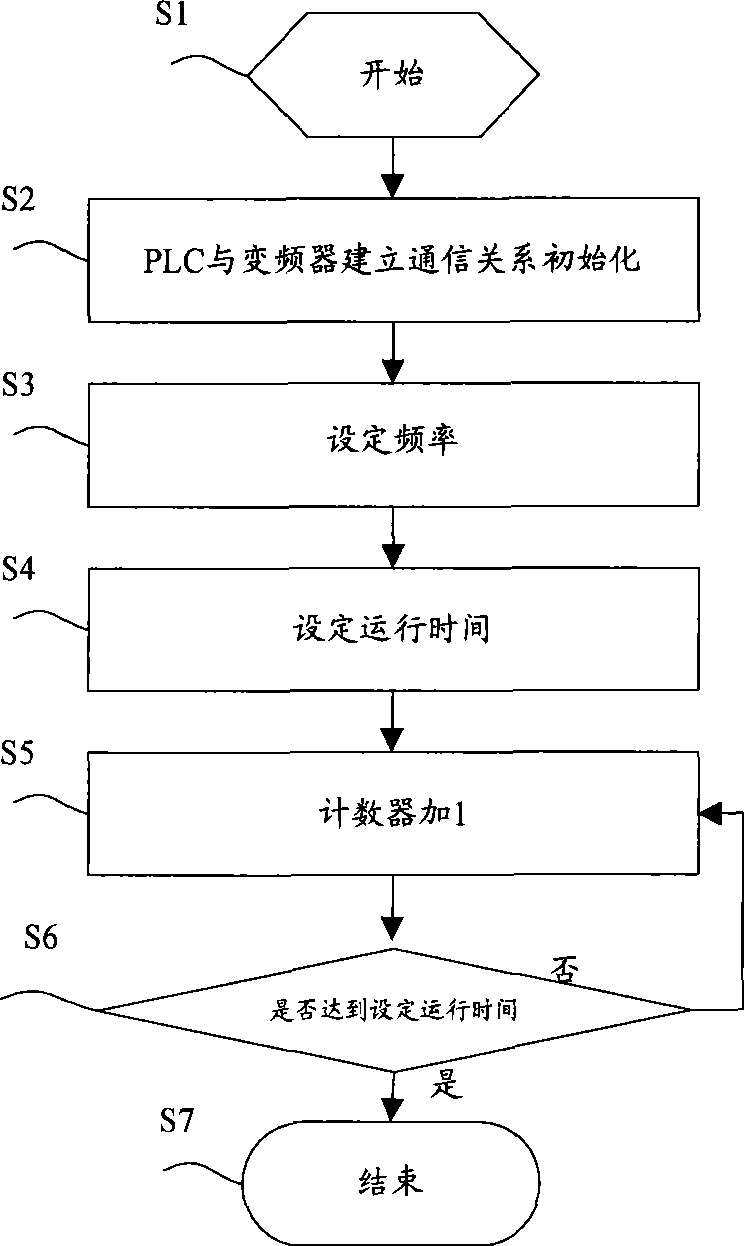

[0020] figure 1 The shown water pump durability test bench of the present invention comprises: a programmable logic controller 1 (ProgrammableLogical Controller, PLC), a frequency converter 2, a frequency conversion motor 3, a water tank 4, a first water pipe 5, a second water pipe 6, a workbench (not shown in the figure) shown), fixtures (not shown). The fixture fixes the water pump 20 on the workbench; the first water pipe 5 is respectively connected to the water inlet of the water pump 20 and the water outlet of the water tank, and one end of the second water pipe 6 is connected to the water pump outlet, and the other end is inserted into the water tank Among 4; the programmable controller 1, the frequency converter 2, and the frequency conversion motor 3 are sequentially connected through the cable 7, and the frequency conversion motor 3 can drive the water pump 20 to run through the belt 8.

[0021] like figure 1 As shown, in the water pump durability test bench of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com