Upper structure of hollow board beam bridge and construction method thereof

A hollow plate and hollow technology, applied in the direction of bridges, bridge parts, bridge materials, etc., can solve the problems of single plate stress damage, hinge joint damage, etc., to achieve the effect of ensuring service life, reducing stress, and improving overall rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the drawings and embodiments.

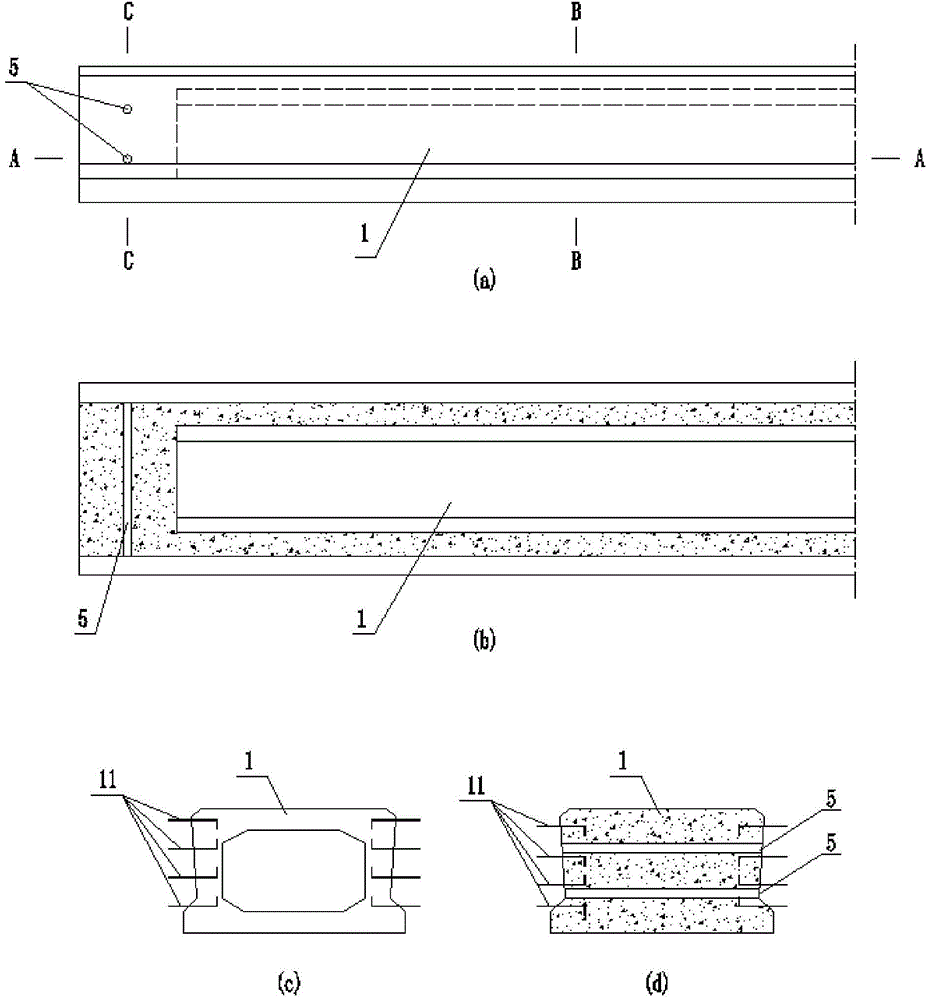

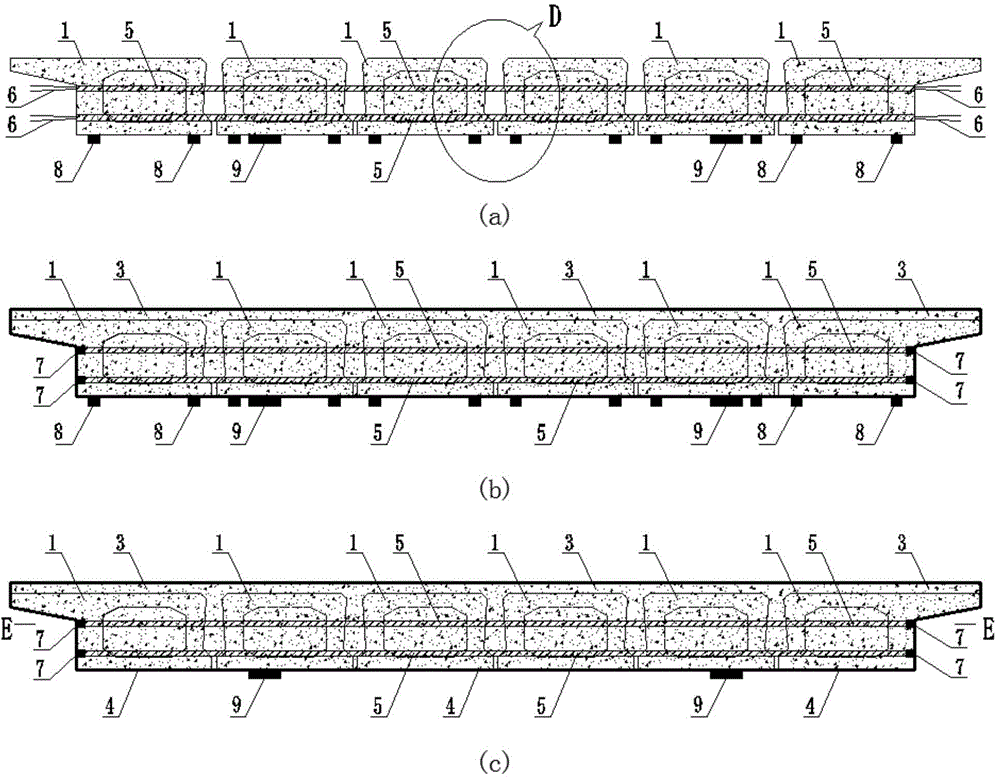

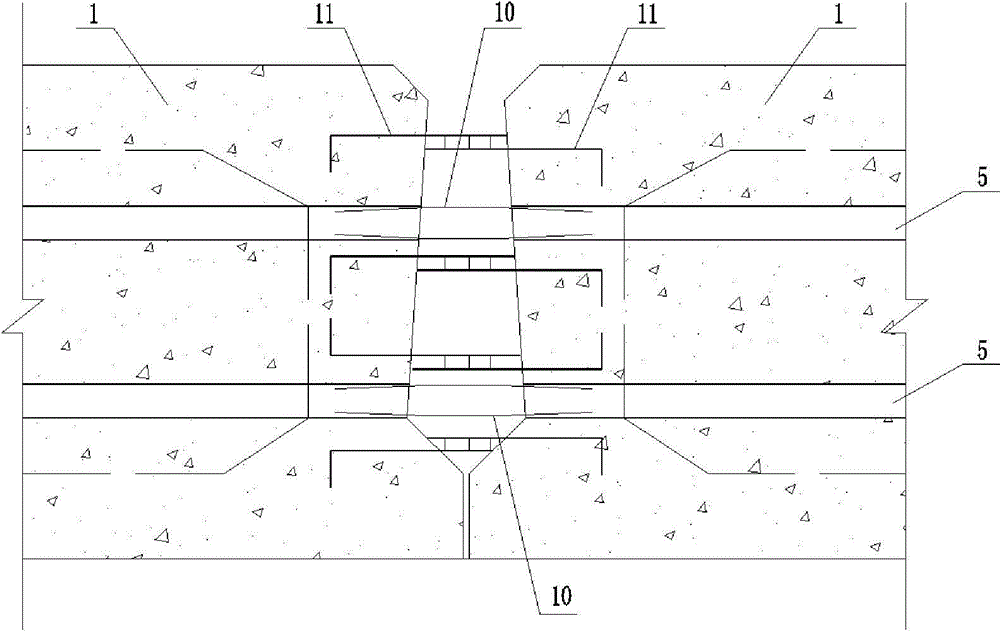

[0034] In the upper structure of the hollow slab girder bridge given in this embodiment, the hollow slab girder is composed of 6 hollow slabs 1. The hollow slab is poured with C50 concrete, and its length, width and height are (1296╳124╳75)cm. The middle part of the hollow slab 1 is hollow, and the two ends are solid bodies. The length of the solid body in the longitudinal direction of the hollow slab is 75cm. Use C50 concrete. The hollow slabs are prefabricated in the factory with templates. During prefabrication, the prestressed pipe 5 adopts a plastic corrugated pipe with an inner diameter of 8cm, and two are embedded horizontally in the solid bodies at both ends of the hollow slab, and transverse steel bars 11 with a length of 10cm are pre-embedded on both sides of the hollow slab. The diameter is 16mm.

[0035] When constructing on site, first arrange temporary s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com