Overline operation crane for high-speed railways

A technology for high-speed railways and cranes, applied in cranes, rescue cranes, etc., can solve the problems of increased weight of the crane itself, difficult operation and maintenance, influence and restriction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] How to implement the patent of the present invention will be further explained with the accompanying drawings:

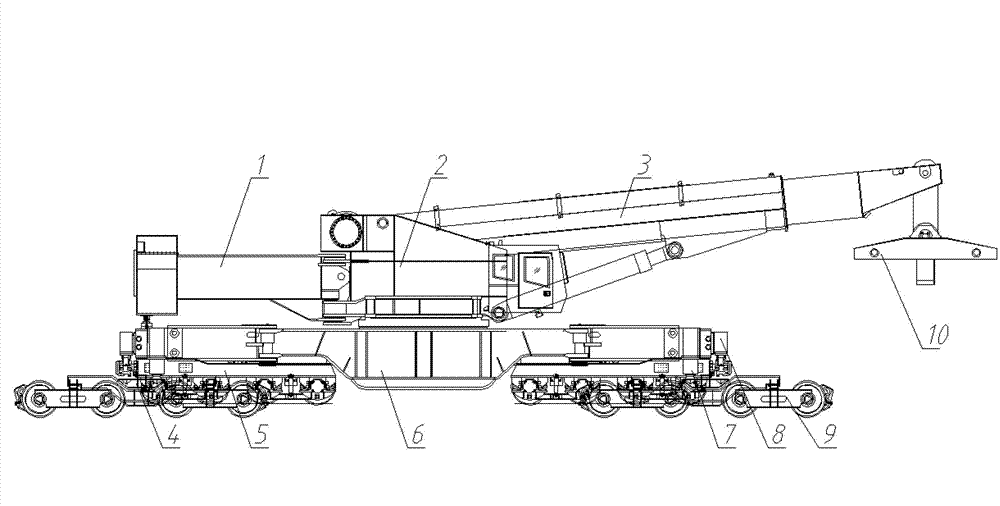

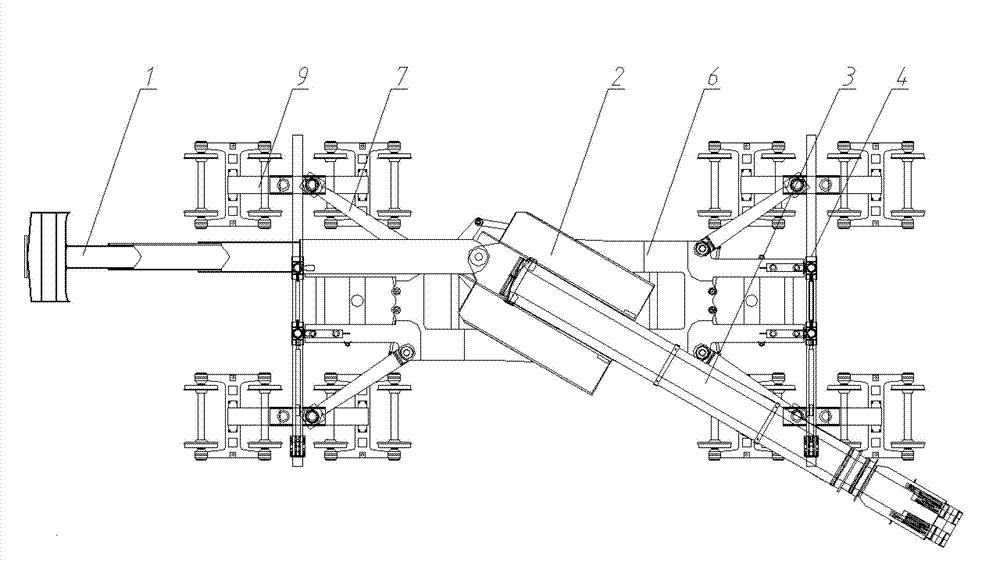

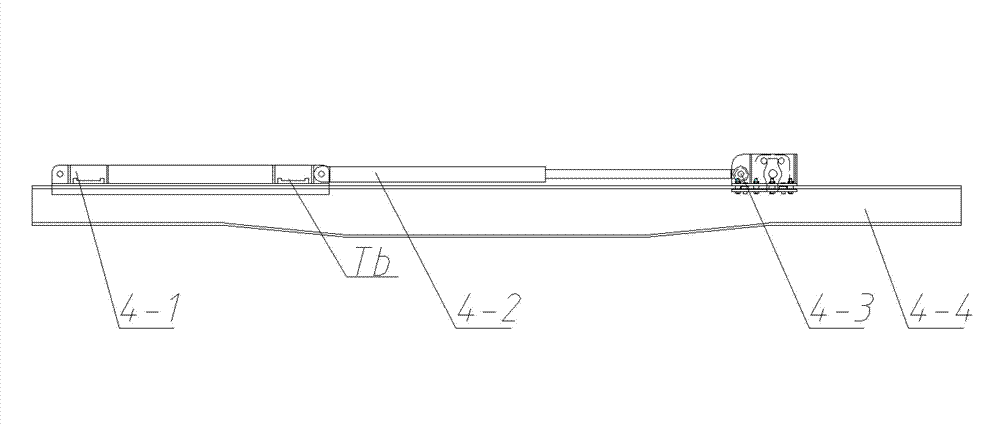

[0022] The high-speed rail crane with the patent of the invention is composed of a railway crane, a traverse mechanism 4, a special high-speed rail spreader 10, and an auxiliary supporting trolley 9. The railway crane includes an upper car and a lower car. The upper car includes a turntable 2, a telescopic boom 3, a slewing mechanism, and a telescopic counterweight 1. The lower car includes a chassis 6, a crane leg 7, a bogie 5, and an auxiliary leg 8. The lower end of the jacking cylinder in the crane leg 7 is a ball head with a spherical hinge structure, which can be matched with the spherical hinge seat on the longitudinal beam of the supporting trolley 9. The hook of the telescopic boom 3 of the crane can be embedded in the web of the upper beam of the special high-speed rail spreader 10, and is connected with the spreader by two pin shafts crossing the web....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com