Three-phase single-section/double-section multiple-pole switching reluctance motor

A technology of switched reluctance and electric motors, which is applied in the direction of electrical components, electromechanical devices, and static components of magnetic circuits, etc. It can solve the problems of no progress in switched reluctance motors, lagging industrialization and applied research work, etc., and achieve easy heat dissipation , The effect of increasing the magnetic energy area and reducing the heat load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accompanying drawing and embodiment the present invention will be further described

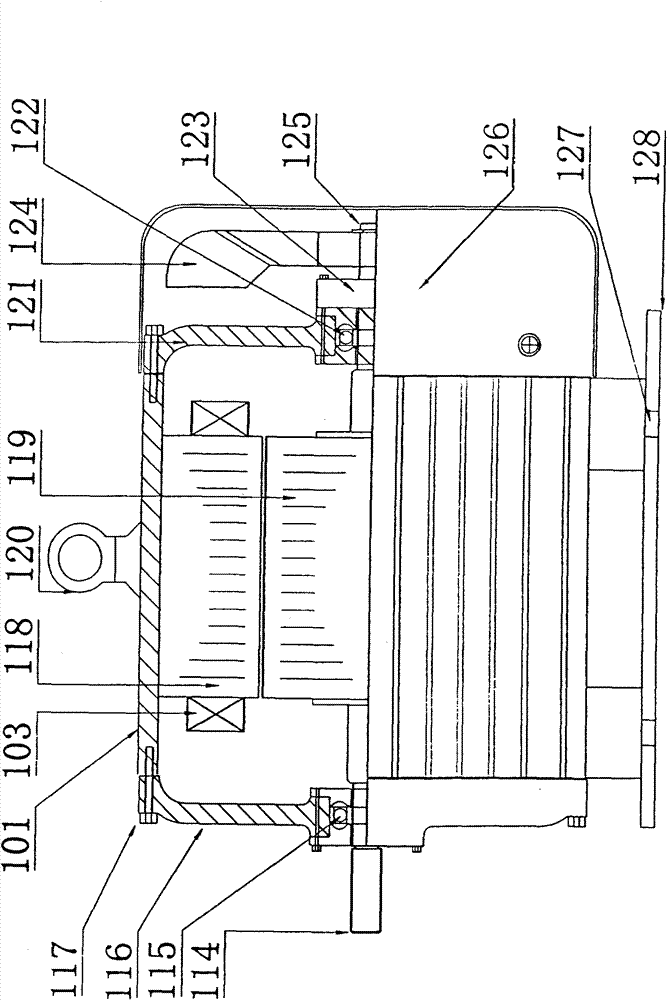

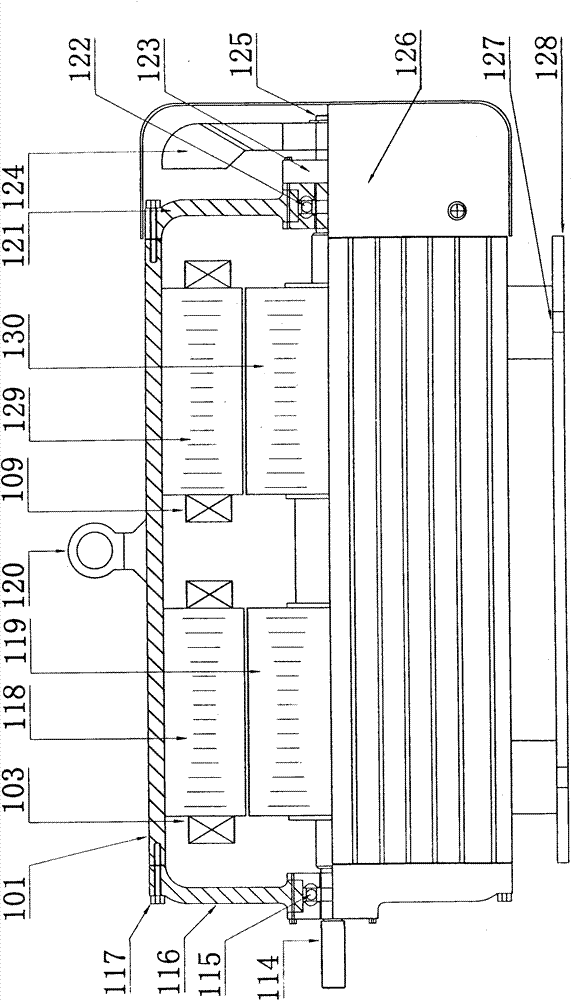

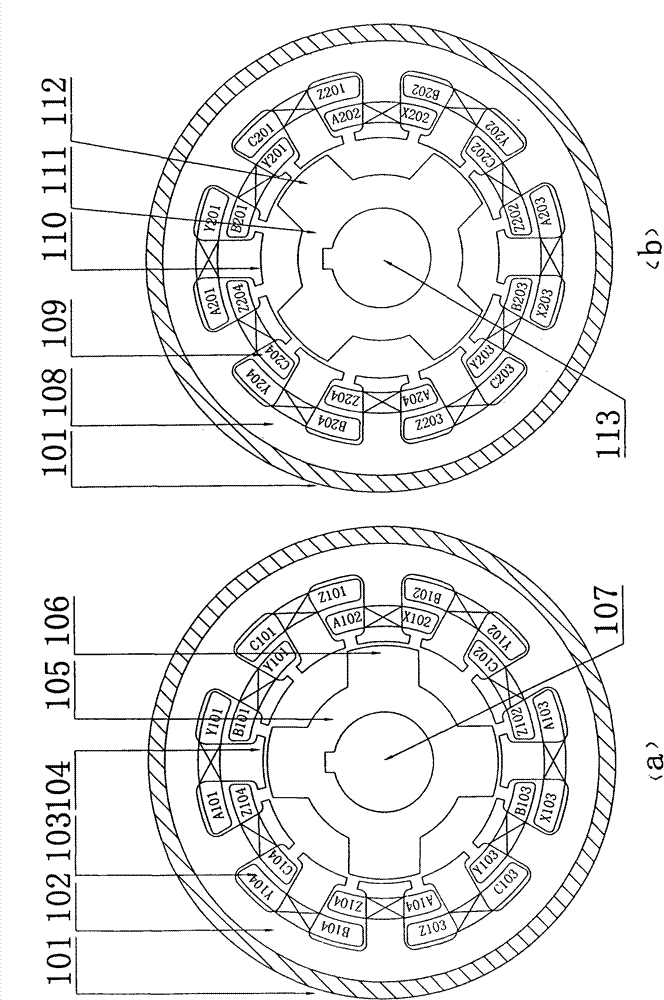

[0043] refer to figure 1 , a three-phase single-stage double-pole switched reluctance motor in the figure, including a motor housing 101 placed on a motor base 128, a motor suspension ring 120 is provided in the middle of the motor housing 101, a motor front end cover 116 and a motor rear end cover 121 respectively It is arranged at both ends of the motor shaft 114, and a rotor is arranged between the motor front end cover 116 and the motor rear end cover 121. The motor rear end cover 121 is provided with a motor fan cover 126, and a motor fan is arranged inside the motor fan cover 126. 124, an electronic sensor 123 is arranged between the motor rear end cover 121 and the motor fan 124, and the motor is further composed of a double salient pole structure stator and rotor formed by laminating silicon steel sheets; its stator core includes the first section of s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com