Steel structure beam column mortise-and-tenon-joint-type fast installing joint and installing method thereof

A steel structure, beam-column technology, applied in building structures, buildings, etc., can solve the problem of difficult construction of bolts in node areas, and achieve the effects of saving installation measures, improving buckling bearing capacity, and reasonable force transmission paths.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

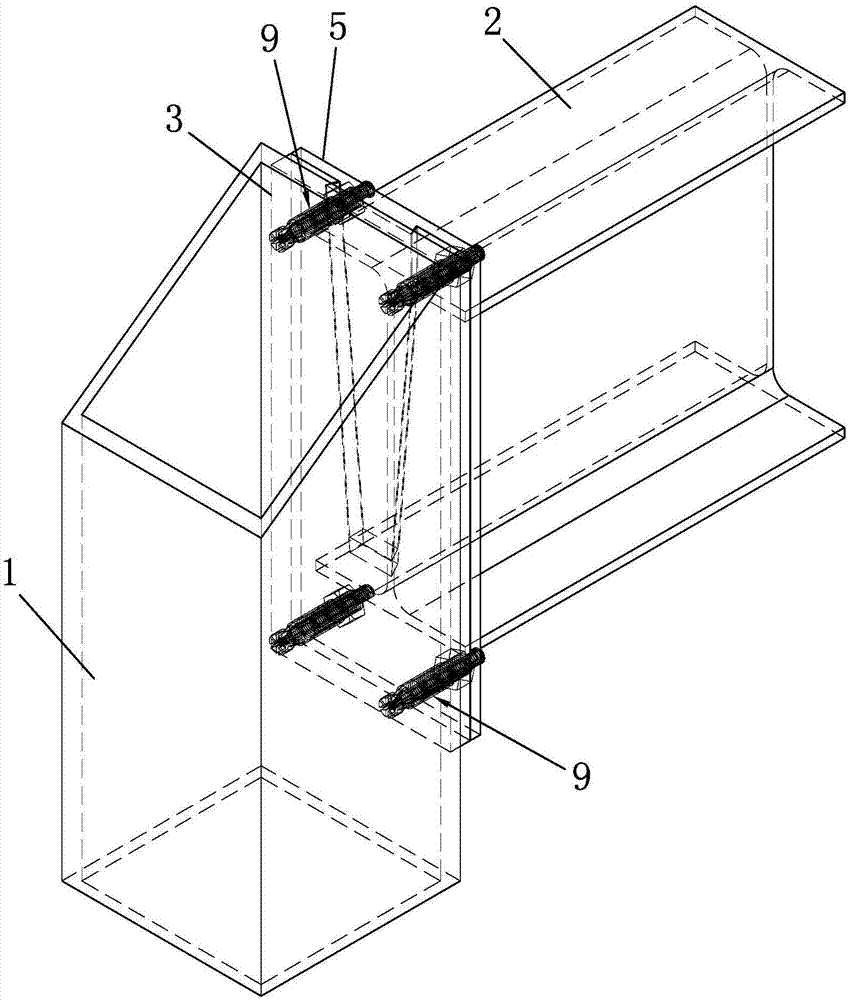

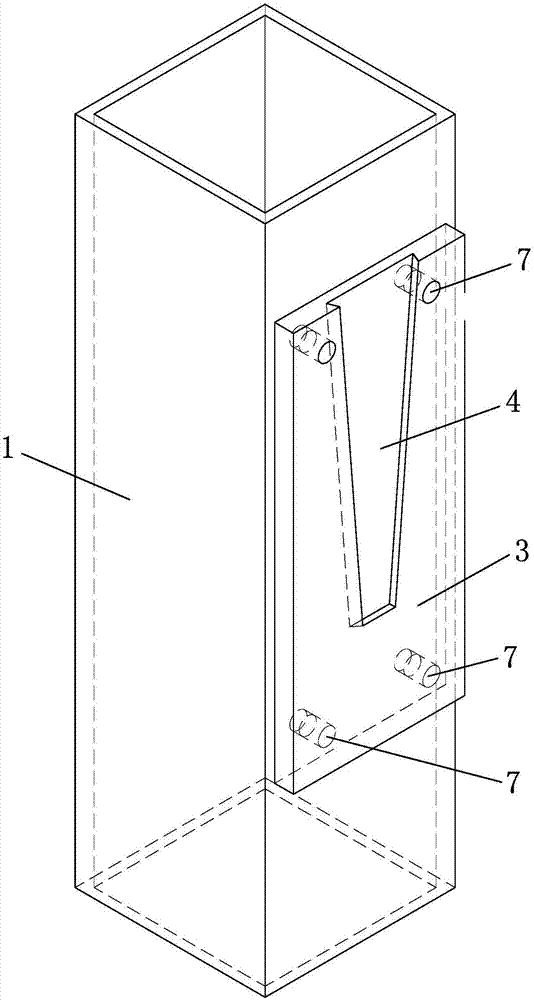

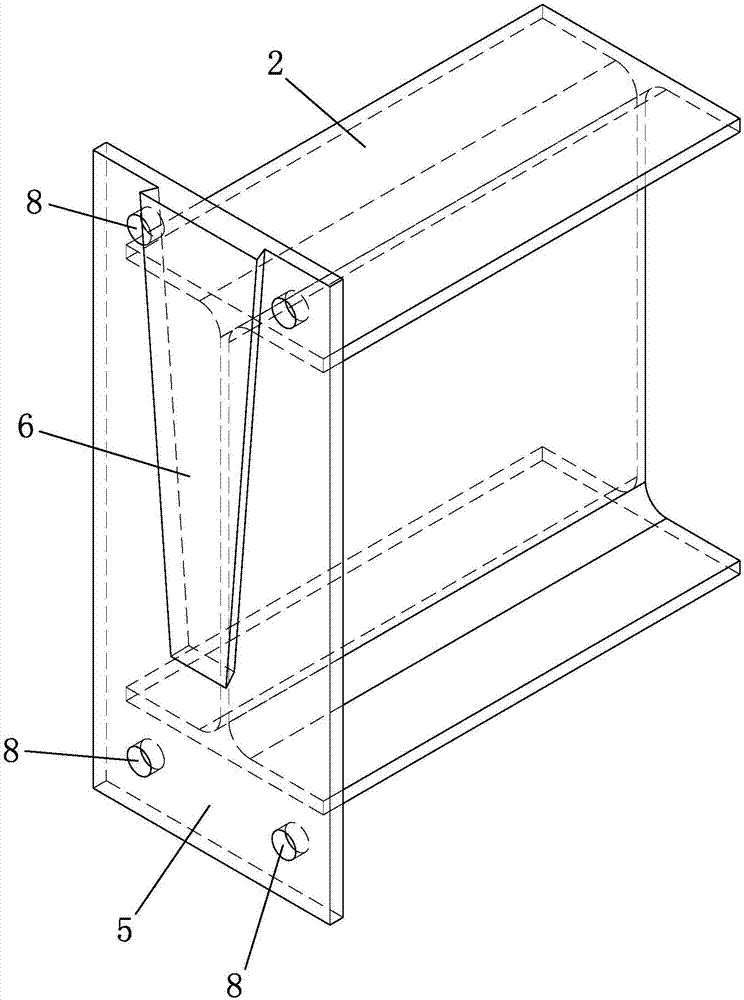

[0040] Such as Figure 1 to Figure 11 As shown, it is a steel structure beam-column mortise-and-tenon fast-installation joint in the present invention, including a steel pipe column 1 and a steel beam 2, and the steel pipe column 1 adopts one of cold-formed steel, welded steel and H-shaped steel column, which is convenient for steel pipe column 1 Use local materials to reduce costs. The steel girder 2 adopts one of H-shaped steel, I-beam, cold-formed rectangular pipe, and welded rectangular steel pipe, which is convenient for obtaining materials locally for the steel girder 2 and reduces costs.

[0041] The side of the steel pipe column 1 is welded with a reinforcement board 3 , the section width of the reinforcement board 3 is smaller than that of the steel pipe column 1 , and the reinforcement board 3 is provided with an embedding groove 4 . The end of the steel beam 2 is provided with an end plate 5 , the end plate 5 is provided with an embedded tenon 6 , the embedded teno...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com