Thin-wall braking sleeve of direct drive rotary table and manufacturing method

A turntable and thin-walled technology, applied in the field of direct-drive turntables, can solve the problems of brake failure of thin-walled sleeves, elastic deformation of thin-walled sleeves, waste of energy, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

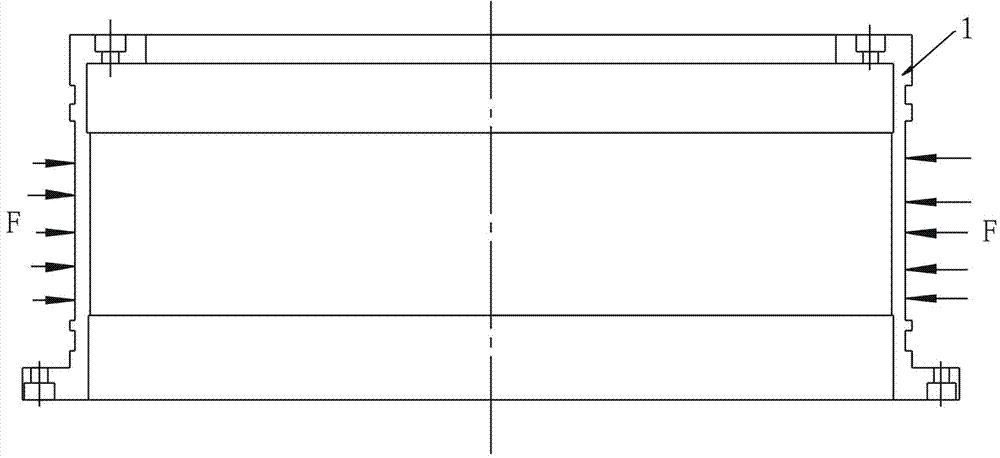

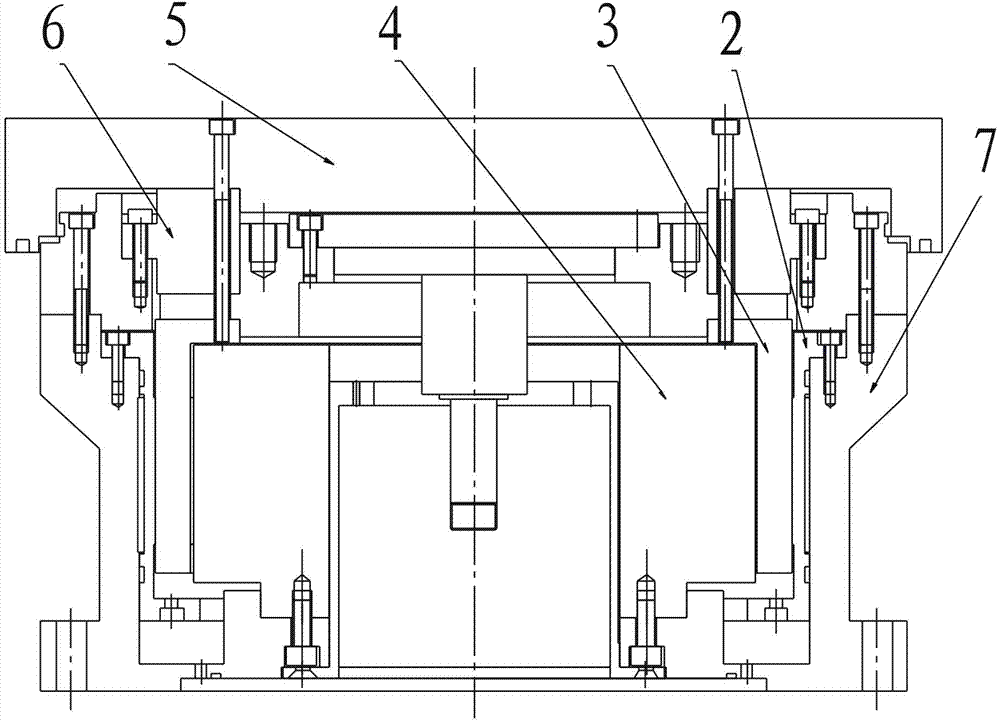

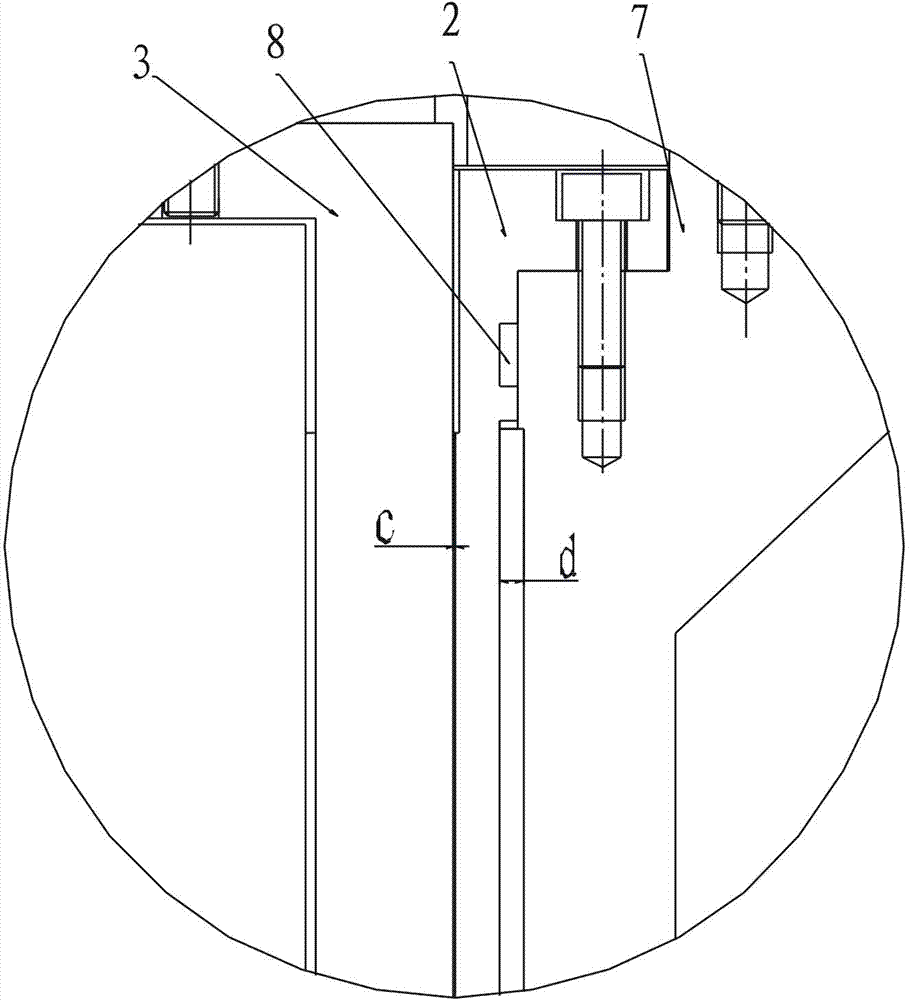

[0033] Such as Figure 2-4 As shown, the thin-walled brake sleeve 2 of the direct drive turntable implemented according to the present invention is arranged between the motor rotor and the housing 7 of the direct drive turntable; the workbench 5 of the direct drive turntable is driven by the motor through the turntable bearing 6; the motor rotor It is the servo motor rotor assembly 3, and the inside of the rotor is the servo motor stator assembly 4; the main body of the thin-walled brake sleeve 2 is an annular cylinder, and the upper end surface and the lower end surface of the annular cylinder protrude oppositely to form an outer shell that matches the shell 7 shoulders. Stretching edge, the stretching edge at the upper end face and the lower end face are all fixed on the shell 7; The outer gap d is set, and the inner gap c is set between the inner edge of the oval ring and the outer wall of the motor rotor; the outer gap d is larger than the inner gap c, and the outer gap d ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com