Rubber composition containing hydrogenated vegetable oil, and preparation method thereof

A hydrogenated vegetable oil and rubber composition technology, which is applied in the field of polymer materials, can solve problems affecting the mechanical properties of rubber, soybean oil self-polymerization, and mechanical properties, and achieve the effect of ensuring performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

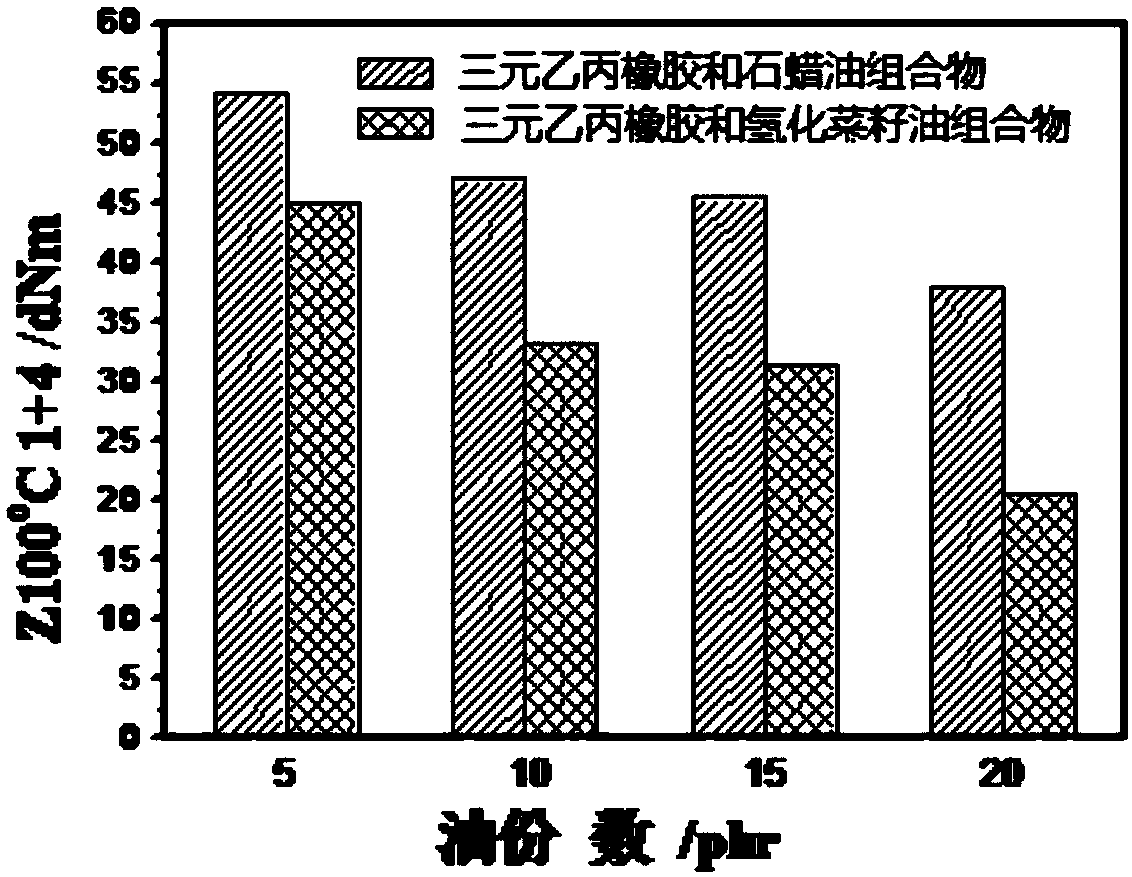

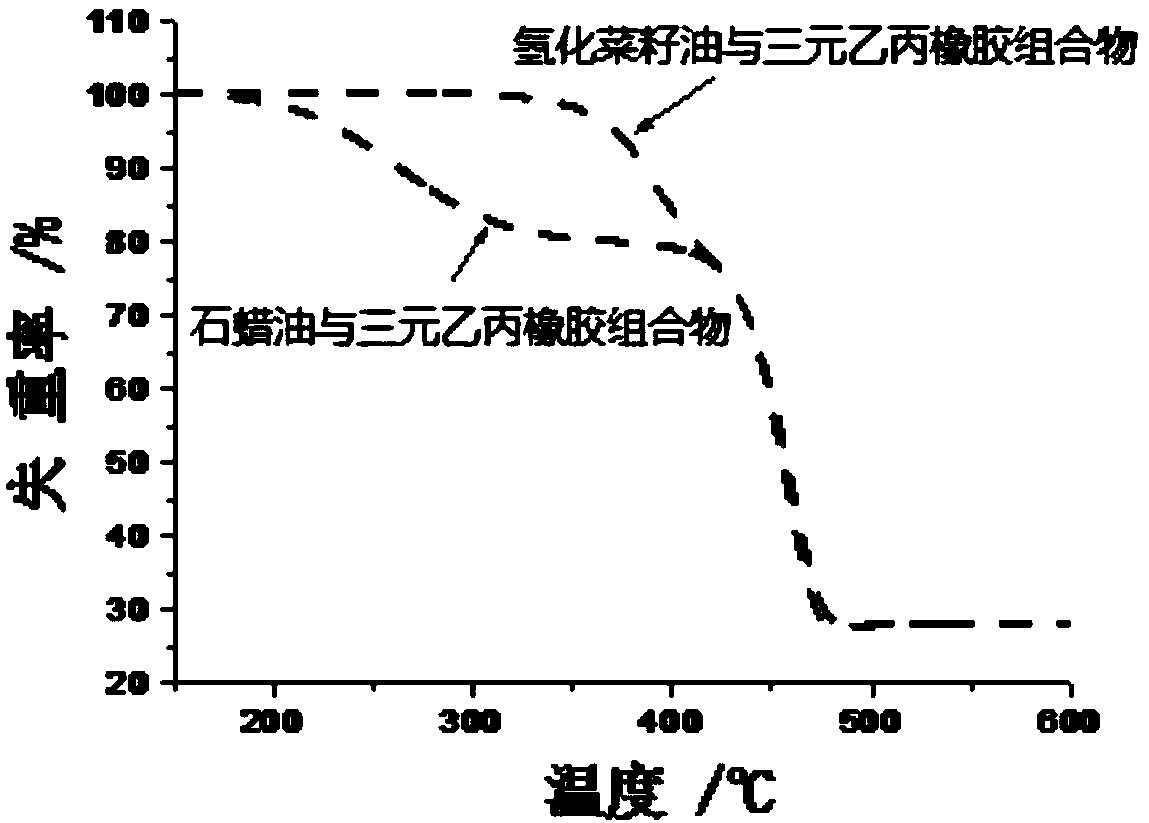

[0035] Embodiment 1: natural rubber and hydrogenated rapeseed oil composition

[0036] Add 100 g of rapeseed oil and 0.4% (oil weight) Ni catalyst into the reactor for pre-stirring, and react at 220°C and 400 r / min for 1.5 hours to obtain hydrogenated rapeseed oil with an iodine value of 30.

[0037] Add 100 parts of natural rubber (TSR20), 5 parts of hydrogenated rapeseed oil (iodine value 30), and 40 parts of white carbon black into the Haake internal mixer, mix at 80°C for 5 minutes, add 10 parts of coupling agent Si69, Then heat up to 100°C for 5 minutes, cool down to 80°C, then add 3 parts of zinc oxide, 3 parts of 4020 anti-aging agent, 2 parts of CZ accelerator, and 2 parts of sulfur into the internal mixer, mix for 5 minutes and take it out. The rubber mixture was vulcanized at 150°C for 20 minutes to obtain vulcanized natural rubber.

Embodiment 2

[0038] Embodiment 2: styrene-butadiene rubber and hydrogenated soybean oil composition

[0039] The Ni catalyst of 100g soybean oil and 3% (oil weight) is added into reactor and is pre-stirred, and reactant is uniformly mixed, reacts 8 hours under 180 ℃, 0.2MPa hydrogen pressure, 300r / min condition, obtains the iodine value 100 Hydrogenated soybean oil.

[0040] Add 100 parts of styrene-butadiene rubber (RC2564S), 20 parts of hydrogenated soybean oil (iodine value 100), and 80 parts of white carbon black into the Hack mixer, mix at 80°C for 5 minutes, add 18 parts of coupling agent Si69, Then heat up to 150°C for 2 minutes, cool down to 80°C, then add 14 parts of zinc oxide, 5 parts of 4020 anti-aging agent, 5 parts of CZ accelerator, and 9 parts of sulfur into the internal mixer, mix for 5 minutes and take it out. The rubber mixture was vulcanized at 150° C. for 15 minutes to obtain vulcanized styrene-butadiene rubber.

Embodiment 3

[0041] Embodiment 3: styrene-butadiene rubber, butadiene rubber and hydrogenated palm oil composition

[0042] 250g refined palm oil and 0.12% (oil weight) Pd-B / γ-Al 2 o 3 Put the catalyst in a reactor, and react at 100° C., 500 kPa hydrogen pressure, and 500 rpm for 1 hour to obtain hydrogenated palm oil with an iodine value of 50.

[0043] Add 70 parts of styrene-butadiene rubber (RC2564S), 30 parts of butadiene rubber (BR9000), 30 parts of hydrogenated palm oil (iodine value 50), and 60 parts of carbon black (N330) into the Haake internal mixer, and mix at 80 ° C After 5 minutes, add 7 parts of zinc oxide, 8 parts of 4020 anti-aging agent, 2 parts of CZ accelerator, and 2 parts of sulfur into the internal mixer, and take it out after mixing for 5 minutes. The rubber mixture was vulcanized at 150°C for 25 minutes to obtain vulcanized styrene-butadiene / butadiene rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com