Rapid culture method for mixed culture denitrification desulphurization granule sludge

A technology of denitrification desulfurization and granular sludge, applied in biological sludge treatment, anaerobic digestion treatment and other directions, can solve the problem of not clearly explaining the steps and characteristics of granular sludge cultivation, and achieve good biological activity and hydraulic performance. , the removal effect is good, the effect of reducing the operating cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

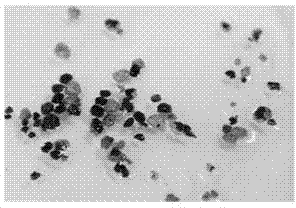

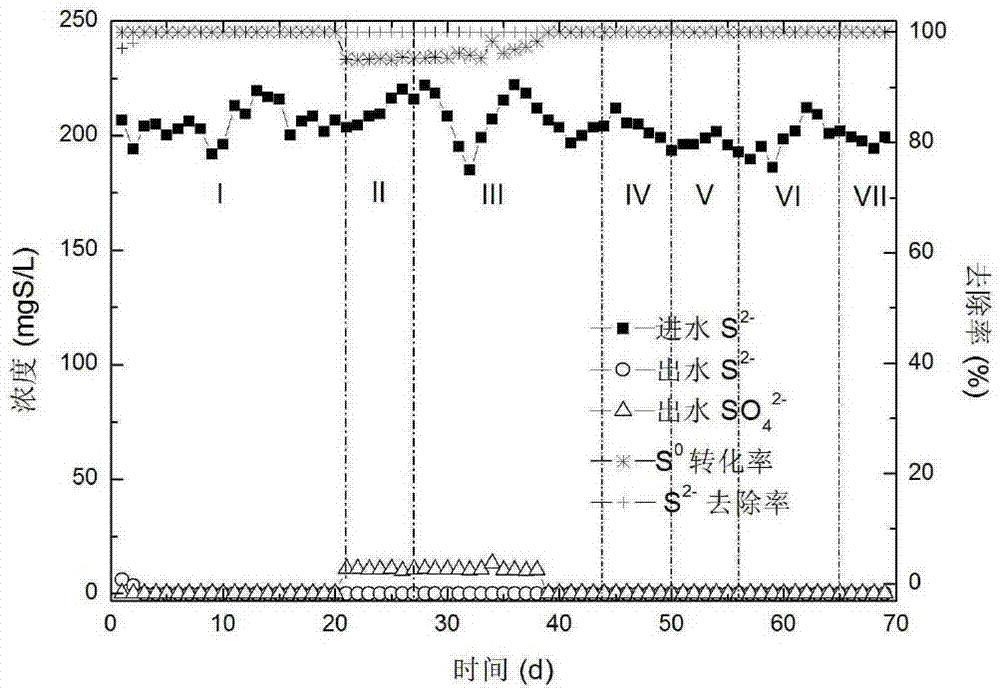

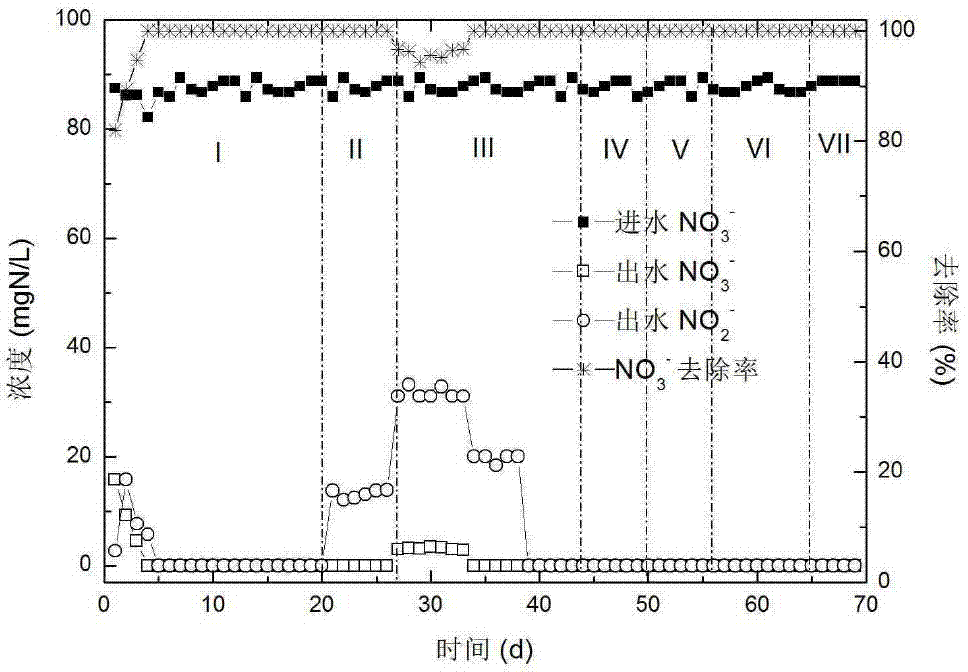

[0022] Specific embodiment one: a kind of polyculture denitrification desulfurization desulfurization granular sludge rapid cultivation method in this embodiment, realizes through the following steps: 1, take the flocculent sludge of the secondary settling tank of urban sewage plant, pack into and be equipped with three-phase separator UASB or EGSB reactor (the role of the three-phase separator is to prevent the large loss of inoculated sludge); 2. Prepare simulated wastewater containing sulfide, nitrate and organic matter, start the reactor; and add a concentration of 1 to the simulated wastewater -5g / L NaHCO 3 , to provide carbon source for the autotrophic microorganisms in the system; the molar ratio of the simulated wastewater sulfide, nitrating salt and organic matter is 1:1:1, and the pH value is 7; 3. Pump the simulated wastewater into UASB or EGSB reactor, control the temperature of the reactor at 30°C, domesticate the polyculture denitrification and desulfurization mi...

specific Embodiment approach 2

[0024] Embodiment 2: This embodiment differs from Embodiment 1 in that: the pH of the simulated wastewater in step 2 is 8. Other steps and parameters are the same as those in the first embodiment.

specific Embodiment approach 3

[0025] Embodiment 3: The difference between this embodiment and Embodiment 1 is that the pH of the simulated wastewater in step 2 is 6. Other steps and parameters are the same as those in the first embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com