Round steel with excellent corrosion resistance and delayed fracture resistance for bolt and production method of round steel

A delayed fracture resistance and production method technology, which is applied in the field of steel for fasteners, can solve the problems of increased hydrogen-induced delayed fracture and unsatisfactory anti-corrosion effect, so as to reduce the amount of hydrogen, avoid the deterioration of delayed fracture resistance, and inhibit corrosion pits generated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0049] The round steel for bolts with excellent corrosion resistance and delayed fracture resistance of this embodiment adopts the production process of the present invention, and its process parameters are: the pure degassing time is 20 minutes during the vacuum degassing of the RH furnace; During this time, the target temperature of molten steel in the tundish is stably controlled at 15°C above the liquidus temperature; the heating temperature is 950°C when the high-quality bar heating furnace is heated, and the billet stays in the furnace for 140 minutes; the starting temperature of the round steel is 910°C, and the final The rolling temperature was 780°C. When the round steel is inspected for mechanical properties, its heating temperature is 900°C when it is quenched and heated in the heat treatment process, and its tempering temperature is 580°C when it is tempered at a high temperature.

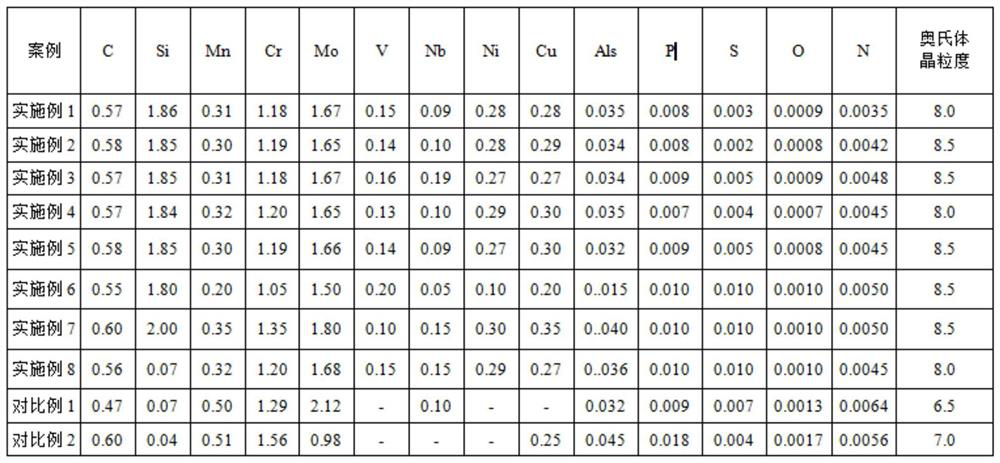

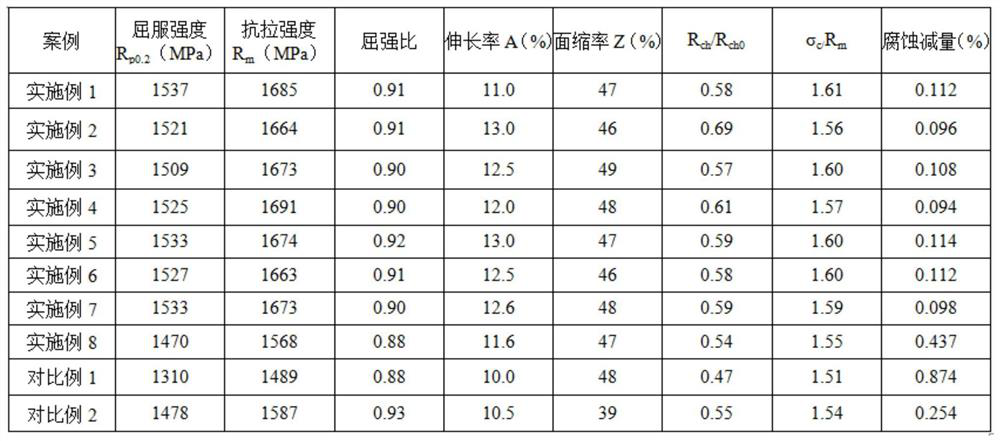

[0050] The chemical composition and content that present embodiment adopts see fig...

Embodiment 2

[0052] The round steel for bolts with excellent corrosion resistance and delayed fracture resistance of this embodiment adopts the production process of the present invention, and its process parameters are: the pure degassing time is 20 minutes during the vacuum degassing of the RH furnace; The target temperature of molten steel in the tundish is stably controlled at 20°C above the liquidus temperature; when the heating furnace is heated, the heating temperature is 1000°C, and the billet stays in the furnace for 170 minutes; the starting rolling temperature of the round steel is 920°C, and the finishing rolling temperature is It is 840°C. When the round steel is inspected for mechanical properties, its heating temperature is 920° C. when it is quenched and heated in the heat treatment process, and its tempering temperature is 600° C. when it is tempered at a high temperature.

[0053] The chemical composition and content that present embodiment adopts see figure 1 , the test...

Embodiment 3

[0055] The round steel for bolts with excellent corrosion resistance and delayed fracture resistance of this embodiment adopts the production process of the present invention, and its process parameters are: the pure degassing time is 20 minutes during the vacuum degassing of the RH furnace; The target temperature of molten steel in the tundish is stably controlled at 18°C above the liquidus temperature; when the heating furnace is heated, the heating temperature is 960°C, and the billet stays in the furnace for 150 minutes; the starting rolling temperature of the round steel is 890°C, and the finishing rolling temperature is is 800°C. When the round steel is inspected for mechanical properties, its heating temperature is 910°C when it is quenched and heated in the heat treatment process, and its tempering temperature is 600°C when it is tempered at a high temperature.

[0056] The chemical composition and content that present embodiment adopts see figure 1 , the test resul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com