Pesticide thiodicarb wastewater pretreatment system and method

A dimethedocarb, pretreatment technology, applied in water/sewage multi-stage treatment, degassed water/sewage treatment, oxidized water/sewage treatment, etc., can solve the problem of poor biodegradability, large amount of waste residue and immature Effective industrialization treatment methods and other issues to achieve the effect of improving biodegradability and reducing load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

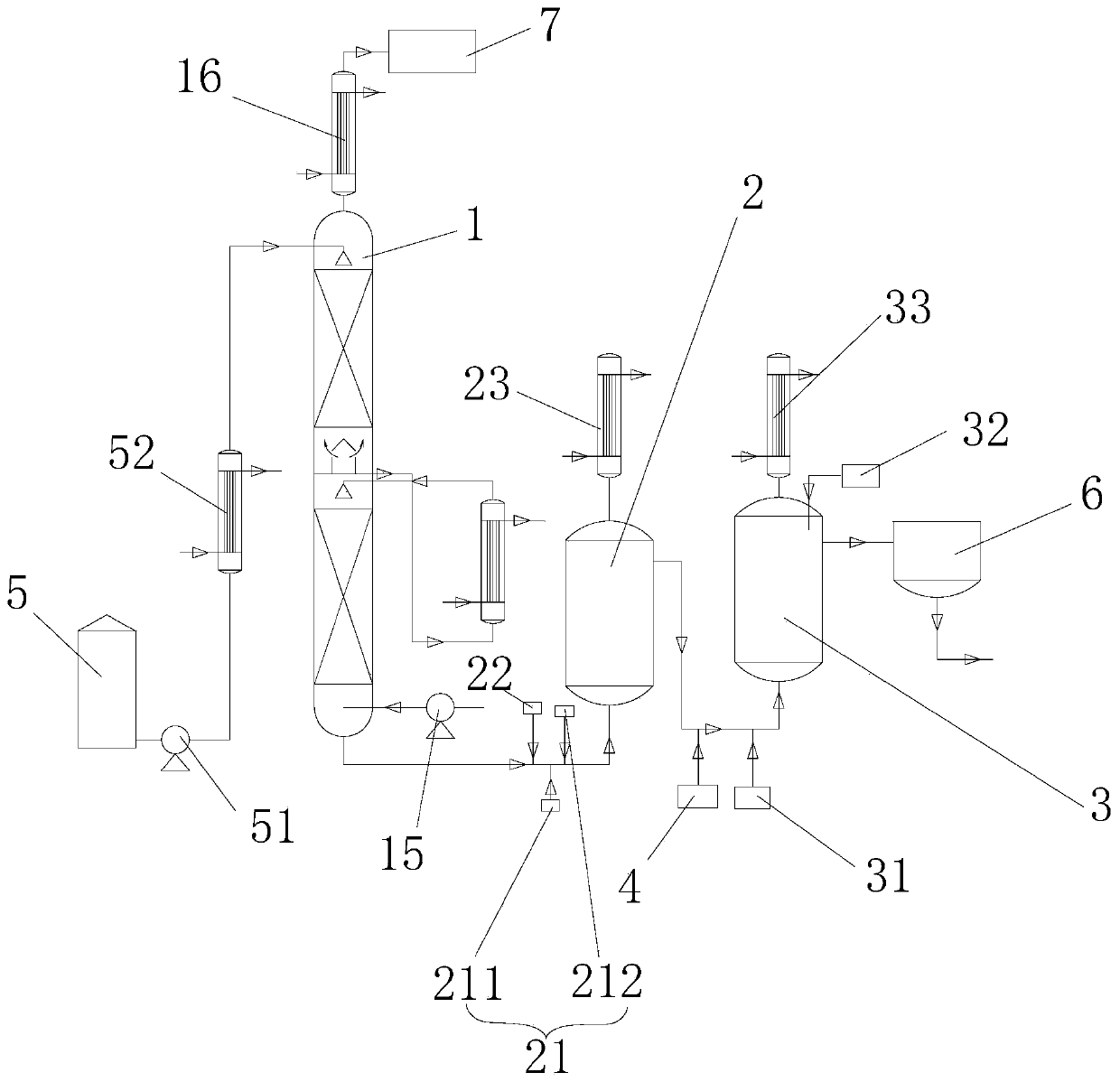

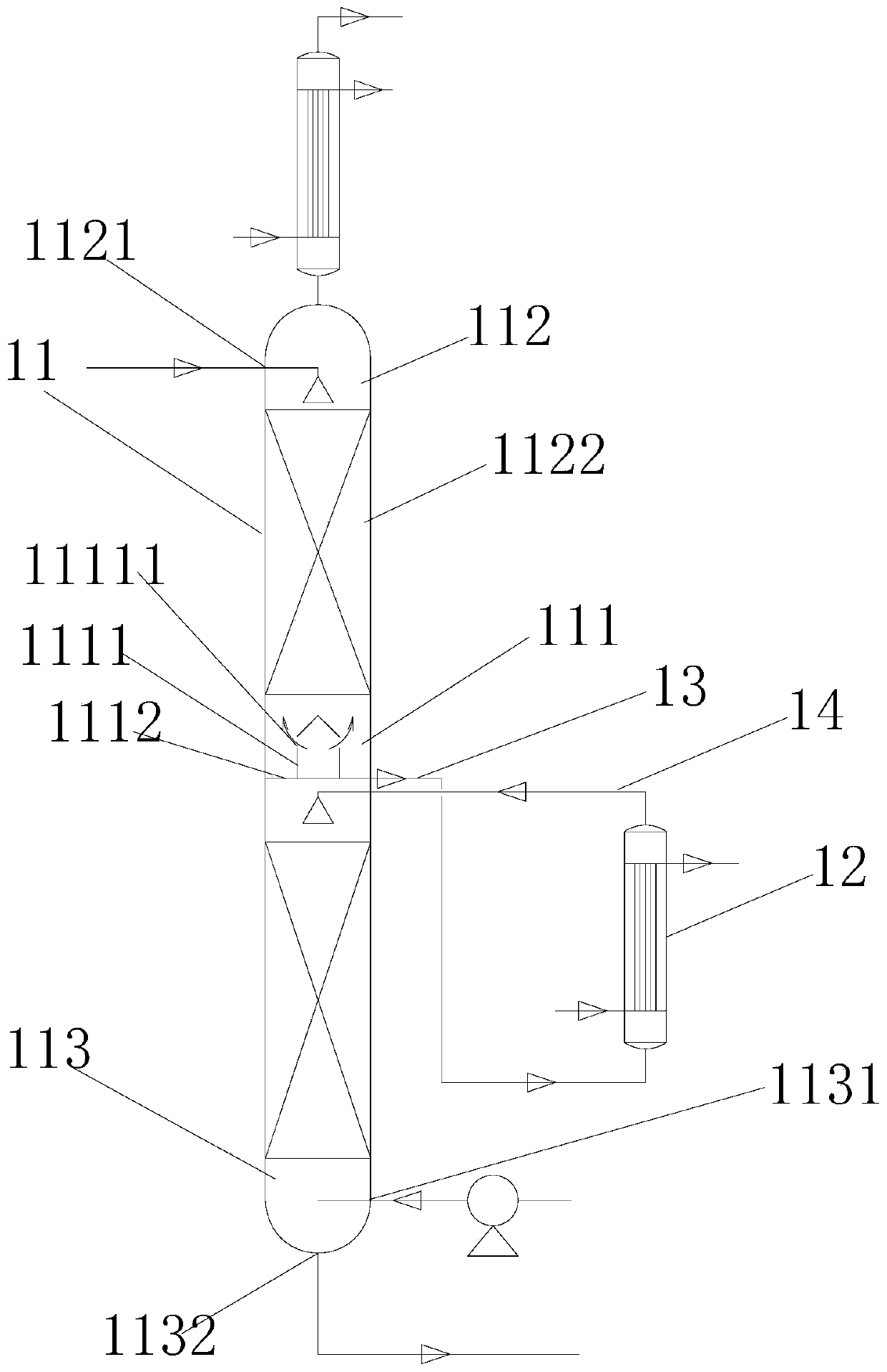

[0036] Such as figure 1 and figure 2 As shown, the thiodimethomyl production wastewater pretreatment system of the present embodiment includes a heating stripping tower 1, a heating Fenton kettle 2 and a neutralization flocculation kettle 3 connected successively through pipelines, and the heating stripping tower 1 is used for Remove the pyridine in the pesticide thiodicarb wastewater to obtain the wastewater after removing the pyridine; the heating Fenton kettle 2 is used to remove the organic pollutants in the wastewater after removing the pyridine; the heating and stripping tower 1 includes a tower body 11 and Heater 12, the tower body 11 is provided with a hollow chamber 111, the hollow chamber 111 separates the tower body 11 into an upper tower body 112 and a lower tower body 113, the upper tower body 112 is provided with a water inlet 1121, and the lower tower body 113 is provided with an inlet The air port 1131; the hollow chamber 111 communicates with the upper tower...

Embodiment 2

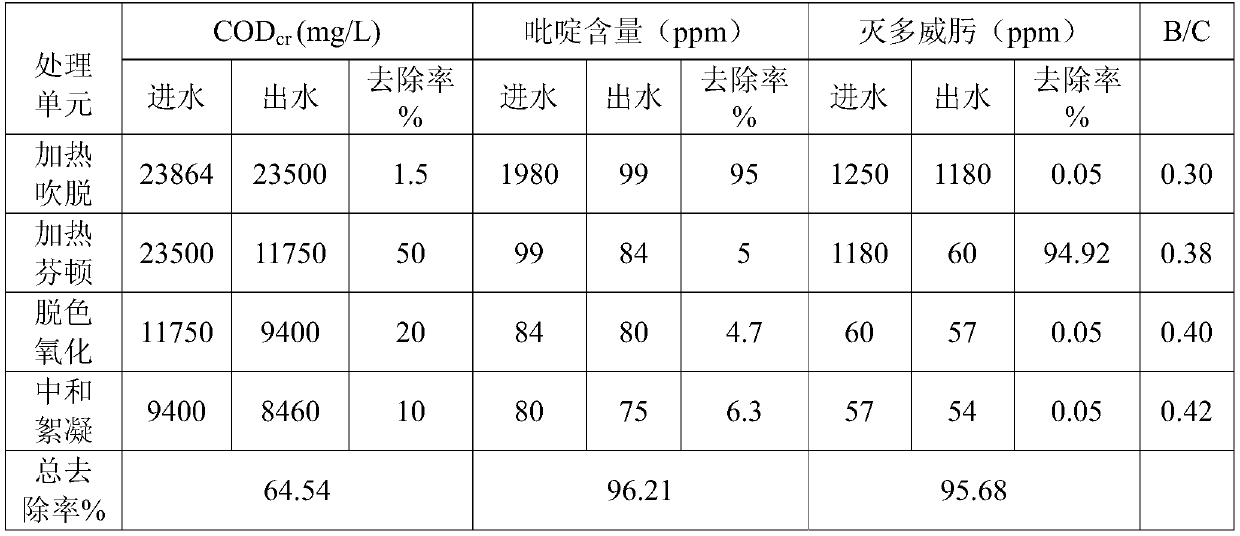

[0063] A kind of thiodimethomyl production wastewater pretreatment system of embodiment 2 is used for the pretreatment method of thiodicarb production wastewater, and thiodicarb wastewater comes from a certain pesticide company in Jiangxi, comprising the following steps:

[0064] 1) Heating and stripping: the waste water from the waste water tank 5 is heated to 60°C by the waste water heater 52 and pressurized by the booster pump 51, and enters the upper tower body 112 from the water inlet 1121 at a flow rate of 4500 kg / h Inside, after the air is accelerated by the blower 15, the ventilation flow rate is 409.09m 3The speed of / h is blown into the lower tower body 113 from the air inlet 1131, and the volume ratio of the air to the heated dimethomyl production wastewater is 100:1. The thiodimethomyl wastewater enters the hollow chamber 111 after passing through the packing area 1122, and when the water level of the hollow chamber 111 exceeds the height of the overflow pipe 13, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com