Vehicle brake, in particular caliper brake

A caliper brake, vehicle braking technology, applied in the direction of brakes, brake types, brake components, etc., can solve problems such as strong self-locking effect and influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

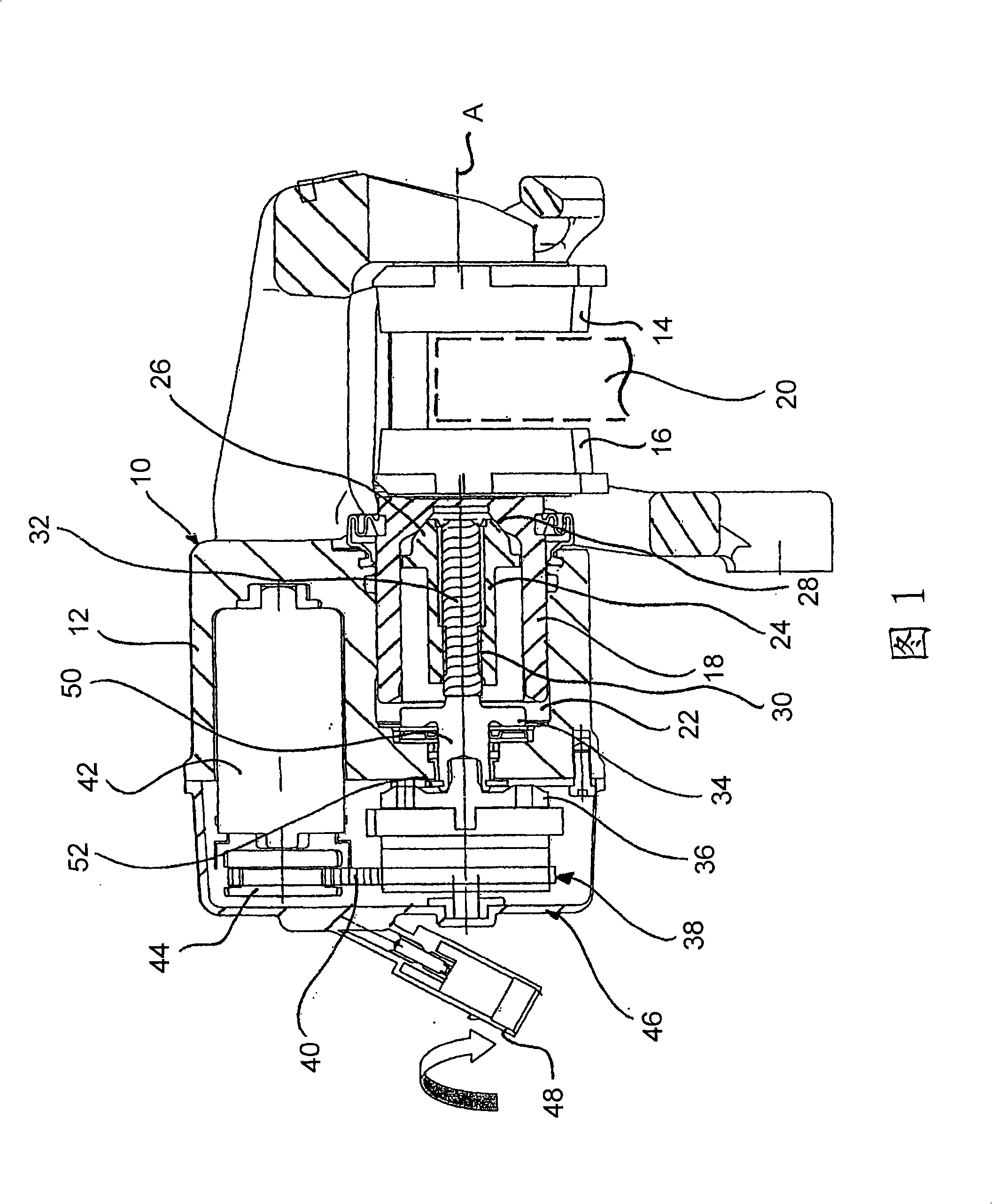

[0016] In FIG. 1 , a vehicle brake according to the invention is generally indicated by 10 . The vehicle brake 10 takes the form of a caliper brake. It comprises a housing 12 in which two brake pads 14 and 16 are accommodated on the principle of a floating caliper. The brake pads 16 are movable by the brake piston 18 along the axis A towards the brake disc 20 indicated only by dashed lines.

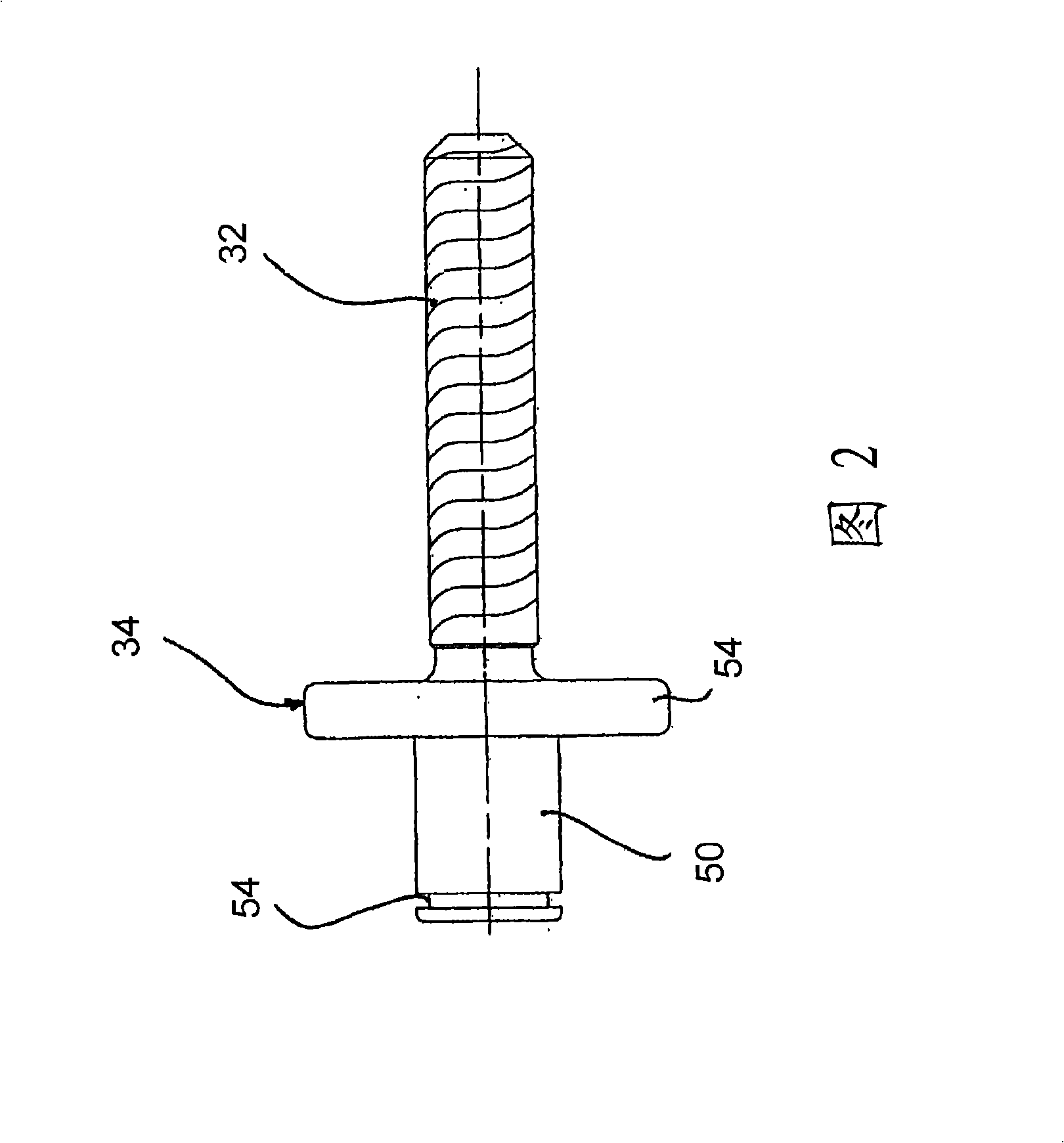

[0017] The brake piston 18 and the housing 12 enclose a hydraulic chamber 22 . The brake piston 18 is hollow in design. A nut arrangement 24 with a conical head 26 is accommodated in the brake piston 18 . The tapered head 26 can be used for locking engagement with a complementary designed tapered portion 28 inside the brake piston 18 . Furthermore, the nut arrangement 24 is accommodated in a rotationally fixed manner in the linearly displaceable brake piston 18 . The nut device 24 is likewise hollow and provided with a threaded portion 30 . A lead screw 32 is provided in the threade...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com