Chrome-plated board, manufacturing method thereof and crown cap

A manufacturing method and chrome plating technology, applied in the field of steel rolling, can solve the problems of unstable performance, reduced strip elongation, and difficulty in meeting the requirements, and achieve the effects of enhancing cold forming performance, shortening production processes, and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

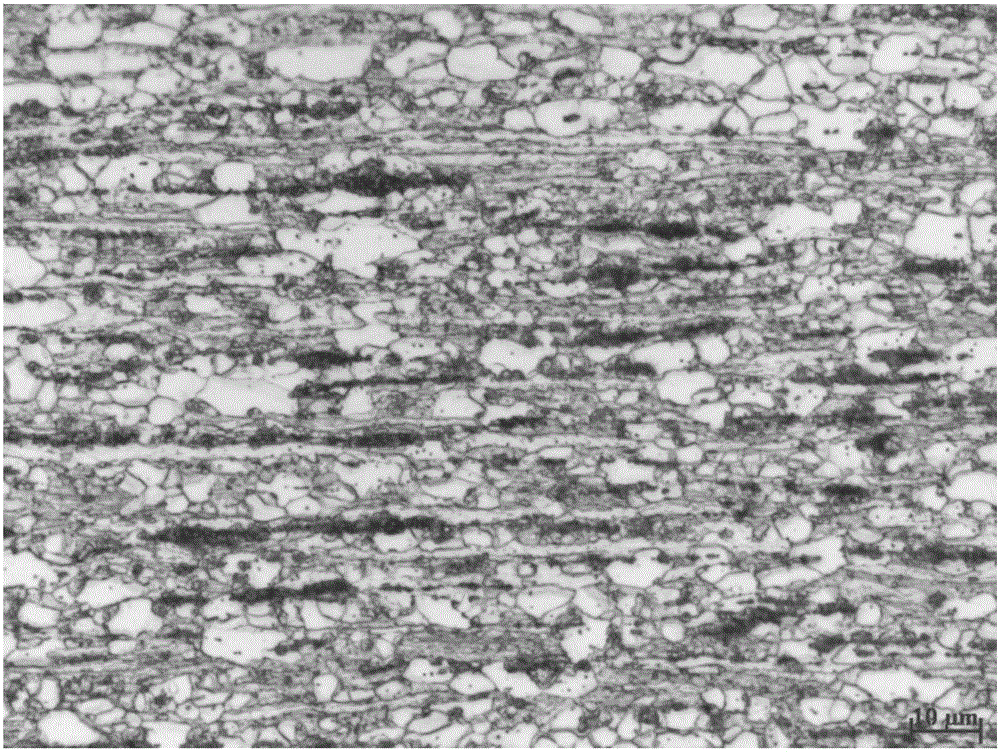

Image

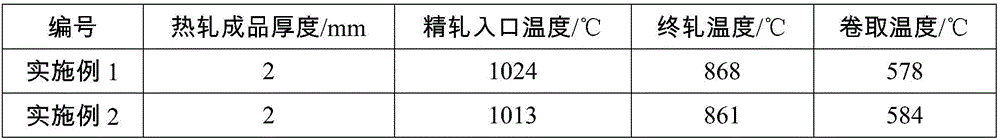

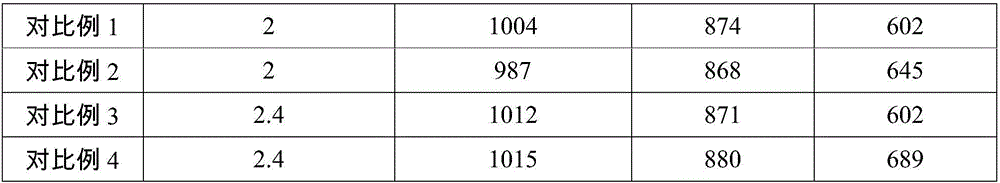

Examples

Embodiment Construction

[0032] The mass percent of the chemical composition of the high-hardness chrome-plated sheet provided in this example is: C: 0.05-0.09%, Si: 0.005-0.02%, Mn: 0.2-0.6%, Al: 0.02-0.06%, P≤0.02%, S ≤0.015%, N≤0.006%, the rest is Fe and unavoidable impurities

[0033] The effect of alloying elements contained in the application and the selection specific analysis instructions of its consumption are as follows:

[0034] C: 0.05-0.09%

[0035] In the high-hardness chromium plating base, C is an important strengthening element, which ensures the strength of the strip through solid solution strengthening and precipitation strengthening. However, as the carbon content increases, the stamping performance of the strip will deteriorate. In order to ensure the hardness of the chrome-plated plate and avoid steelmaking in the peritectic region (C: 0.09-0.13%), the high-hardness chrome-plated substrate of the present invention controls the C content between 0.05-0.09%.

[0036] Si: 0.005-0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com