Integral disassembly box girder internal mold and use method thereof

A mold and box girder technology, applied in bridges, bridge construction, bridge parts, etc., can solve problems affecting quality, small quality defects, inconvenient connection of self-demolition internal molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Below we combine the accompanying drawings and specific embodiments to further describe the box girder inner mold and the method of use of the present invention in order to understand its structural composition and use more clearly, but not in terms of This limits the protection scope of the present invention.

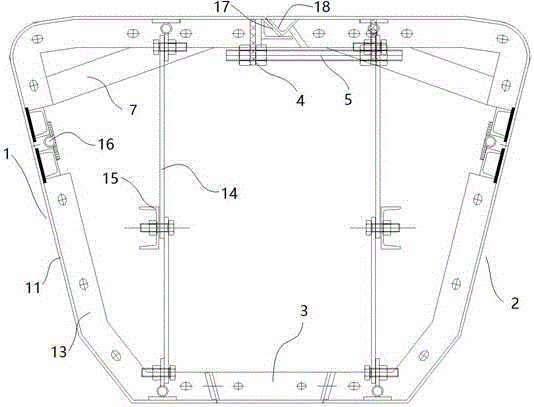

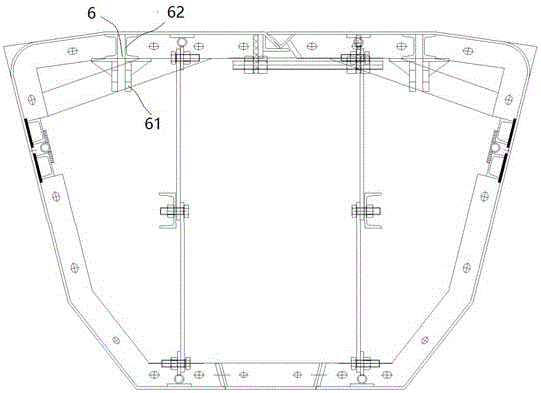

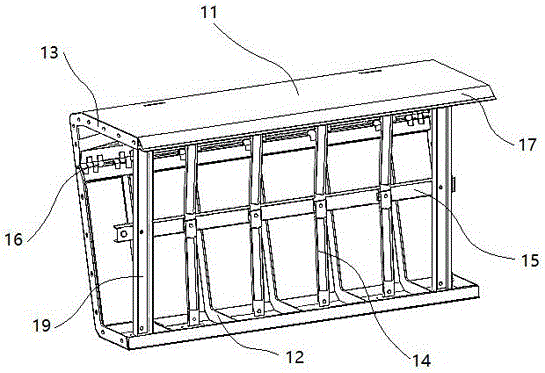

[0033] The present invention relates to a box girder internal mold that can be fully disassembled from a living body. The interior of the box girder is a box cavity with an inverted trapezoidal cross section. The internal mold includes a support end mold and a mid-span mold. The support end molds are arranged at the ends of both ends of the box girder, and the mid-span mold is arranged at the middle of the box girder.

[0034] Such as figure 1 As shown, the support end mold includes a support left half mold 1, a support right half mold 2 and a lower patch plate 3. The left half mold 1 of the support includes a panel 11 , a rib plate 12 , a flange plate 13 , a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com