Energy-consumption steel-frame block filled wall

A technology for filling walls and steel frames, applied to walls, building components, and earthquake resistance, can solve problems such as wall extrusion damage, and achieve the effects of improving deformation capacity, facilitating large-scale promotion, good deformation capacity and ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in further detail below in conjunction with specific embodiments, but the protection scope of the present invention is not limited by the specific embodiments, and the claims shall prevail. In addition, on the premise of not violating the technical solution of the present invention, any modification or change made to the present invention that can be easily realized by those skilled in the art will fall within the scope of the claims of the present invention.

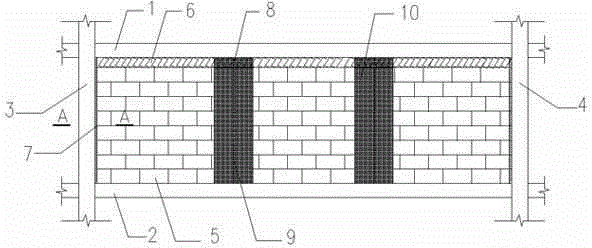

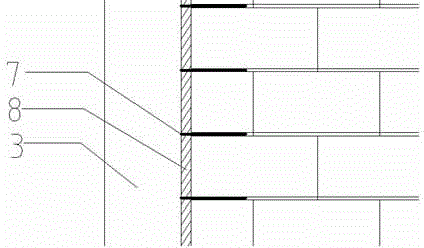

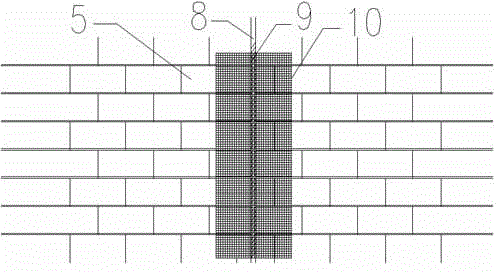

[0024] Such as figure 1 : An energy-consuming steel frame block filling wall, including an upper steel frame beam 1, a lower steel frame beam 2, a left steel frame column 3, a right steel frame column 4 and a block filling wall 5 constituting a frame structure. The filling wall 5 includes autoclaved aerated concrete blocks, concrete hollow blocks, gypsum blocks, and fly ash blocks. When the infill wall 5 is built, vertical joints 8 are reserved between the steel frame colu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com