Dropping-resisting anti-thunder socket

A plug-in, drop-resistant technology, which is applied to the parts, electrical components, coupling devices, etc. of the connection device, can solve the problem that the lightning protection plug-in does not have the drop-resistant performance, and achieve the effect of good elasticity and good buffering effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

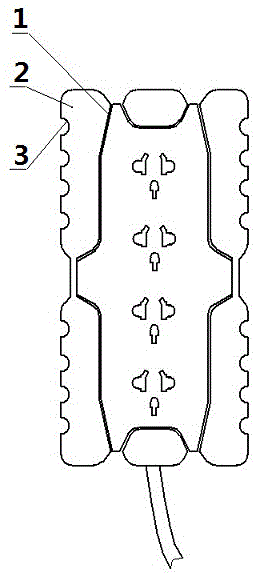

[0014] The present invention provides such as figure 1 The drop-resistant lightning protection plug-in strip shown includes a PC shell 1, and the four corners of the PC shell are respectively injection-molded with buffer layers 2, and the buffer layers 2 are higher than the PC shell, and the buffer layer 2 Thickness is greater than PC case 1. No matter what angle the lightning protection strip falls on the ground, the first thing that touches the ground is the buffer layer. The buffer layer has good elasticity and good cushioning effect, which plays a role in protecting the lightning protection strip from falling.

[0015] In order to make the lightning protection plug-in strip fully resistant to falling, the buffer layer 2 covers the front, side and back of the PC case 1 .

Embodiment 2

[0017] On the basis of Embodiment 1, the side of the PC case 1 of the drop-resistant lightning protection plug-in strip is also provided with a plurality of grooves 3, so that the casing is more likely to undergo elastic deformation, and the overall drop resistance of the lightning protection plug-in strip is enhanced. performance.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com