Offshore wind power single pile-friction cone composite foundation and construction method thereof

An offshore wind power and composite foundation technology, applied in infrastructure engineering, construction, etc., can solve the problems of wind turbine stability, difficult boulder detection, slow construction progress, etc., to improve the overall horizontal bearing capacity, reduce tilt deformation, The effect of improving the horizontal bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

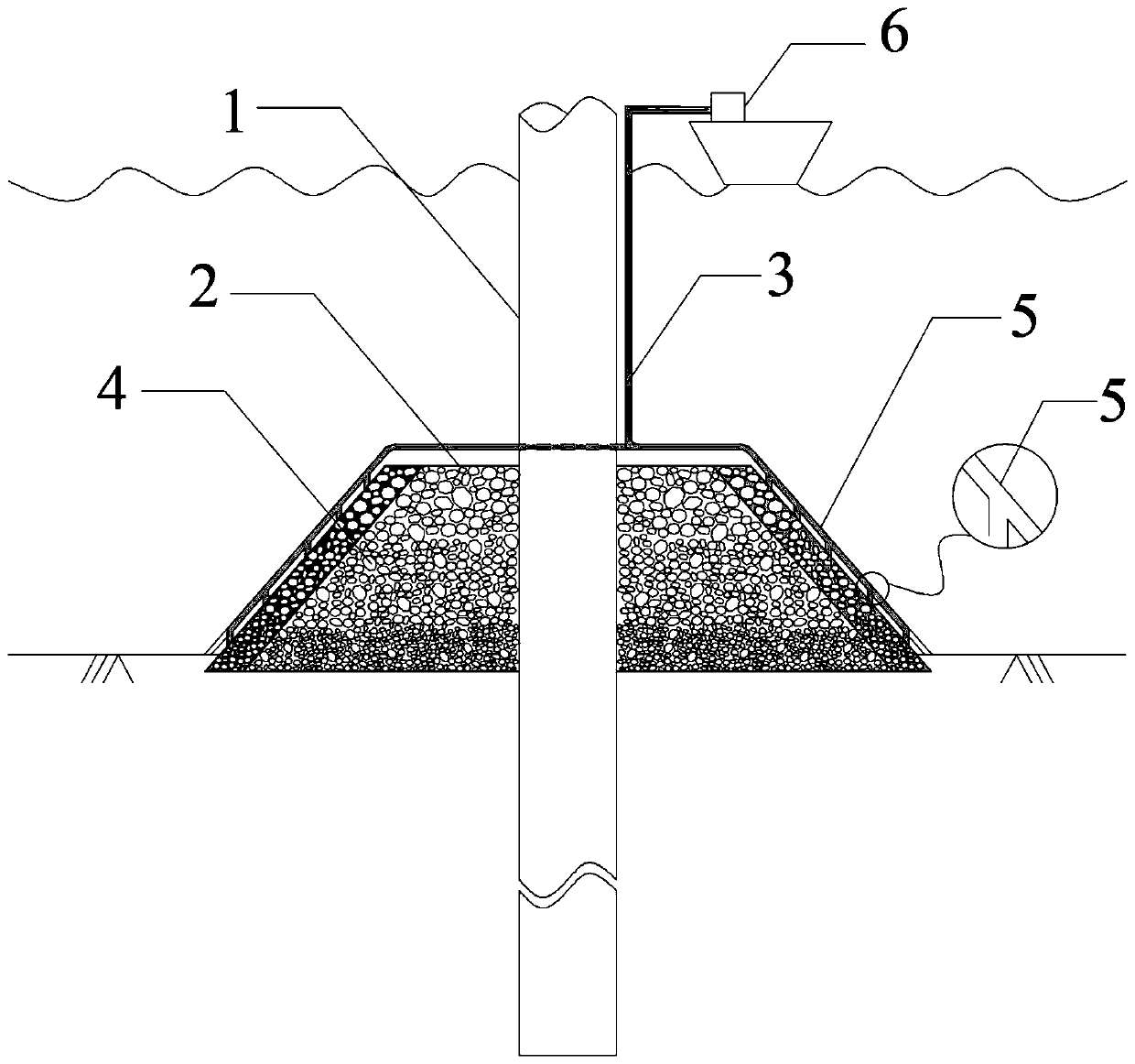

[0043] In another aspect of the present invention, the present invention proposes a construction method for offshore wind power single pile-friction cone composite foundation. According to an embodiment of the present invention, refer to image 3 , the construction method mainly includes the following steps:

[0044] S1: Use the existing large-diameter single pile driving equipment to carry out single pile 1 construction;

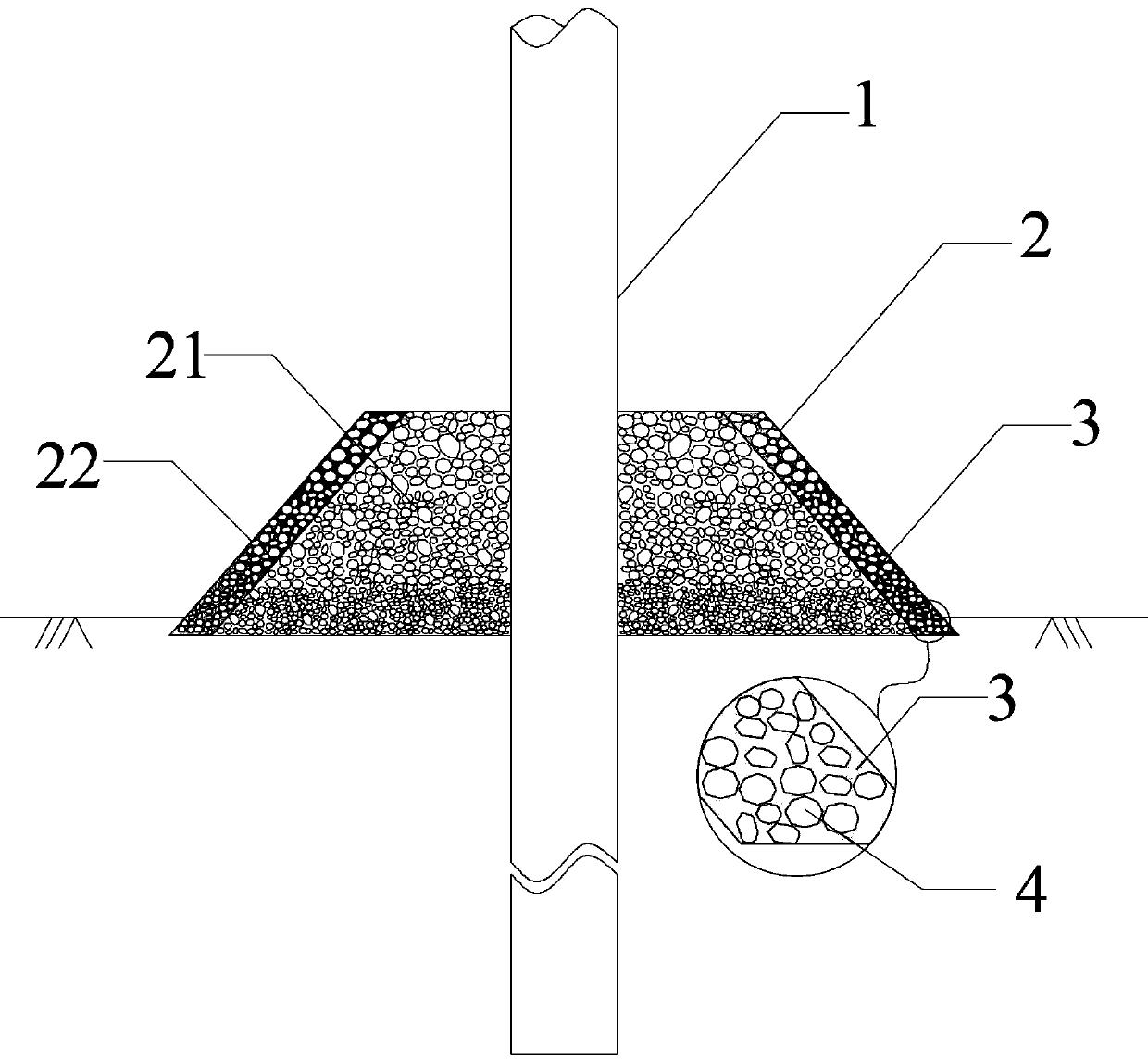

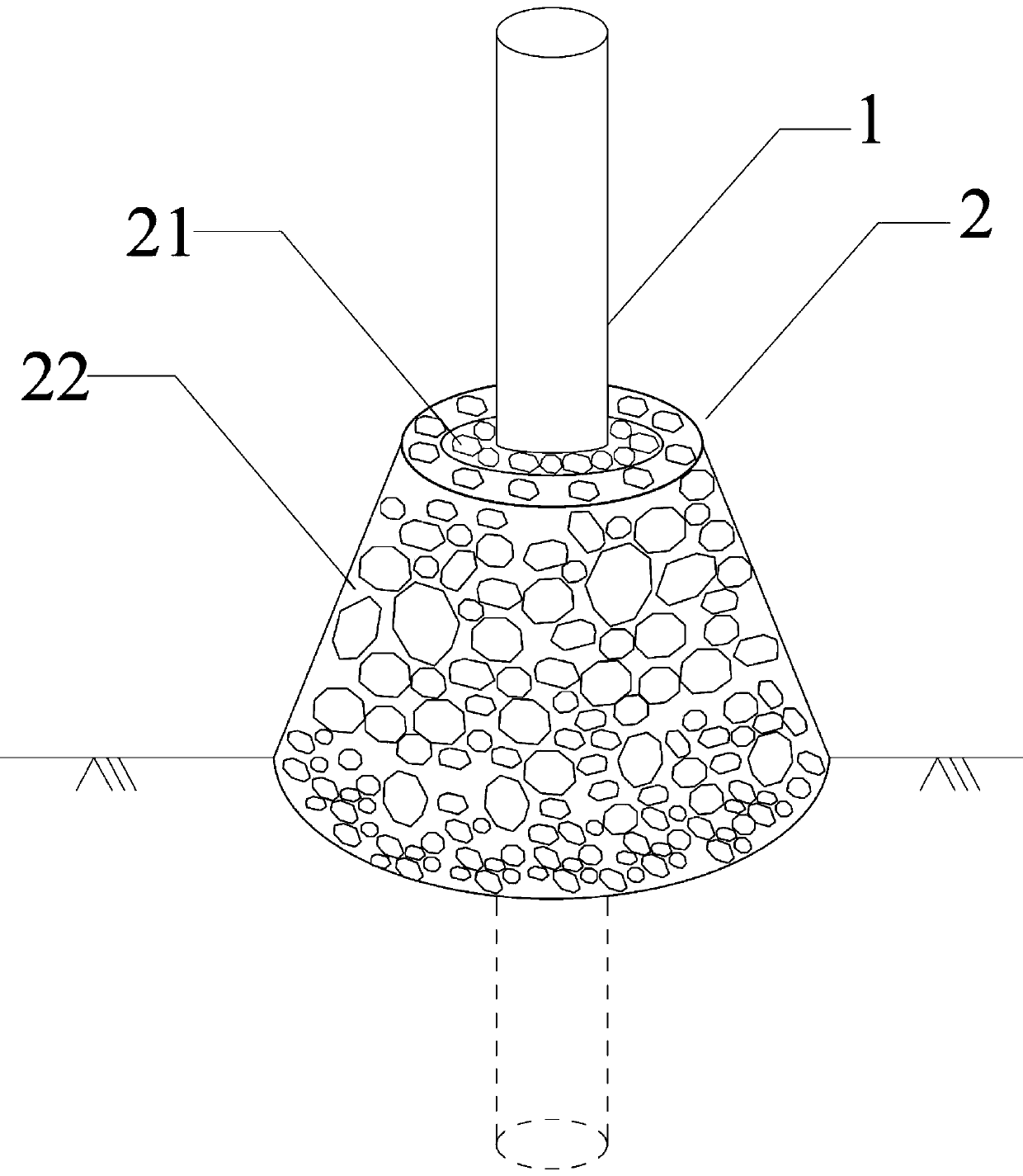

[0045] S2: Determine the accumulation range of the lower part of the friction cone 2 according to the scour range of the foundation by waves and currents, and accumulate the graded crushed stone material 4 on the seabed around the single pile by means of pipeline transportation or riprap on the construction ship, and naturally accumulate into the friction cone 2;

[0046] S3: first place the grouting device 5 on the outer surface of the friction cone 2, and then connect the grouting pipe on the grouting device 5 to the grouting machine 6 on the constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com