Patents

Literature

48results about How to "Not easily damaged" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

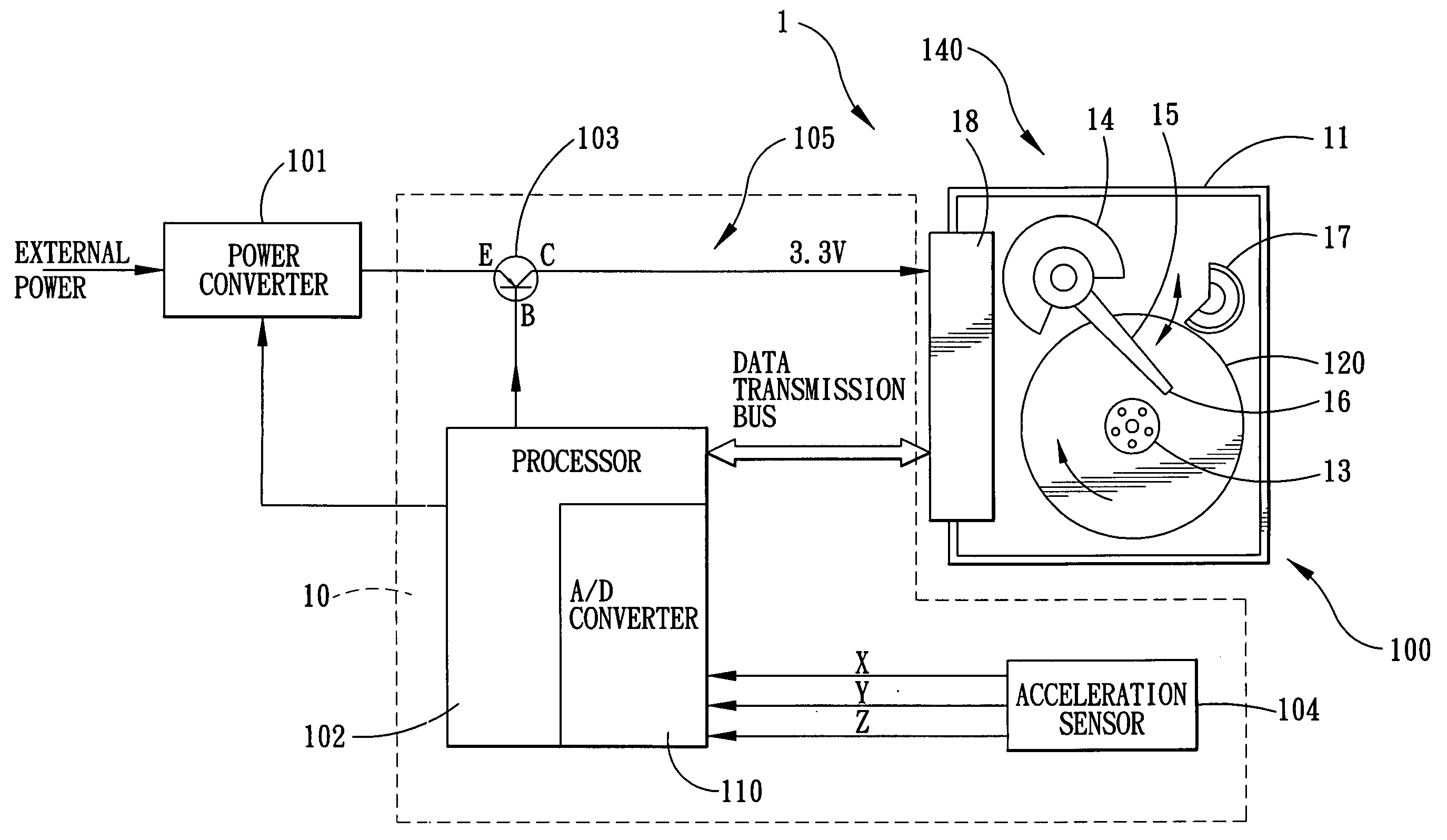

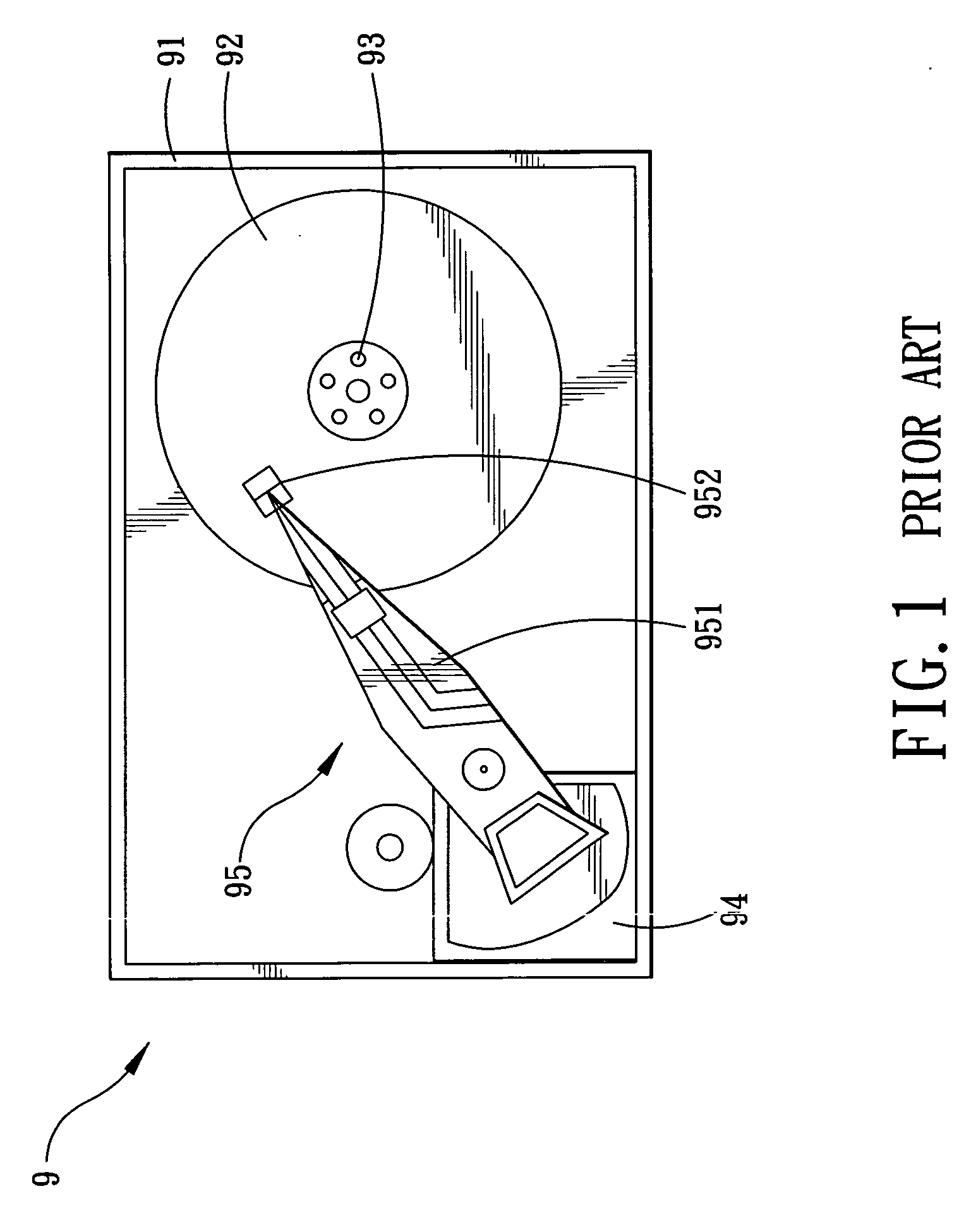

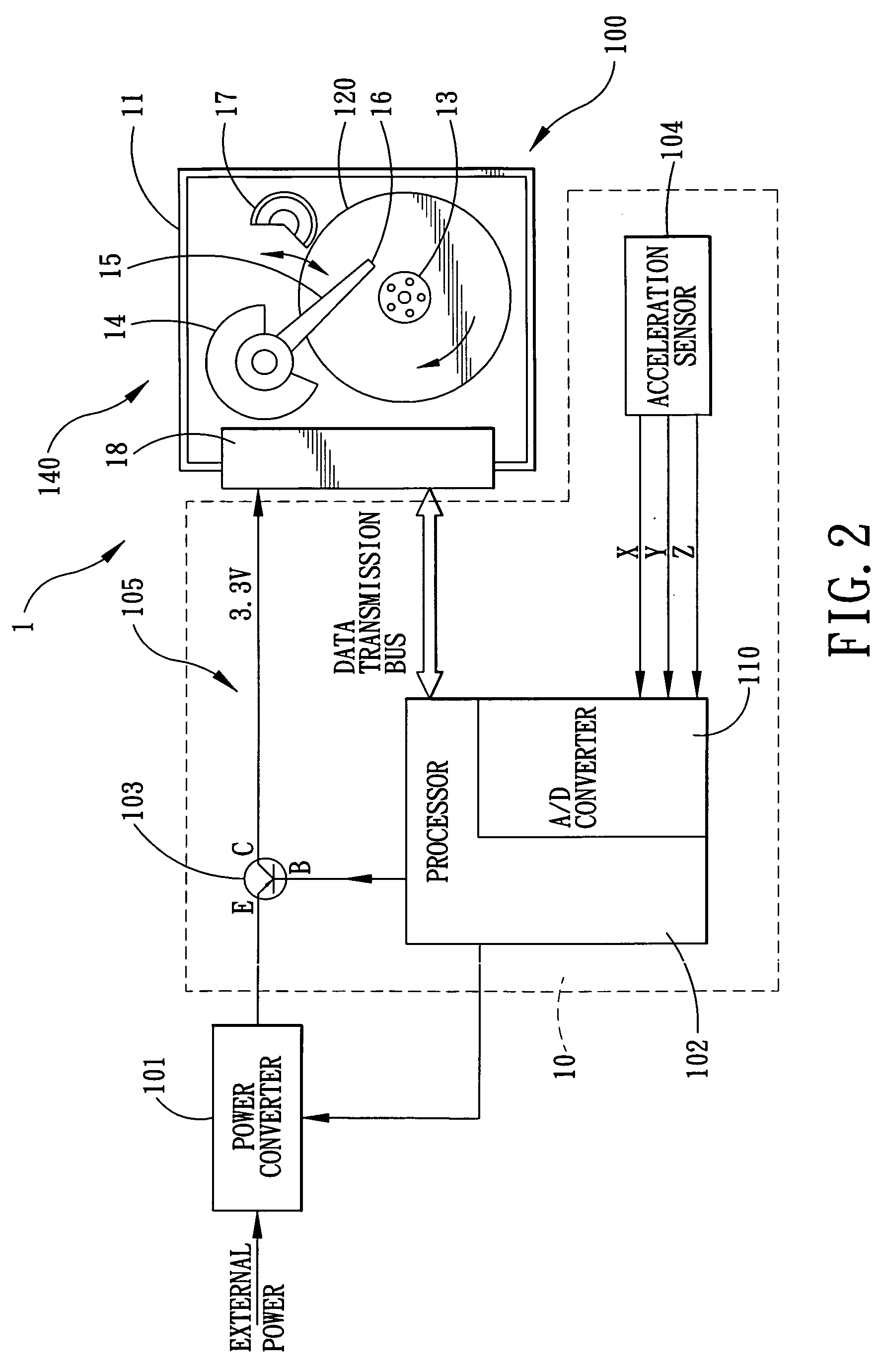

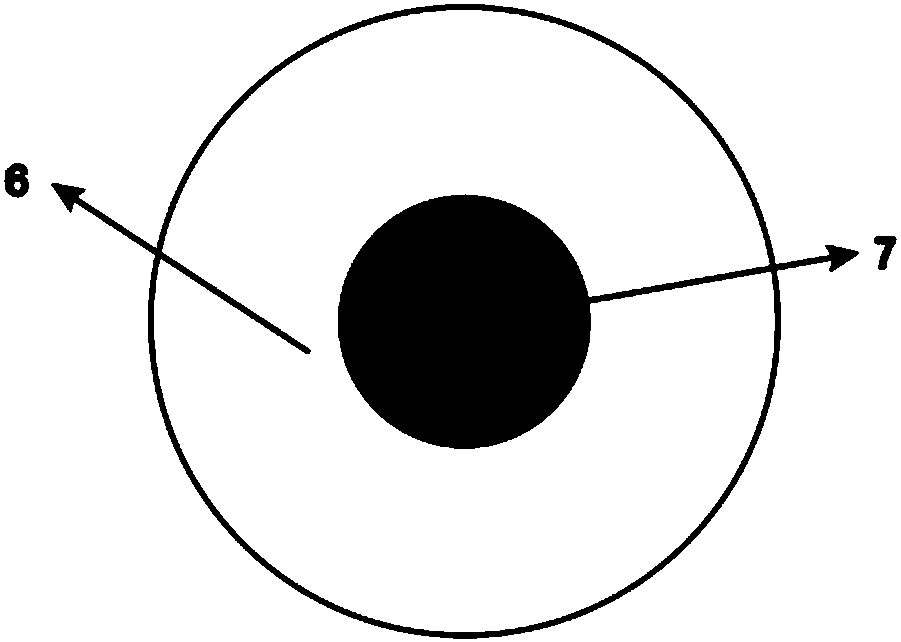

Shock-resistant magnetic storage medium for a portable electronic device

InactiveUS20060215299A1Not easily damagedNot easy to damageDriving/moving recording headsFilamentary/web record carriersMagnetic disksCircuit protection

A shock-resistant magnetic storage medium includes a circuit protection module coupled between a power converter and a magnetic disk assembly. The circuit protection module includes an acceleration sensor for generating output signals that indicate a falling state of the magnetic disk assembly, a switch operable so as to make or break a circuit connection between the power converter and the magnetic disk assembly, and a processor for controlling the switch to break the circuit connection between the power converter and the magnetic disk assembly based on the output signals from the acceleration sensor so as to interrupt supply of electric power to the magnetic disk assembly when the magnetic disk assembly is dropped.

Owner:MATSUSHITA ELECTRIC (TAIWAN) CO LTD

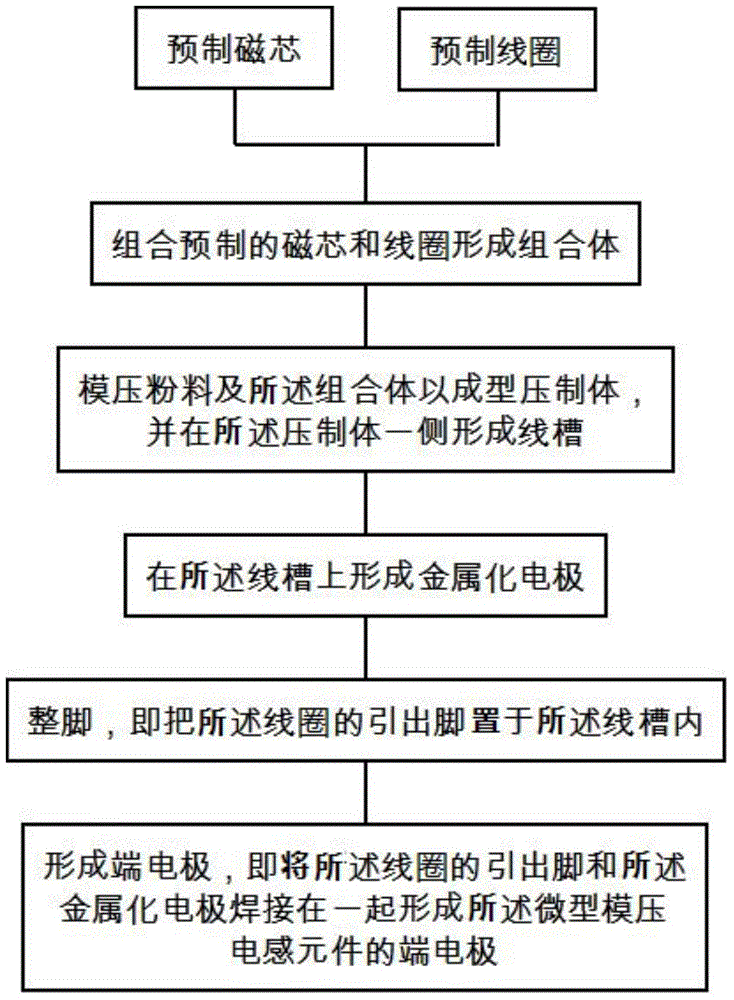

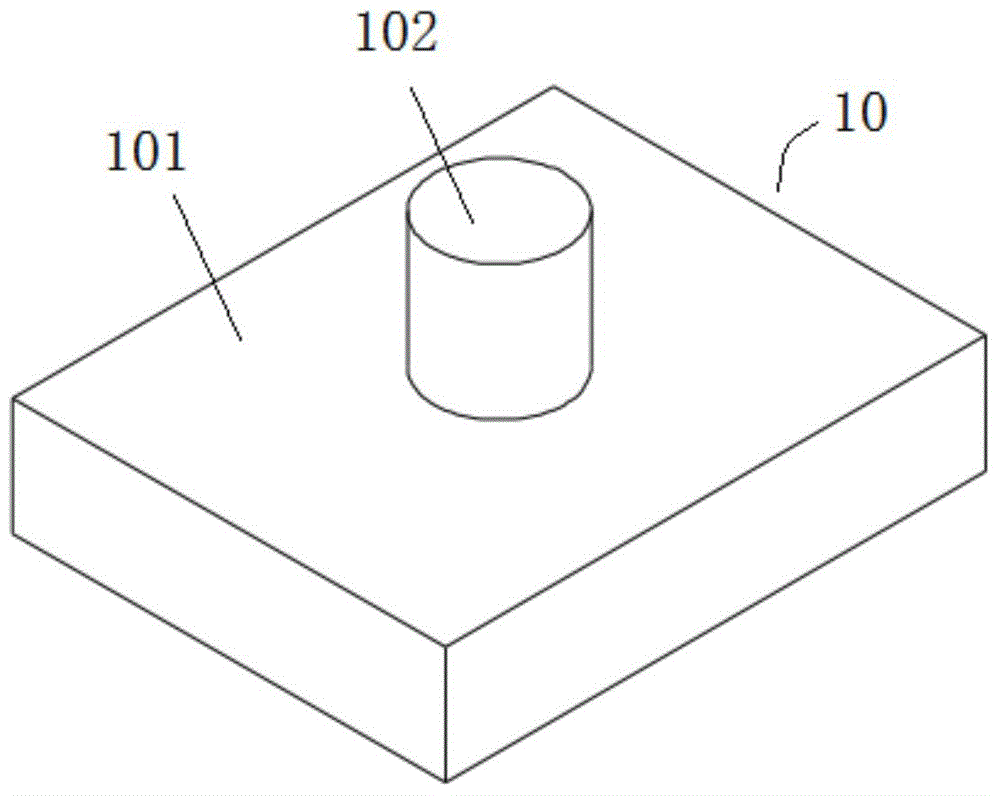

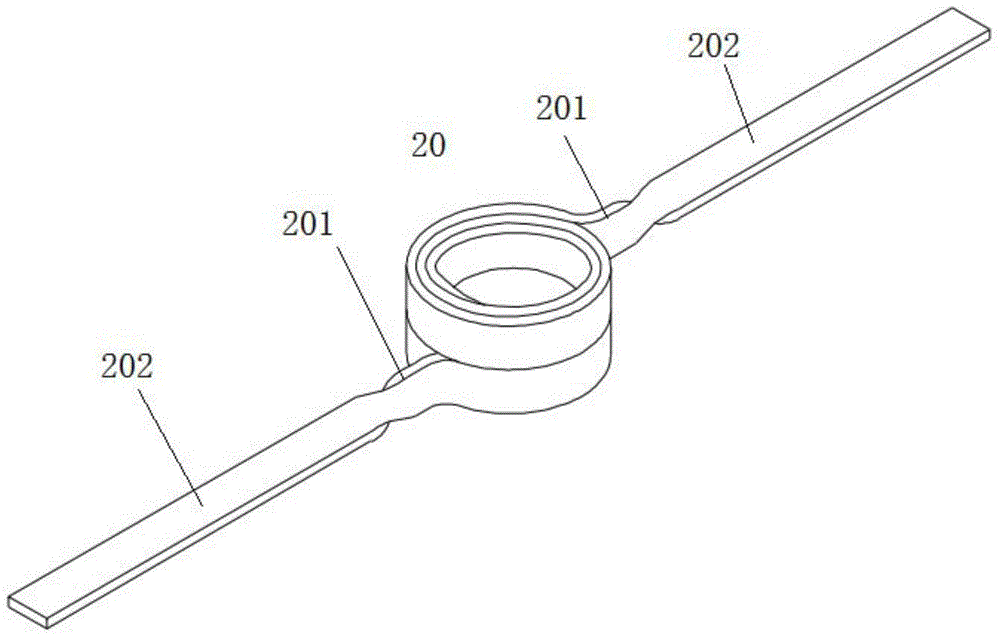

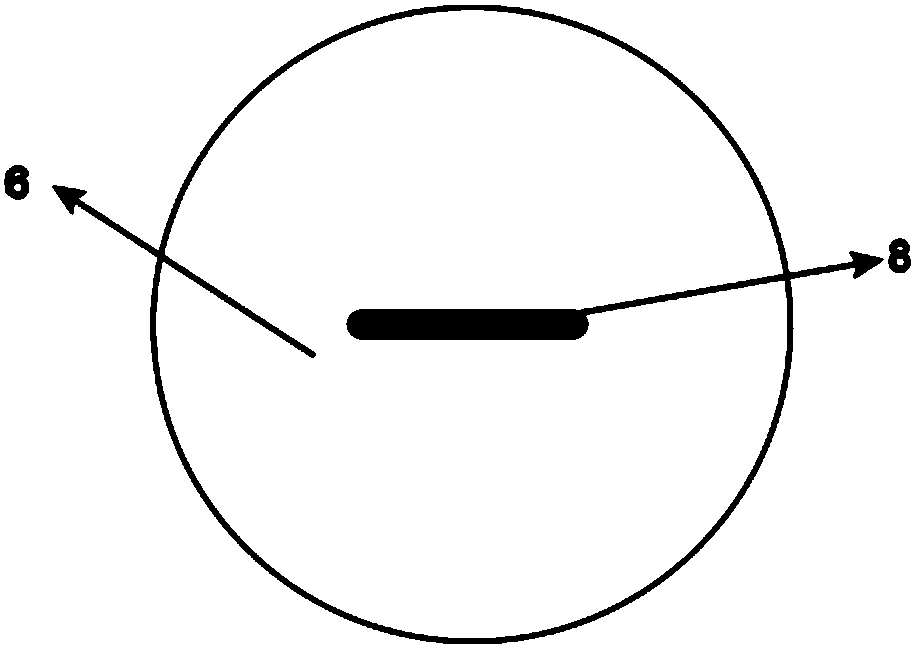

Miniature compression molding inductance element and manufacturing method thereof

ActiveCN104616878AGood consistencyNot easily damagedTransformers/inductances coils/windings/connectionsCoils manufactureMagnetic coreInductor

The invention discloses a miniature compression molding inductance element and a manufacturing method thereof. The manufacturing method of the miniature compression molding inductance element comprises the steps that a magnetic core and a coil are prefabricated; the prefabricated magnetic core and coil are combined into a combined body; powder and the combined body are compressed and molded to form a compression body, and a wire slot is formed in one side of the compression body; a metal electrode is formed on the wire slot; pin arrangement is carried out, in other words, the leading-out pin of the coil is arranged in the wire slot; an end electrode is formed, in other words, the leading-out pin of the coil and the metal electrode are welded together to form the end electrode of the miniature compression molding inductance element. By means of the manufacturing method of the miniature compression molding inductance element, the manufactured inductance element has the better consistency and is not likely to be damaged in the machining process, and the product reliability is higher. In addition, by means of the coil prefabrication technology, product machining is more flexible, the problem that a magnetic core is cracked in the prior art is avoided, and therefore the manufacturing method is more applicable to achieving volume production of thin and miniature power inductance elements.

Owner:东莞华络电子有限公司

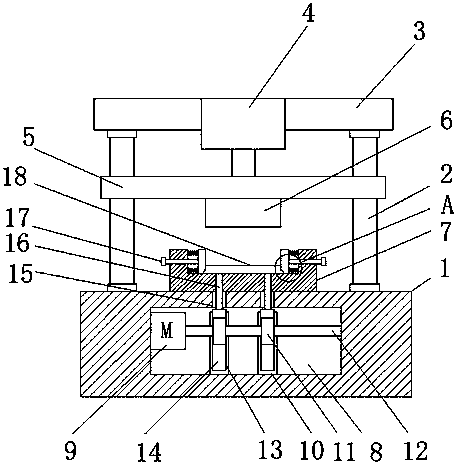

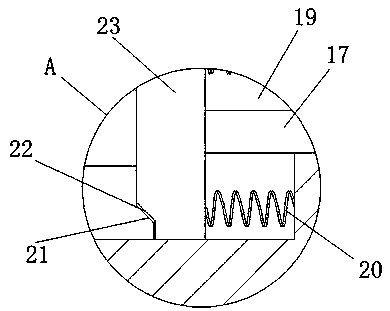

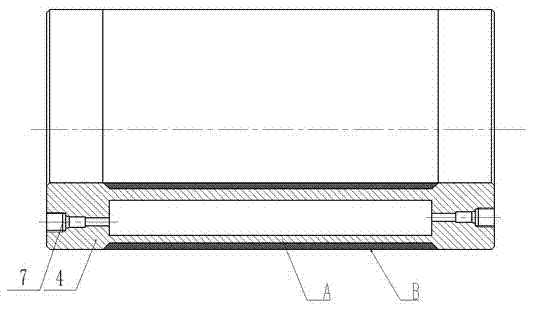

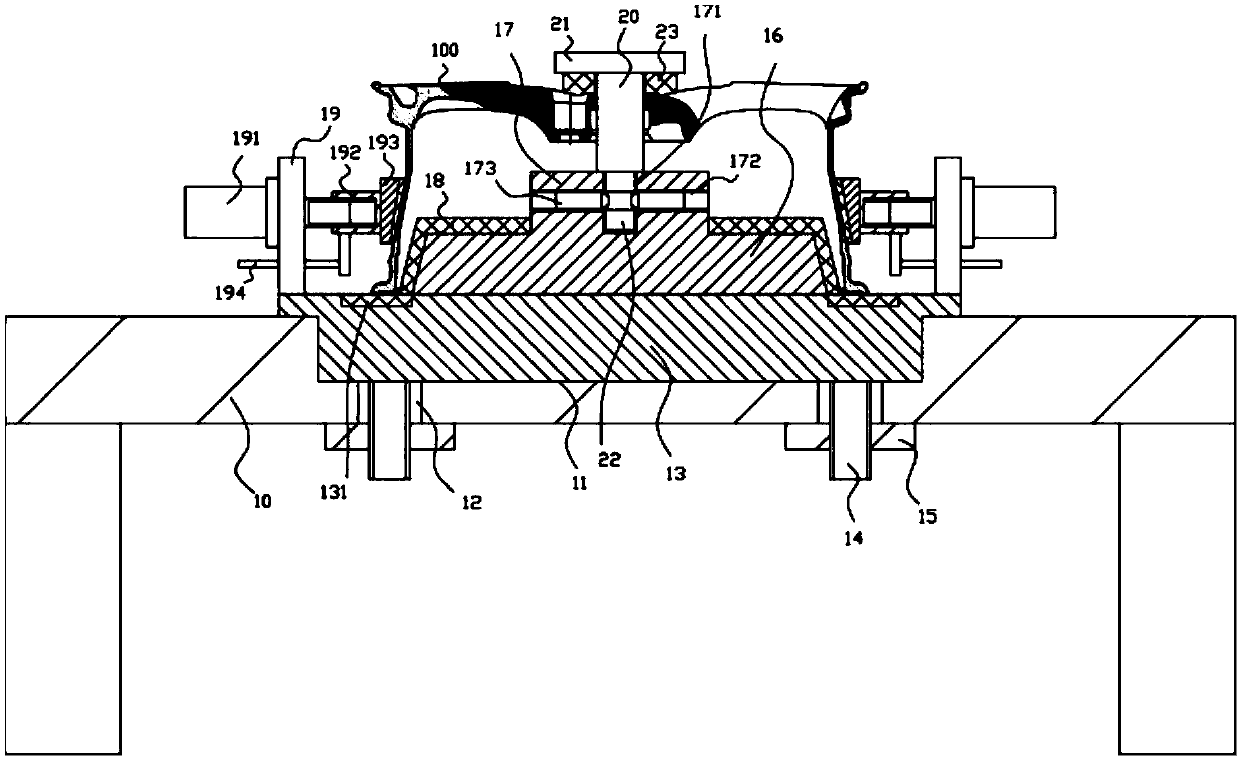

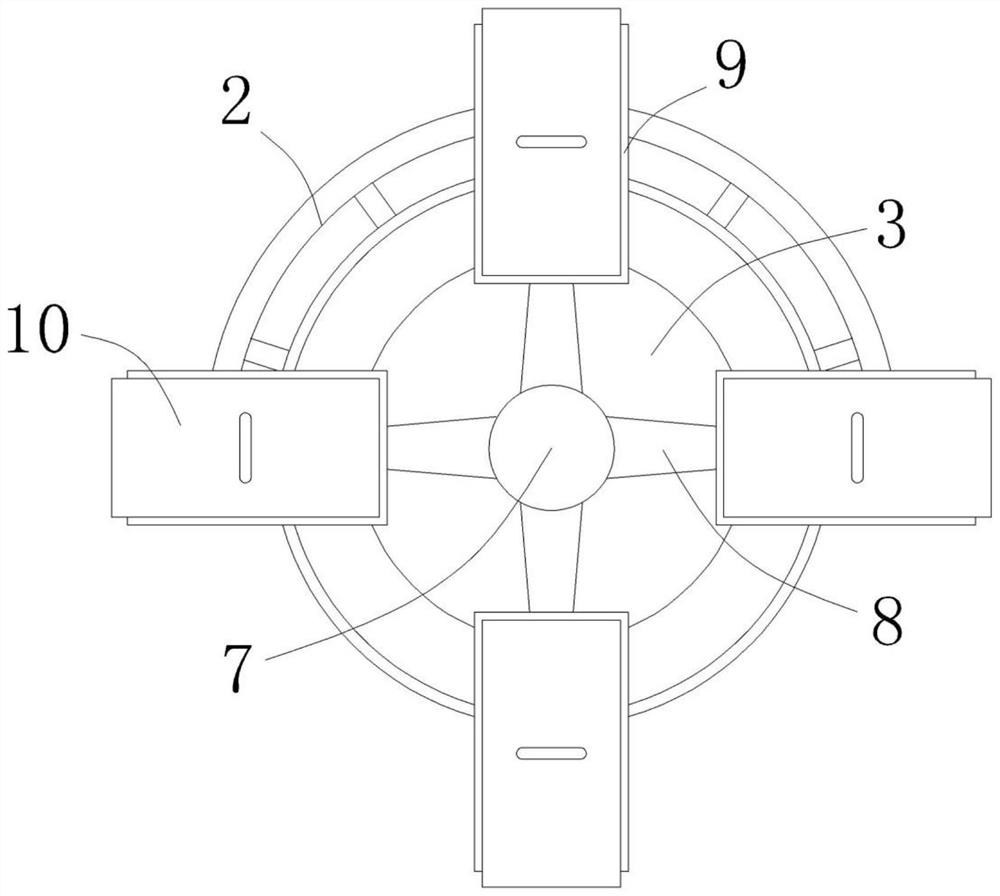

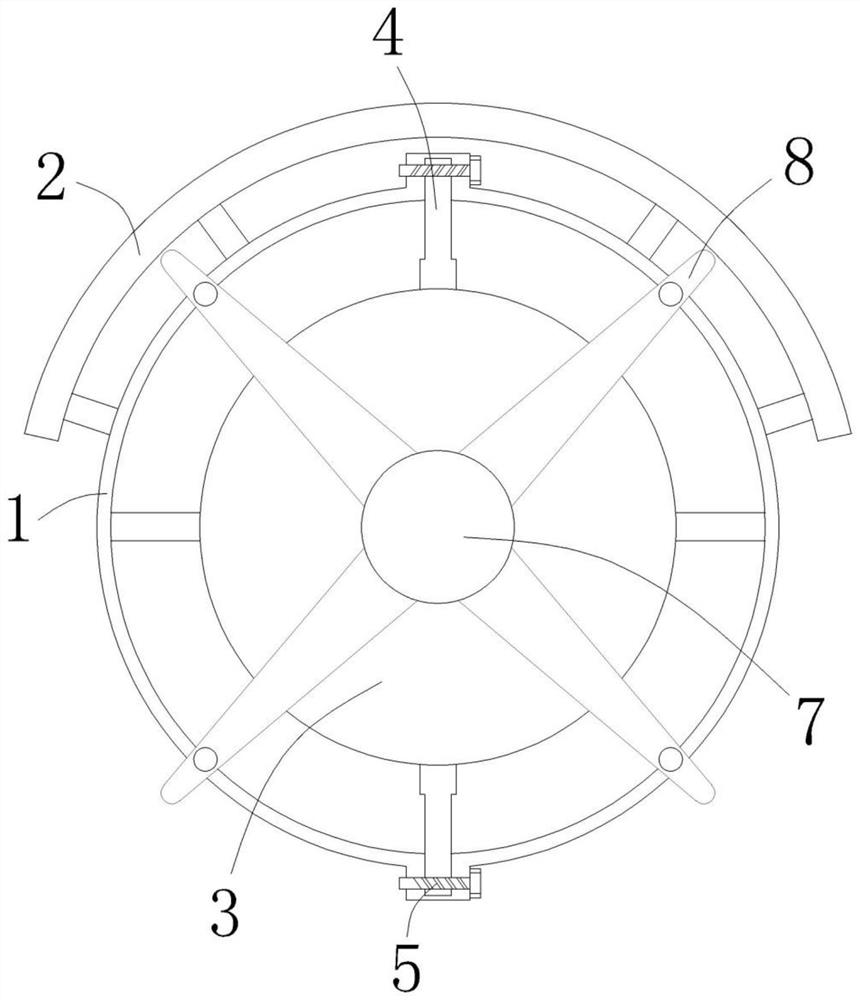

Automobile hub automatically-adjusted targeted polishing mechanism

InactiveCN108115522AGood effectNot easily damagedGrinding drivesGrinding machinesMechanical engineeringEngineering

The invention discloses an automobile hub automatically-adjusted targeted polishing mechanism. The automobile hub automatically-adjusted targeted polishing mechanism comprises a frame; a rotating mainshaft is hinged to the middle top surface of the top plate of the frame, and the bottom end of the rotating main shaft extends out of the middle bottom surface of the top plate of the frame and is fixedly provided with a transmission gear; a lower support rack is fixed onto the bottom surface of the top plate of the frame and fixedly provided with a rotating servo motor; the middle of the top endsurface of the rotating main shaft is provided with a positioning column; a lower elastic clamping block is inserted into the positioning column, the positioning column is inserted inside a central through hole of a hub, and the top end of the positioning column extends out of the top surface of the hub and inserted with an upper elastic clamping block; the top surface of the top plate of the frame is fixedly provided with two vertical plates which are arranged on both sides of the rotating main shaft, the opposite walls of the two vertical plates are fixedly provided with positioning cylinders, and the push rods of the positioning cylinders penetrate through the vertical plates and are fixedly provided with arc blocks. The automobile hub automatically-adjusted targeted polishing mechanism can automatically fix, rotate and position the hub and polish corresponding parts, thereby being good in effects and less prone to damage.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

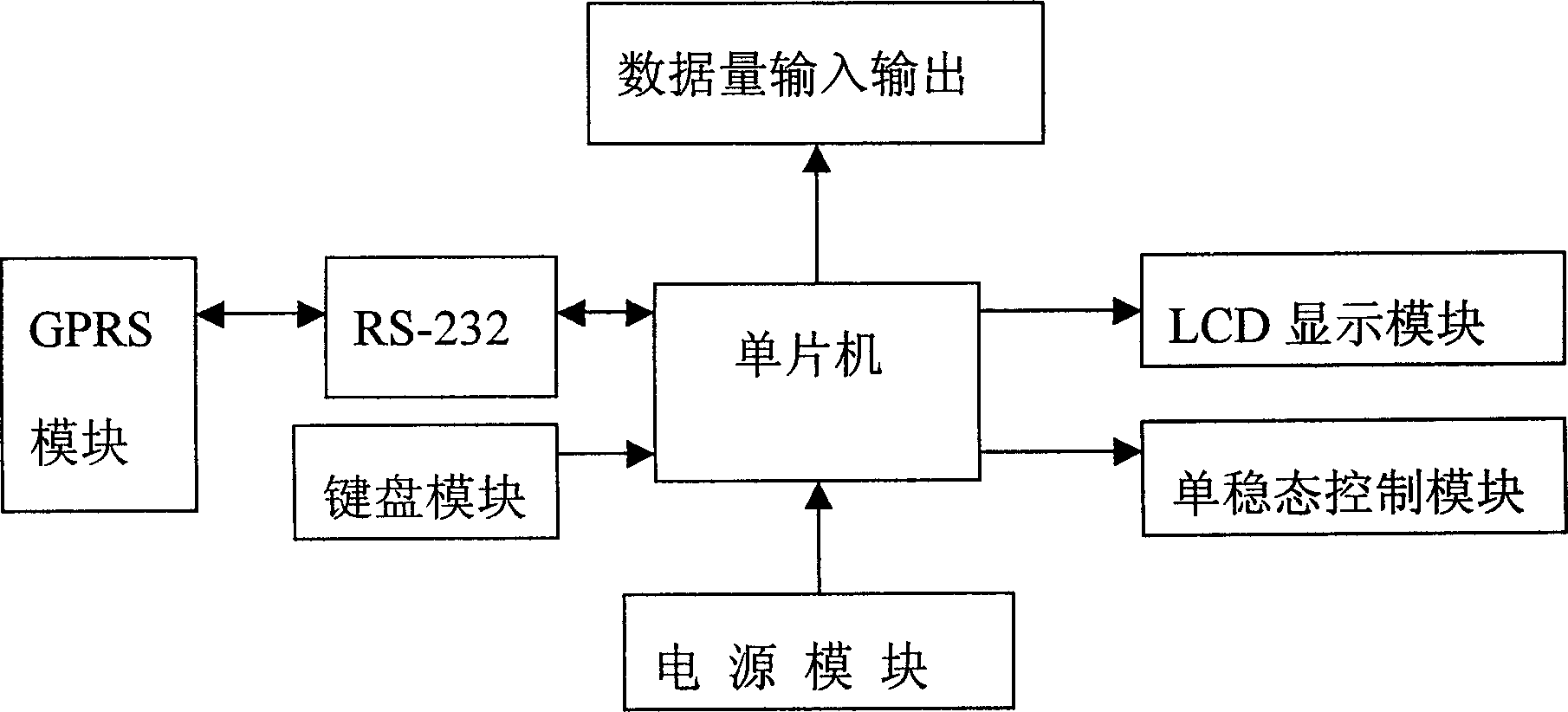

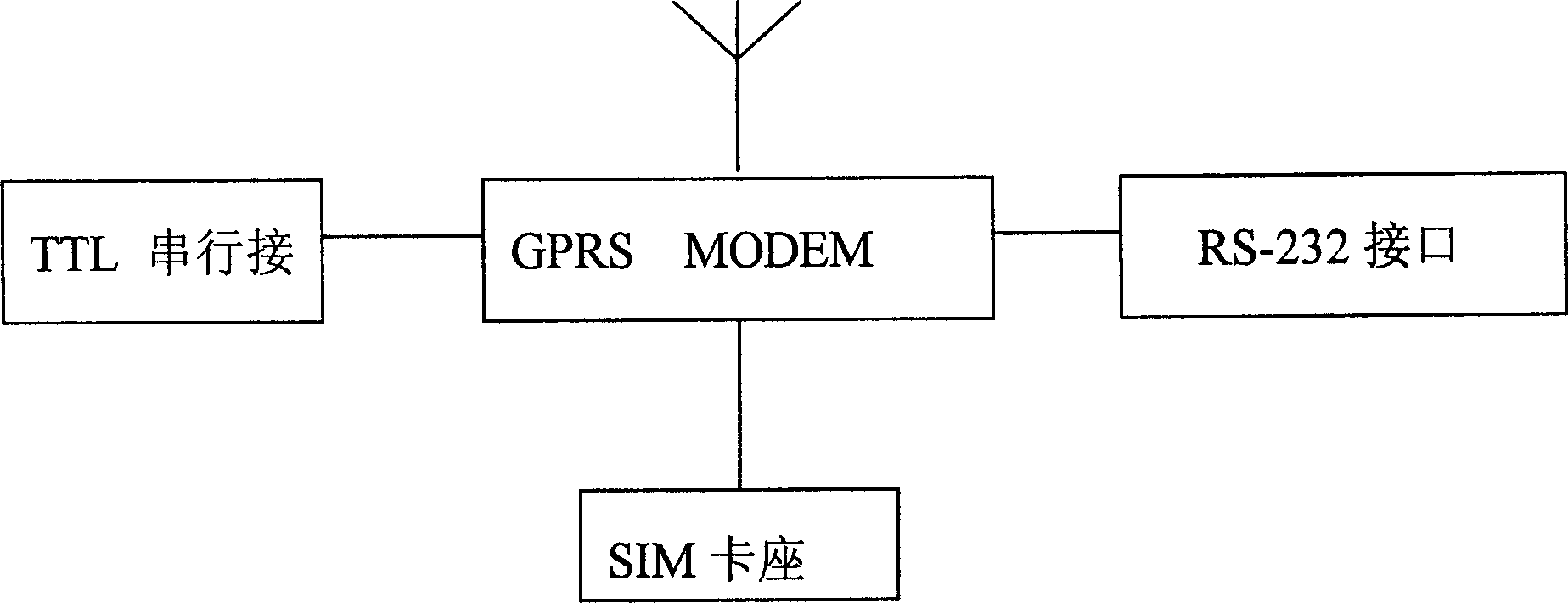

Single stable state piston type data transmission intelligent water meter

InactiveCN1904564AClose freeNot easily damagedTransmission systemsVolume indication and recording devicesData transmissionPiston cylinder

The invention relates to a kind of monostable piston data-transmission intelligent water meter. It is a high-performance new-type automatic and intelligent water meter and possesses the function of automatic meterage, data statistic, data analysis, data transmission and long-distance real-time monitor. It includes a base meter. The base meter and the valve body are connected by the flange. Under the valve body sets the piston valve including a piston cylinder, a piston and a pressure balanced spring. In the upper cover of the piston valve sets a balance path. On the valve body set a computer controlling part with wireless transmission module and a monostability controller. The computer controlling part receives impulse signal and sends out the order to the monostability controller. The monostability controller controls the water check closing or opening the water stopping hole in the balance path. The order sent out by the computer controlling part is transmitted to the CSM memorizer in the controller. The CSM memorizer processes and transmits data to the display. The information is transmitted to the long-distance computer by inner GPRS data transmission module.

Owner:郭宝军

Automatic rotating and grinding mechanism for automobile hub

InactiveCN107932219AGood effectNot easily damagedGrinding carriagesRevolution surface grinding machinesMechanical engineeringEngineering

The invention discloses an automatic rotating and grinding mechanism for an automobile hub. The mechanism comprises a rack; a rotating spindle is hinged to the top surface of the middle of a top plateof the rack; a rotating servo motor is fixed on the bottom surface of the middle of the top plate of the rack; an output shaft of the rotating servo motor is a spline shaft; the spline shaft is inserted in and sleeved with a spline hole formed in the bottom end of the rotating spindle; a positioning column is arranged in the middle of the top end surface of the rotating spindle; the positioning column is inserted in and sleeved with a lower elastic clamping block; the positioning column is inserted in and sleeved with a central through hole of the hub; the top end of the positioning column extends out of the top surface of the hub and is inserted in and sleeved with an upper elastic clamping block; a threaded connection part is arranged at the top end of the positioning column, extends out of the upper elastic clamping block and is in threaded connection with an upper cover plate; the upper cover plate is pressed against the top surface of the upper elastic clamping block; and a middle block at the central through hole of the hub is clamped between the upper elastic clamping block and the lower elastic clamping block. By the aid of the mechanism, the hub can be fixed and rotated automatically, the corresponding part can be ground automatically, the effect is good, and the hub is not prone to damage.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

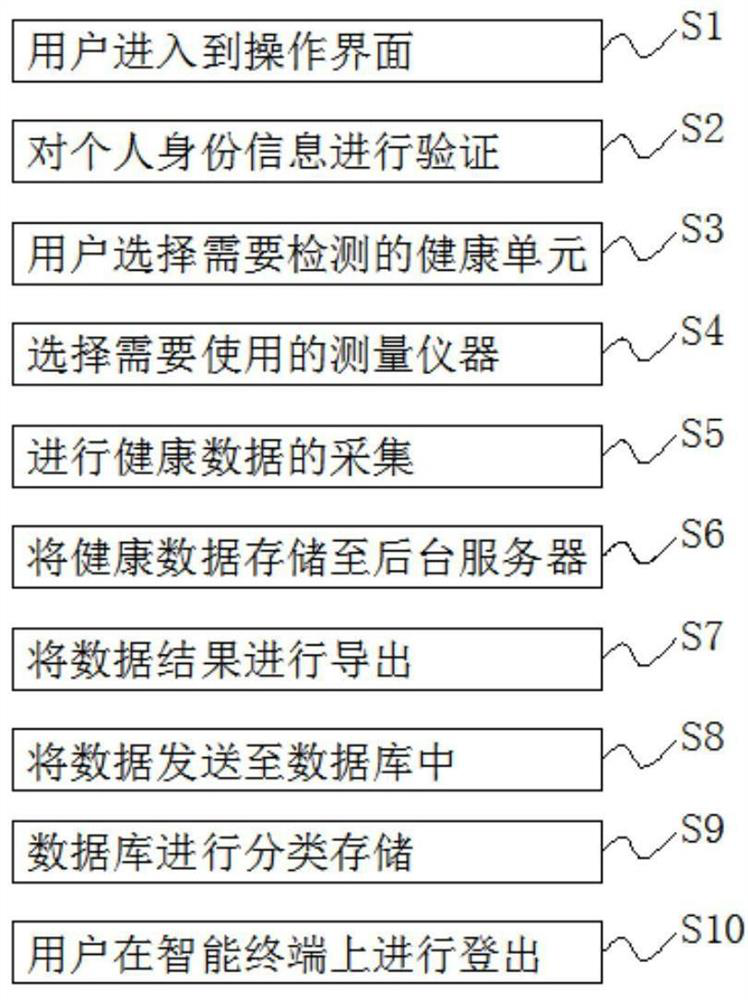

Automatic health data acquisition method

PendingCN112786133AGet it in timeEnsure safetyDigital data protectionDigital data authenticationOccurrence dataData acquisition

The invention discloses an automatic health data acquisition method, which belongs to the technical field of health data management, and comprises the following steps: S1, entering, by a user, the operation interface; s2, verifying the personal identity information; s3, selecting, by the user, a health unit needing to be detected; s4, selecting a measuring instrument needing to be used; s5, collecting health data; s6, storing the health data to a background server; s7, exporting a data result; s8, sending the data to a database; s9, carrying out classified storage by the database; and S10, logging out on the intelligent terminal by the user. Through autonomously selecting the detected health unit, the user can timely and quickly acquire the selected health data, track the health state of the user by using the intelligent terminal in real time, and timely store the health data in the block chain through the server in real time for encryption storage, so that the safety of the health data during collection is ensured, and the user experience is improved. Therefore, the problems of data damage and loss are not easy to occur.

Owner:广东飞企互联科技股份有限公司

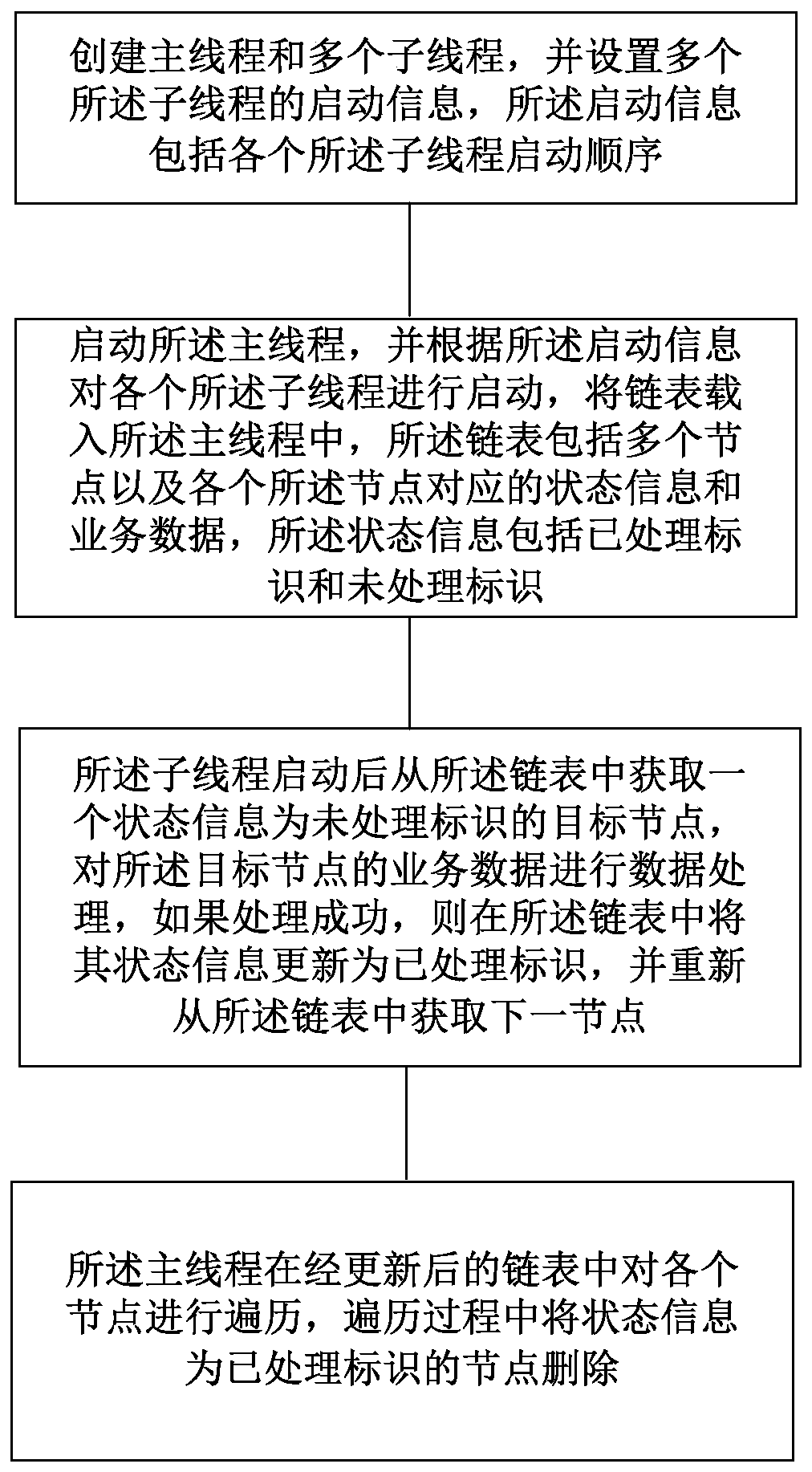

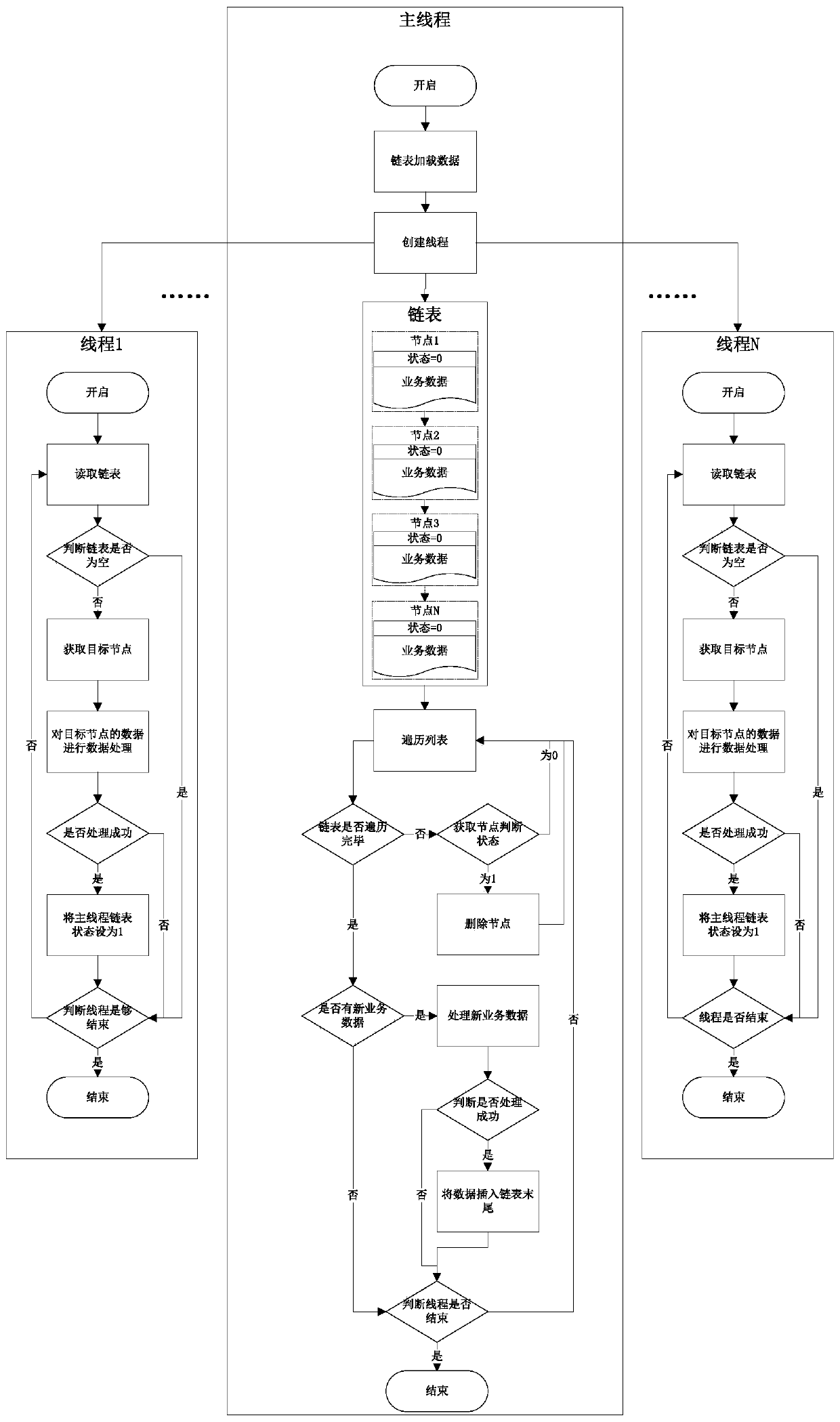

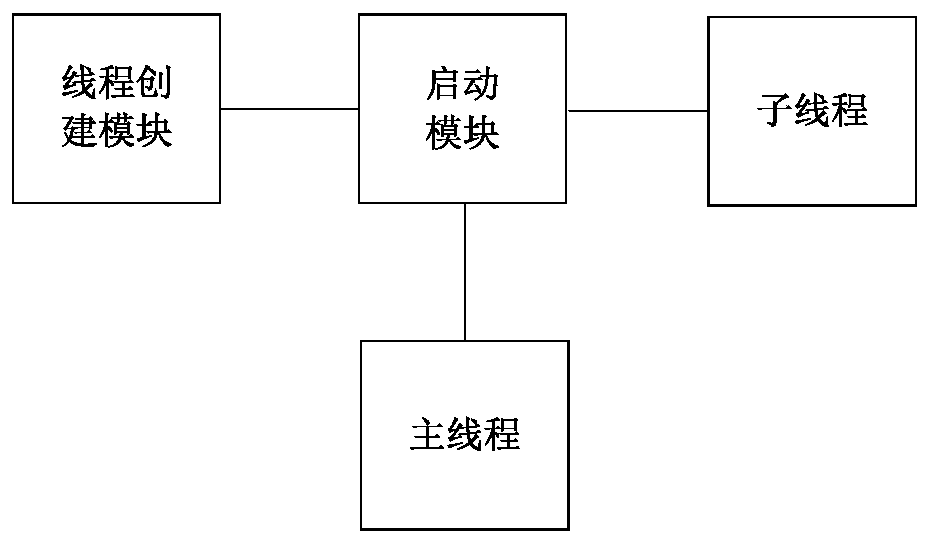

Multi-thread linked list processing method and device and computer readable storage medium

InactiveCN110598054AImprove processing efficiencyNot easy to breakProgram synchronisationOther databases indexingProcess identificationComputer science

The invention provides a multi-thread linked list processing method and device and a computer readable storage medium. The multi-thread linked list processing method comprises the steps: building a main thread and a plurality of sub-threads, enabling a linked list to be loaded into the main thread, and enabling state information to comprise a processed identification and an unprocessed identification; after the sub-thread is started, obtaining a target node with an unprocessed identifier from the linked list, carrying out data processing on the data of the target node, if the processing succeeds, updating the state information of the target node into a processed identifier in the linked list, and obtaining the next node from the linked list again; and traversing each node in the updated linked list by the main thread, and deleting the node of which the state information is the processed identifier in the traversing process. According to the multi-thread linked list processing method, the main thread and the plurality of sub-threads are adopted to process the data together, and the state information of the nodes is added into the data of the linked list, and the plurality of sub-threads process the data of the nodes in the linked list in parallel, and the influence on other sub-threads does not need to be considered, and the data processing efficiency is improved, and the linkedlist is not easy to damage.

Owner:GUILIN CHANGHAI DEV

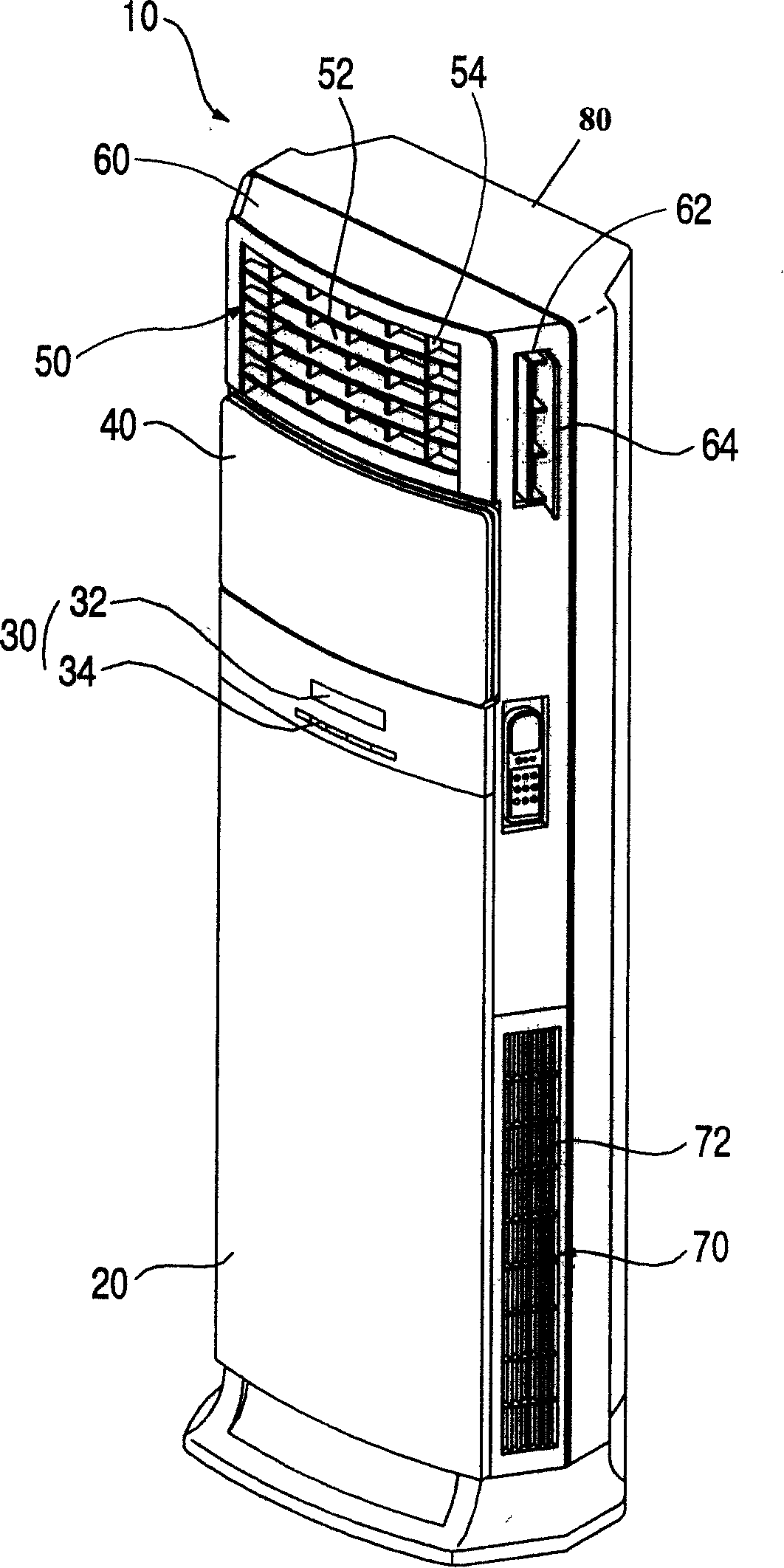

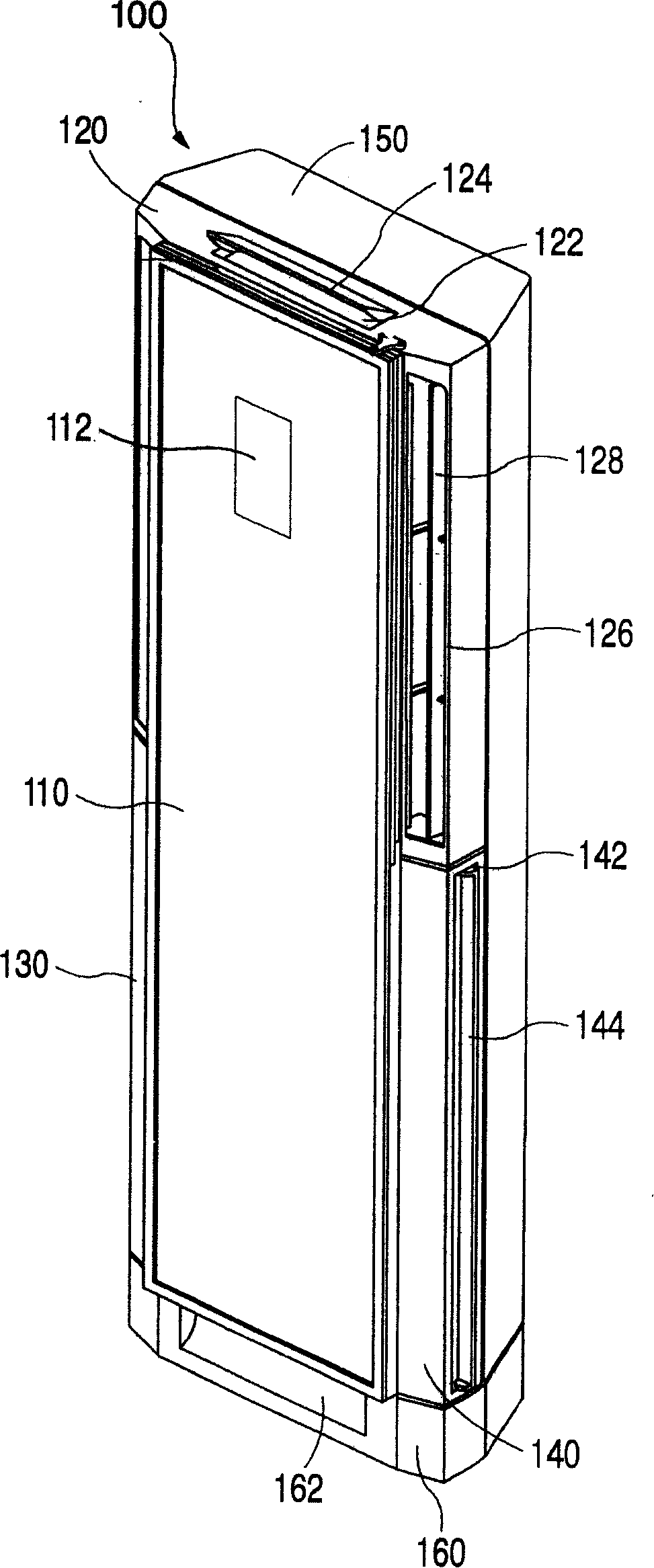

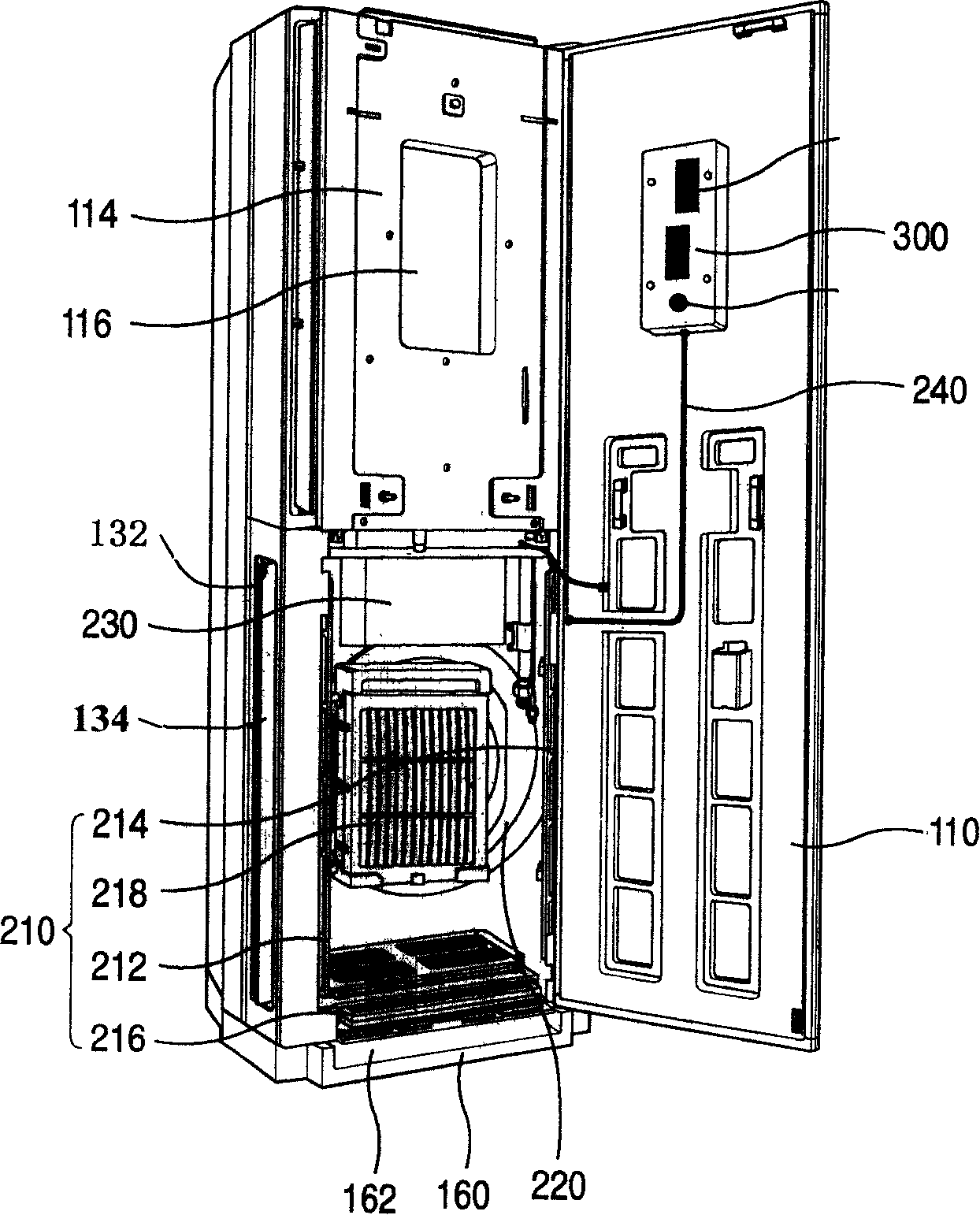

Indoor machine of air conditioner

InactiveCN101173776AImprove stabilityNot easily damagedLighting and heating apparatusAir conditioning systemsEngineeringDisplay device

The invention relates to an indoor unit of an air conditioner. The invention discloses an indoor unit of air conditioner, which comprises a body, a front faceplate, a display cover, a display part, a display housing, a touch screen, an LCD and an LCD control part. The body forms the indoor space and accommodates a plurality of air conditioner components. The front faceplate forms the front appearance of the body. The display cover is arranged behind the front faceplate and accommodates electronic components. The display part is arranged in the display cover, displays the working state of the body and operates the body. The display housing encases the display part. The display part comprises a touch screen, an LCD and an LCD control part, wherein the touch screen control the working state of the body; the LCD is arranged behind the touch screen and displays the working state of the body; the LCD control part controls the LCD. The invention has an advantage of diversified display forms.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

Injection mold facilitating rapid mold releasing

Owner:徐州海之慧生物技术有限公司

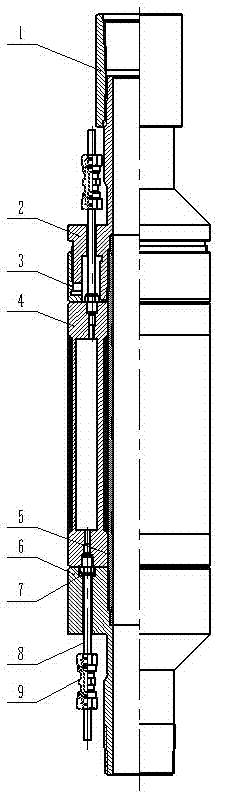

Ground hydraulic control airbag type full-metal sealing packer

PendingCN107023273ANot easily damagedImprove usability and reliabilitySurveySealing/packingOil wellEngineering

The invention discloses a ground hydraulic control airbag type full-metal sealing packer which comprises a center pipe and a setting airbag, and the center pipe is sleeved with the setting airbag. The interior of the setting airbag is a cylindrical cavity. The two axial end faces of the setting airbag are provided with axial liquid flowing channels communicating with the cylindrical cavity. An outer port of each liquid flowing channel is provided with a hydraulic control pipeline joint. The setting airbag is machined in a 3D integral printing mode and is made of 316 stainless steel metal with good ductility and elasticity, and the inner wall and the outer wall of the setting airbag are coated with metal material layers with good airtightness and adhesion. The upper end and the lower end of the center pipe are provided with an upper joint and a lower joint correspondingly. The upper joint and the lower joint are provided with hydraulic control pipeline channels communicating with the liquid flowing channels. Packing of oil reservoirs is achieved in a hydraulic control full-metal sealing mode, and a guarantee is provided for long-term effective slice mining of high temperature and high pressure oil-water wells.

Owner:CHINA PETROLEUM & CHEM CORP +1

Paper transmitting device suitable for splitting machine

InactiveCN103130020AEnhance static electricityNot easily damagedArticle deliveryWebs handlingPaper sheetIndustrial engineering

The invention discloses a paper transmitting device suitable for a splitting machine. The paper transmitting device comprises a reel arranged on the splitting machine and a paper tube sleeved on the reel, paper is wound on the surface of the paper tube, a conveying device capable of conveying paper and plates is arranged on one side of the reel, and an electrostatic generator is arranged on one side of the conveying device. Since the electrostatic generator is arranged on one side of the conveying device, static around the conveying device can be enhanced, so that the paper and the plates are combined together during conveying, the plates are effectively protected from being damaged easily.

Owner:昆山中恒铝业有限公司

Strong three-dimensional crimped memory fiber

InactiveCN104562242ANot easily damagedExtended service lifeFilament/thread formingMechanical engineeringPolytrimethylene terephthalate

The invention relates to a strong three-dimensional crimped memory fiber. The fiber is made of PTT (polytrimethylene terephthalate) and has an unequal-length triangular cross section. The fiber has the advantages: 1) the fiber has characteristics of PTT and has the unequal-length triangular cross section, so that the fiber has an orientation difference in a certain direction in a use process, orientates in some direction in the use process and meets service requirements; and 2) adjacent edges are in arc transition, so that a defect of high possibility of damage of the fiber due to bending during extension or compression of the fiber is avoided, the stress at a transition part of the adjacent edges is relatively mild during the extension or compression of the fiber due to the arc transition manner, the excessive stress cannot appear, the fiber is not easy to damage, and the service life of the fiber is prolonged.

Owner:YANGZHOU GUANGTAI CHEM FIBER

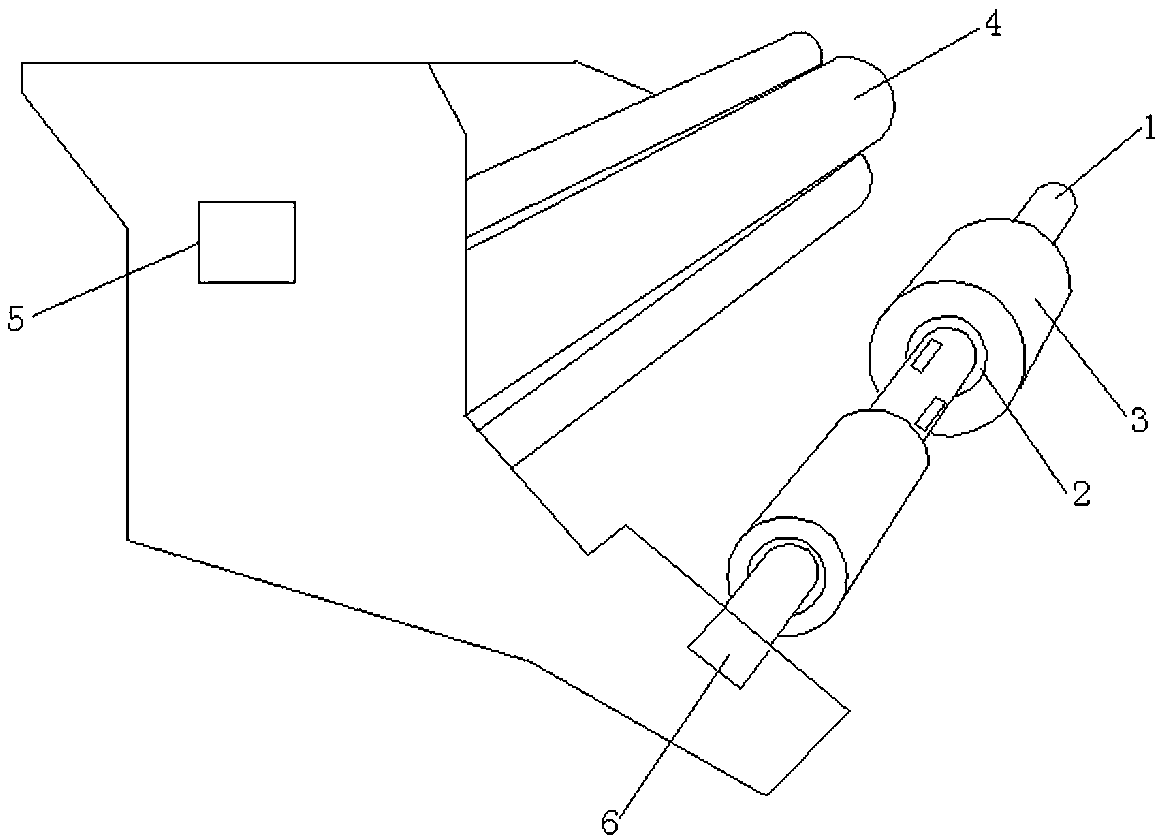

Fixing mechanism for automobile hub

InactiveCN107838841AConvenient manual deburringNot easily damagedWork holdersScrew jointArchitectural engineering

The invention discloses a fixing mechanism for an automobile hub. The fixing mechanism comprises a frame. The middle part of a top plate of the frame is equipped with a mounting groove. The bottom surface of the mounting groove is equipped with multiple locating through holes. A bottom block is inserted into the mounting groove in a sleeving manner. Multiple locating threaded rods of the bottom surface of the bottom block penetrate through the corresponding locating through holes. Bottom ends of the locating threaded rods stretch out of a top plate of the frame and are in screw joint with locating nuts. The locating nuts are pressed against the bottom surface of the top plate of the frame. The bottom surface of the bottom block is equipped with a central support block. The hub is pressed against a top surface of the bottom block. A main connecting block and a middle support block are both located in the hub. The top surface of the middle support block is equipped with a central locating hole. The side wall in the middle part of the central locating hole is provided with a transverse locating screw-joint through hole. Therefore, the fixing mechanism can fix the hub. Burrs are conveniently removed manually. The hub is not likely to damage. Good effect is obtained.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

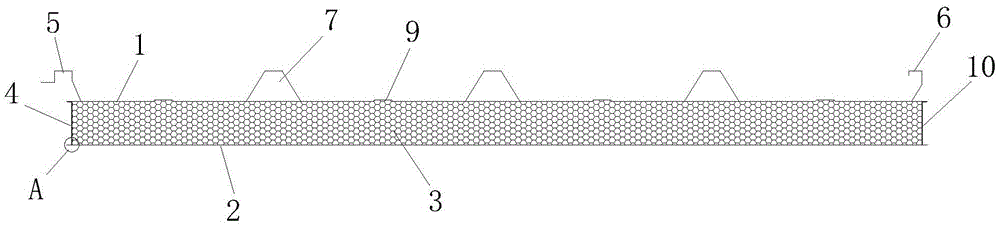

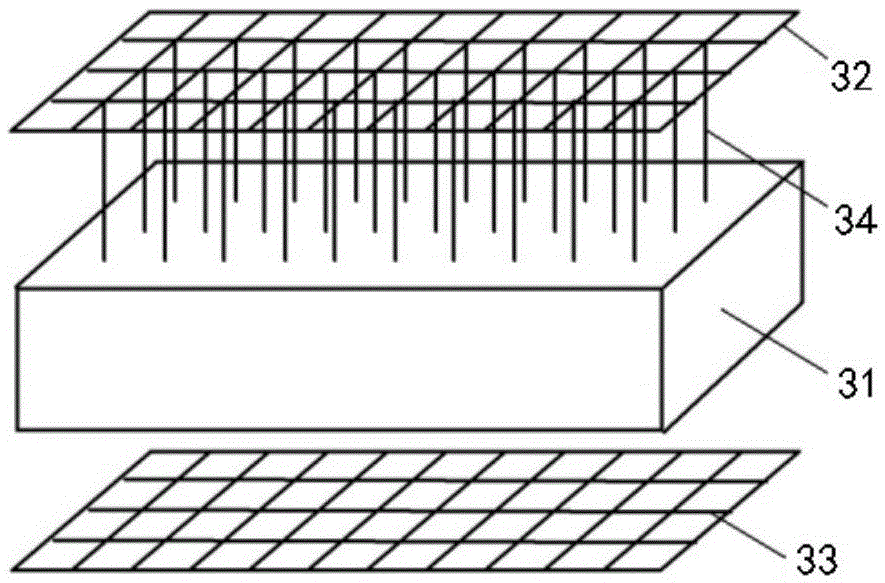

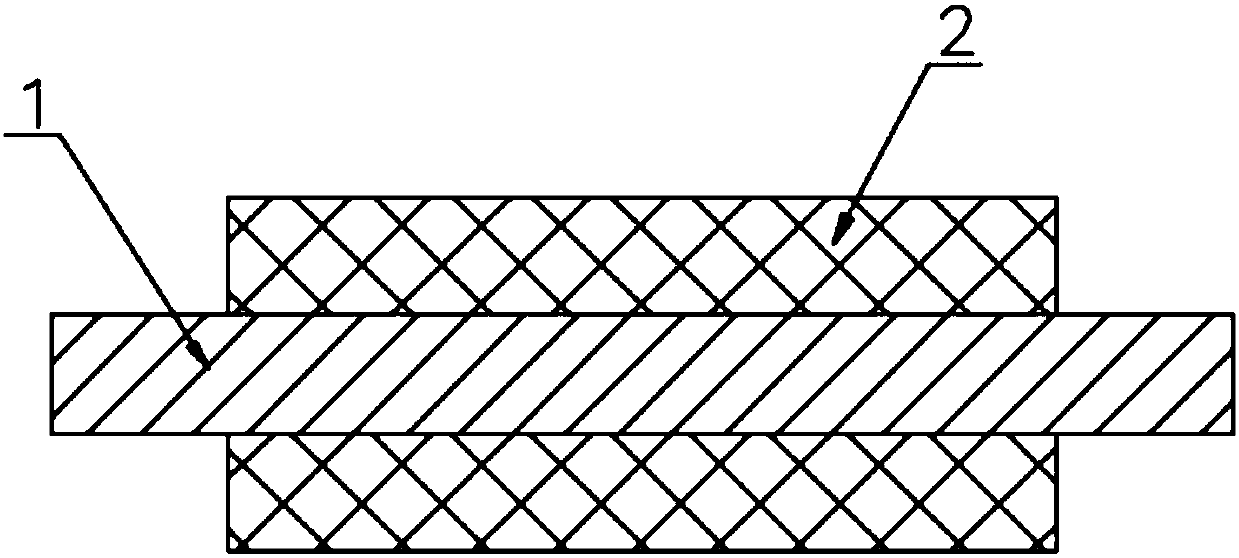

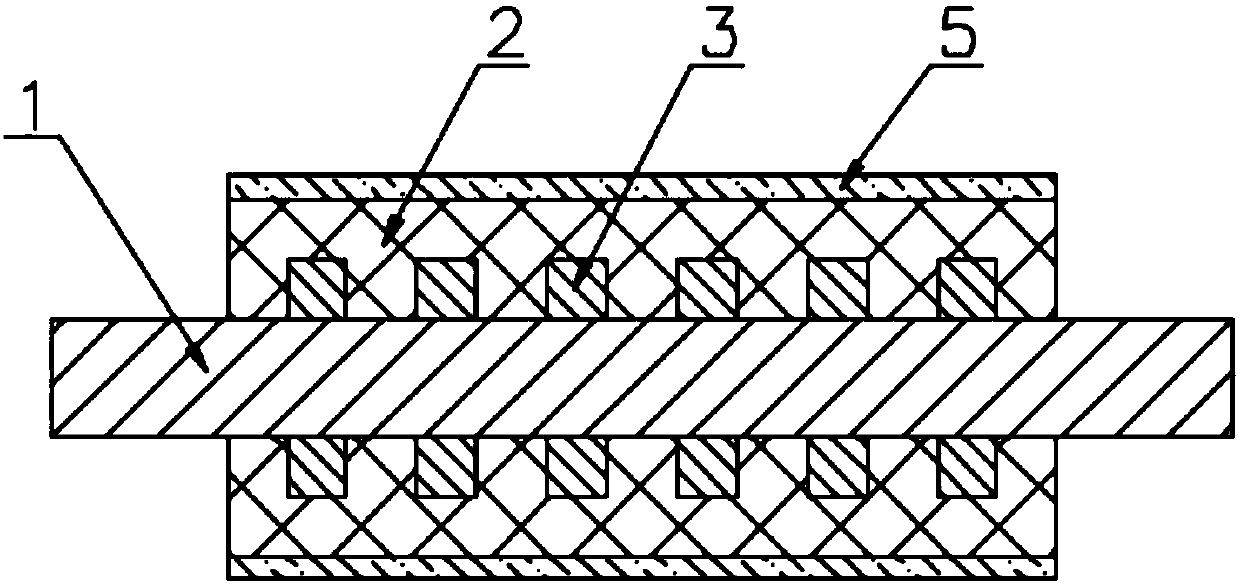

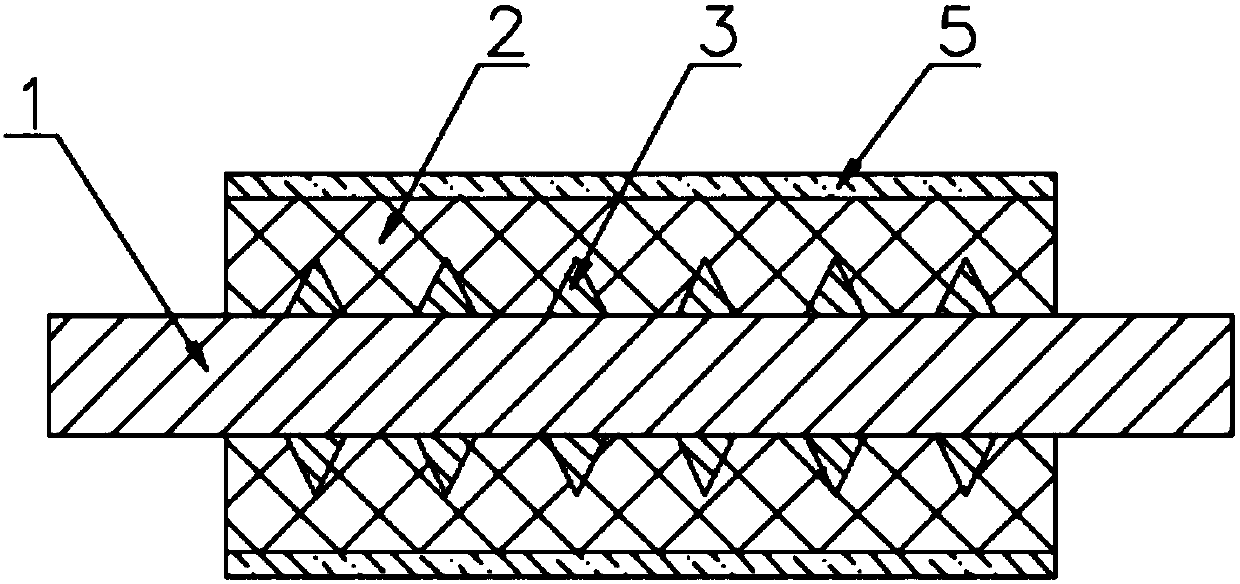

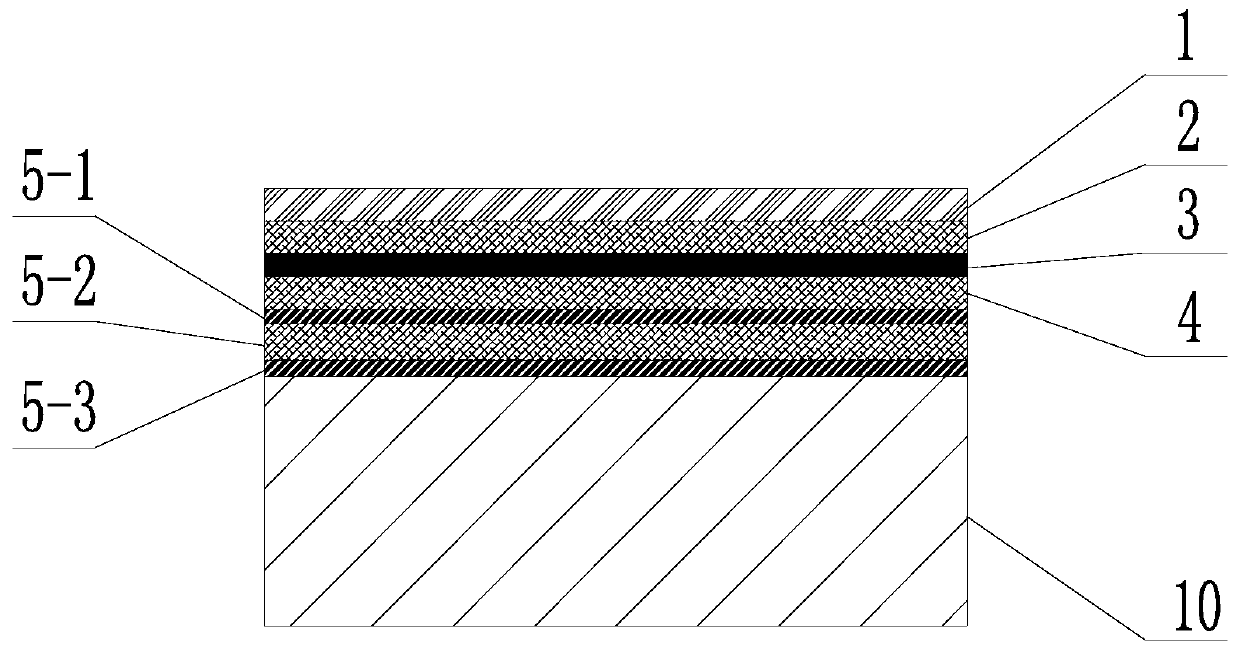

Aluminum alloy rock wool galvanized edge laminboard

InactiveCN105464285AHigh tensile strengthGood dimensional stabilityBuilding componentsMaterials scienceFlange

The invention discloses an aluminum alloy rock wool galvanized edge laminboard. The aluminum alloy rock wool galvanized edge laminboard comprises an upper board and a lower board which are made of aluminum alloy; a rock wool coreboard is arranged between the upper board and the lower board and comprises a rock wool layer, an upper net-shaped structure layer, a lower net-shaped structure layer and a connecting piece, wherein the upper net-shaped structure layer and the lower net-shaped structure layer are arranged on the upper surface and the lower surface of the rock wool layer respectively, the connecting piece penetrates through the rock wool layer and is connected with the upper net-shaped structure layer and the lower net-shaped structure layer, the two sides of the rock wool coreboard are fixed between the upper board and the lower board through n-shaped galvanized edges, the n-shaped galvanized edges are fixedly connected with the upper board and the lower board through nails, a first hasp and a second hasp are arranged on the edges of the two sides of the upper board respectively, a flange is arranged on the first hasp, and a clamping groove matched with the flange is formed in the second hasp. The tensile strength, dimensional stability and compression strength of the aluminum alloy rock wool galvanized edge laminboard are improved, and the aluminum alloy rock wool galvanized edge laminboard has the advantages of being attractive, fireproof, convenient to assemble and disassemble and high in strength, preserving heat, absorbing heat and the like.

Owner:广西玉林实力钢建有限公司

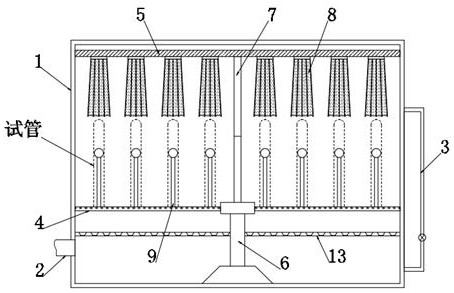

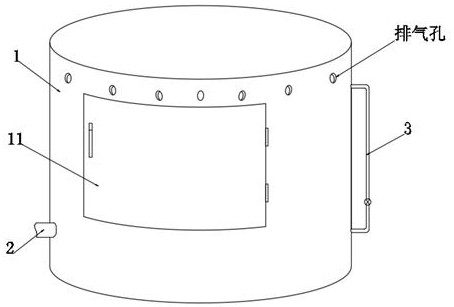

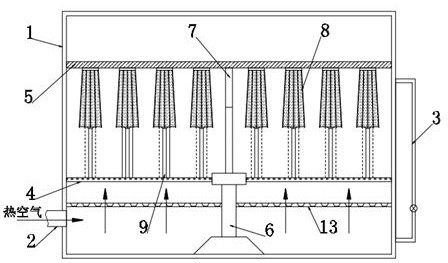

Umbrella type drying equipment for glass test tubes

ActiveCN113446827AImprove drying efficiencyNot easily damagedDrying gas arrangementsDrying chambers/containersTest tubeStructural engineering

The invention discloses umbrella type drying equipment for glass test tubes, and belongs to the field of test tube drying. Through cooperative arrangement of a non-air-receiving disc and air spreading umbrellas, during drying, the air spreading umbrellas are arranged on the outer sides of the test tubes on the non-air-receiving disc. Under the action of hot air from bottom to top, the air spreading umbrellas expand outwards and are separated from the outer surfaces of the test tubes, and form protection rings on the outer sides of the test tubes to effectively protect the test tubes, so that the test tubes are not prone to large displacement in the rotating process of the non-air-receiving disc. Compared with the prior art, the situation that drying is not uniform due to the existence of a fixing piece is effectively avoided, and marks are not prone to being generated after the outer surfaces of the test tubes are dried; and meanwhile, during drying, the variable air sealing strips in the air spreading umbrellas expand under the action of the hot air, and part of hot air in the variable air sealing strips overflows along the surfaces of the variable air sealing strips to be directly blown to the surfaces of the test tubes at the moment, so that the drying efficiency of the test tubes is remarkably improved.

Owner:HAIMENCITY KAHOTEST CITOTEST LABWARE MFG

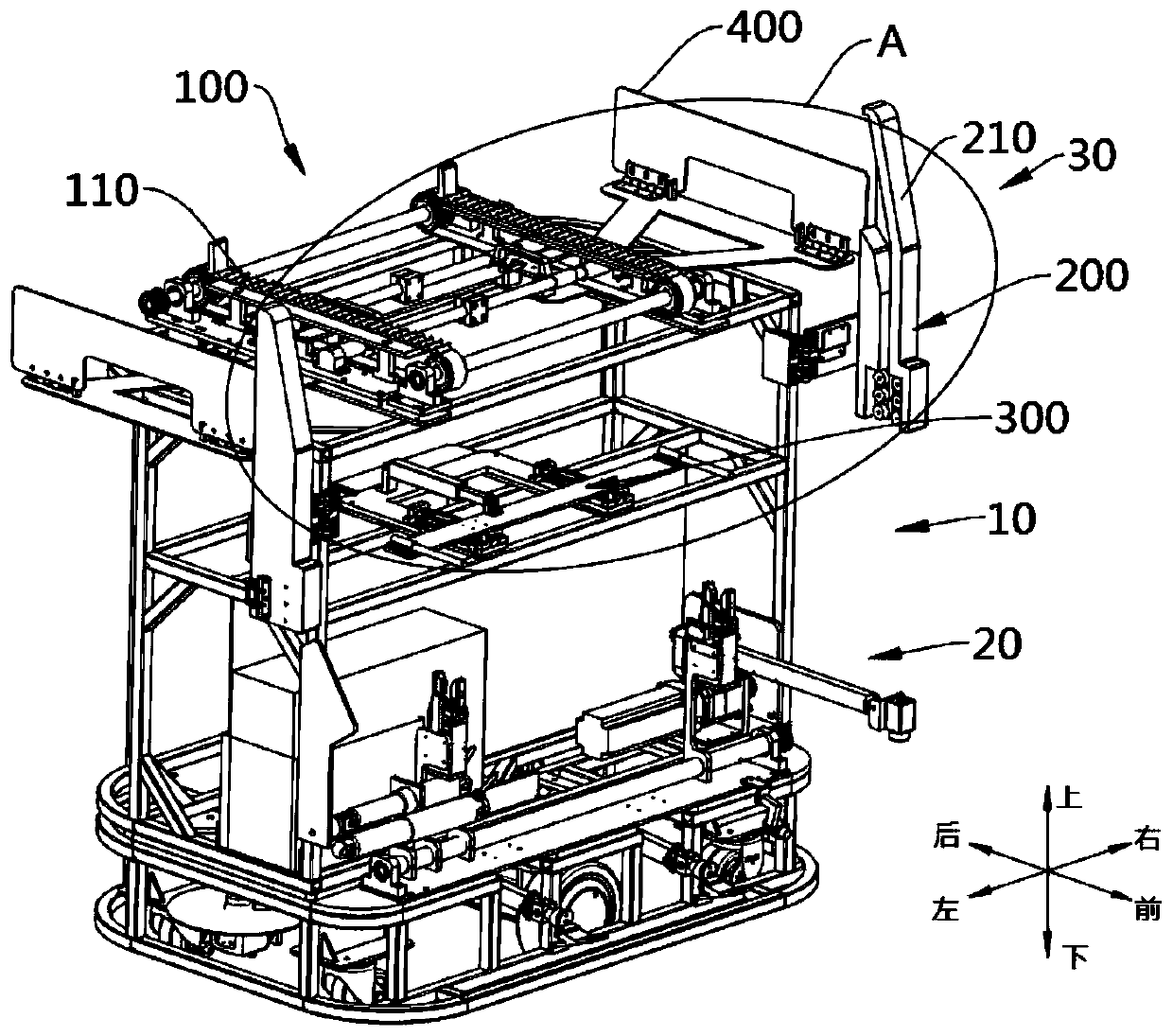

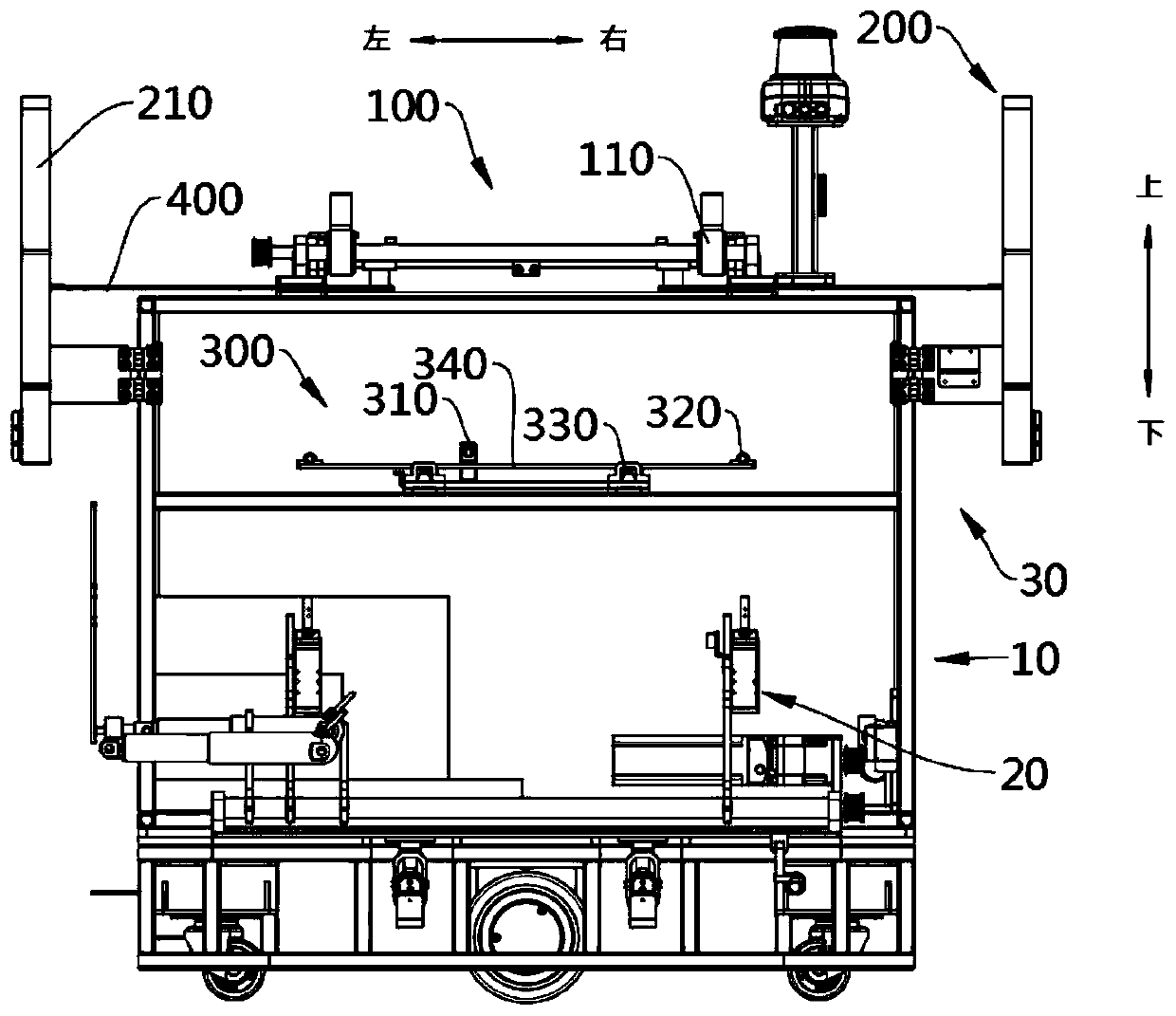

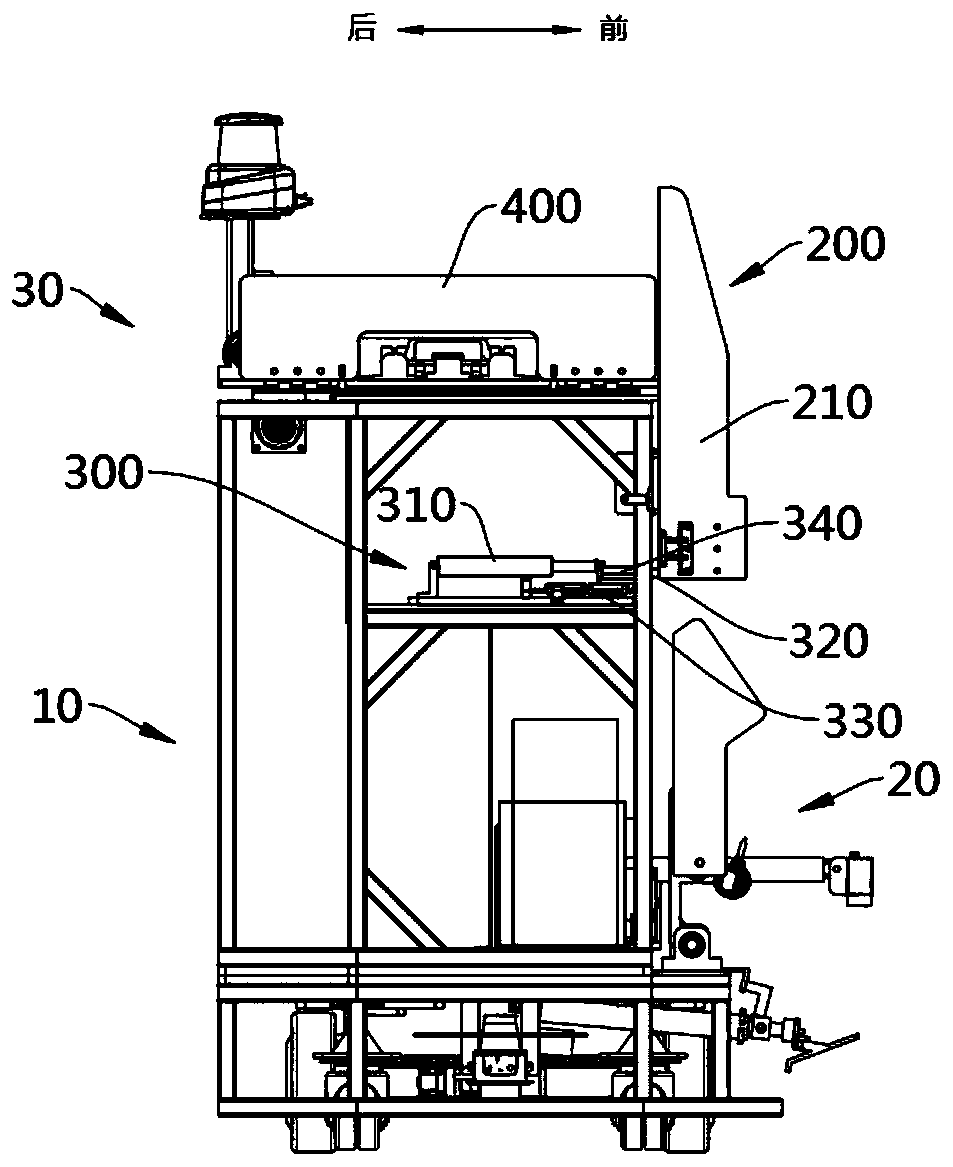

Guiding component, wood floor storage and supply device and wood floor paving robot

ActiveCN110607900AConveying speed controllableNot easily damagedBuilding constructionsFriction forceRolling resistance

The invention relates to the field of building machines, in particular to a guiding component, a wood floor storage and supply device and a wood floor paving robot. The guiding component is mounted onthe wood floor storage and supply device. The wood floor storage and supply device is mounted on the wood floor paving robot. The guiding component is provided with a vertical guide groove. The guidegroove is provided with a buffer structure. The buffer structure comprises two groups of clamping rollers used for clamping wood floors in mutual cooperation. At least one group of clamping rollers are elastically connected with the guiding component so that the distance between the two groups of clamping rollers can be adjusted. By arranging the buffer structure comprising the two groups of clamping rollers in the guide groove, the elastically arranged clamping rollers are pushed aside when the wood floors fall to the position of the two groups of clamping rollers, accordingly, the wood floors can enter the position between the two groups of clamping rollers and fall down in the state of being clamped by the two groups of clamping rollers, and the falling speed is decreased by means of the rolling friction force between the clamping rollers and the wood floors.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

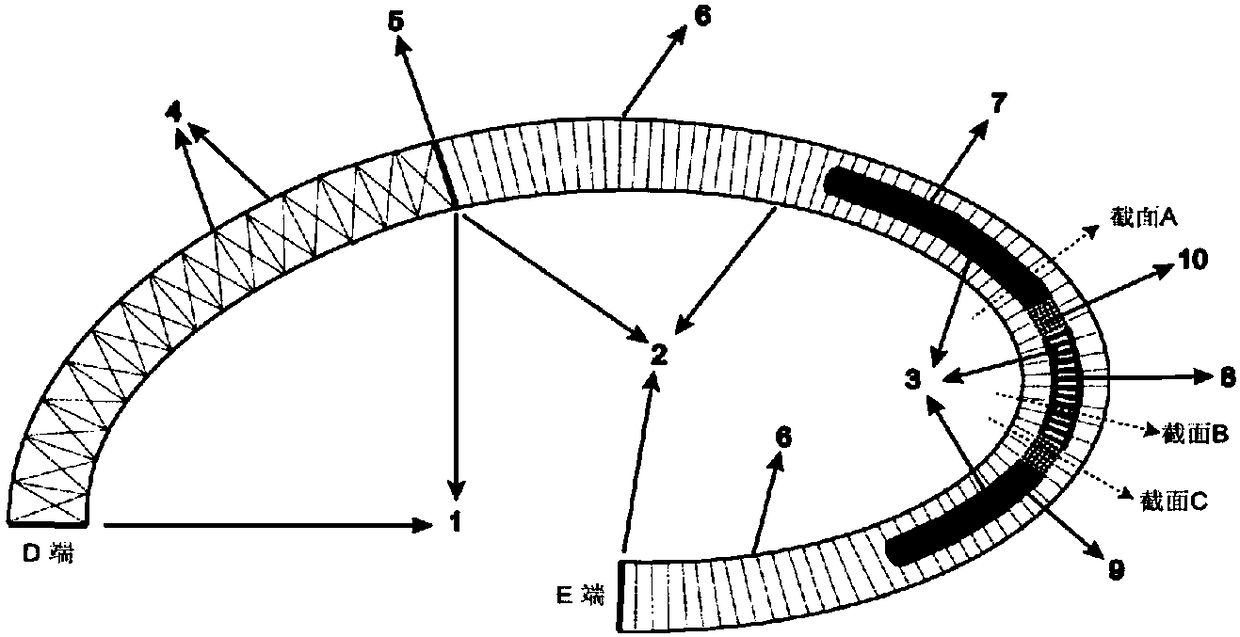

Tricuspid valve forming ring with adjustable length and angle

PendingCN108478310ASimple processing technologyNot easily damagedAnnuloplasty ringsEngineeringDisease

The invention provides a tricuspid valve forming ring with adjustable length and angle. The tricuspid valve forming ring is composed of a cuttable part and a non-cuttable part, the non-cuttable part is composed of a rigid stent and a soft stent, the rigid stent is closely fastened to the inner wall of the soft stent, the rigid stent is divided into five sections, and the bending angle of arcs of front and rear sections can be adjusted in the force state, so that timely intraoperative adjustment is conducted to better adapt to the expansion of tricuspid annuluses of different diseases and better restore the sizes and shapes of the tricuspid annuluses, three middle sections are concentrated points of dispersed stress, and the two ends can be twisted perpendicularly to the plane of a tricuspid annulus to conform to the shape change of a heart. The tricuspid valve forming ring has the advantages of reasonable design, convenient use, strong adaptability and good myocardial compliance, and is an implantable artificial heart valve forming ring, and the problems that the forming effect is affected by inaccurate matching, inability to adjust the angle of a ring after intraoperative formingand the like due to the fact that an existing forming ring cannot consider both formability and myocardial compliance and a tricuspid annulus and the geometrical morphology of the forming ring are notmatched are solved.

Owner:倪一鸣 +1

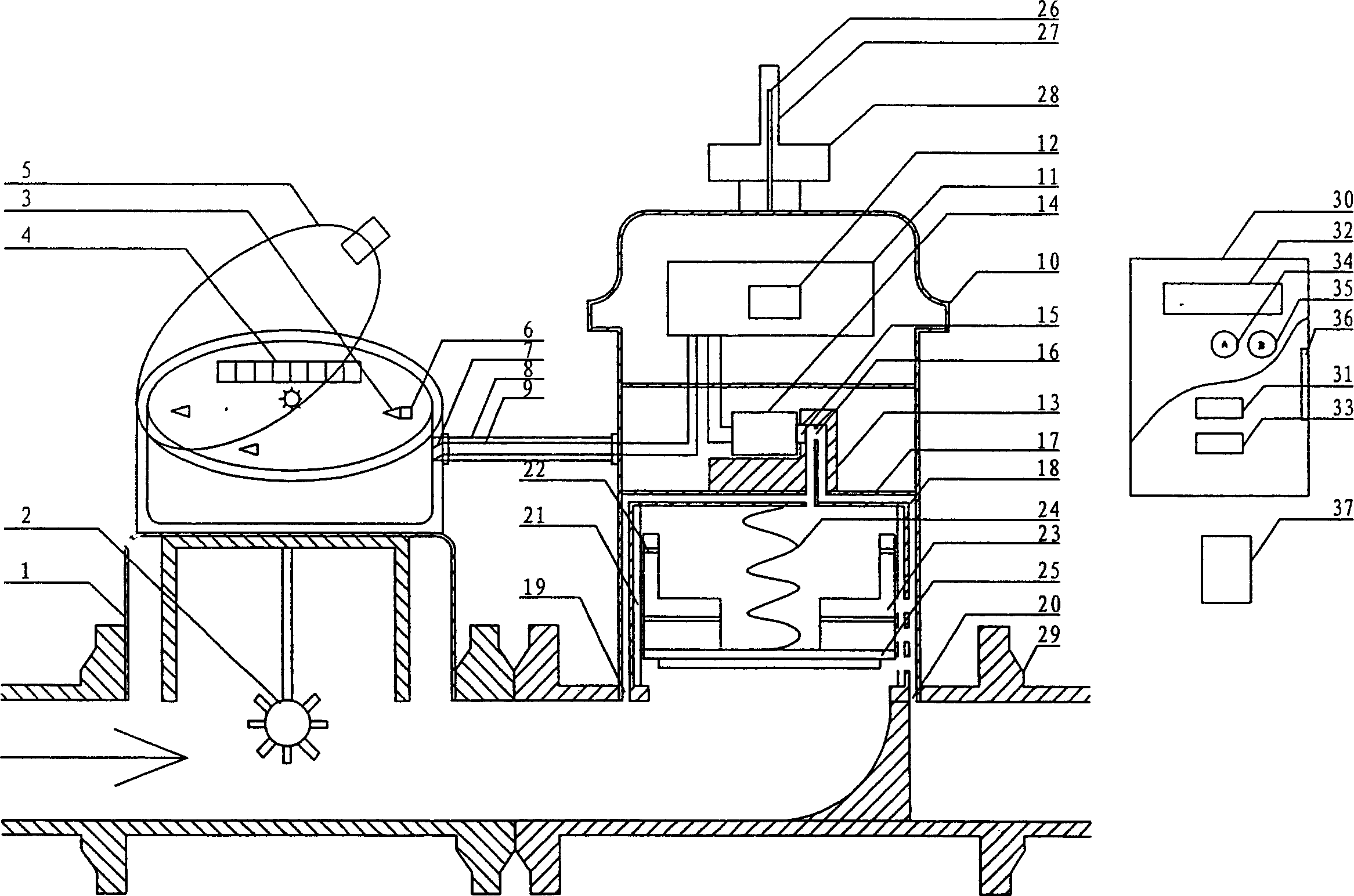

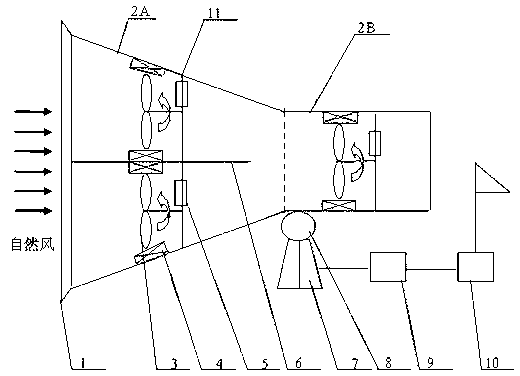

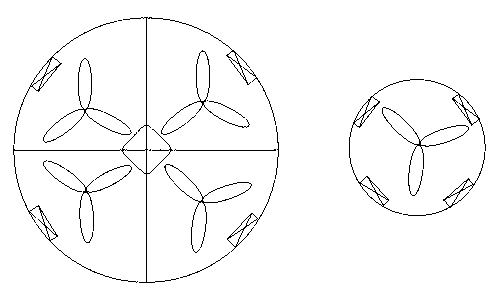

Composite two-stage wind power generation device in pipeline

InactiveCN102996363ANot easily damagedIncrease profitBatteries circuit arrangementsWind motor controlAutomotive engineeringWind force

The invention provides a composite two-stage wind power generation device in a pipeline. The composite two-stage wind power generation device comprises an assembly which is formed by connecting a flow collector, wind power generator devices, wind turbine blades, coils, permanent magnets, storage batteries, stepper motors, a wind direction sensor, a control circuit, a support, a funnel type pipeline with a cylindrical pipeline, wherein the flow collector is arranged at a wind collecting device, namely, a funnel type pipeline port; the wind power generator devices are provided with gear transmissions; and the wind turbine blades, namely, magnetism conductive blades have the magnetism conductivity. Aiming at the problems that an ordinary wind power generation device is limited by the wind speed and the wind energy utilization rate is low in the power generation process, the invention provides the composite two-stage wind power generation device in the pipeline so as to convert the wind energy into electric energy more effectively.

Owner:CHANGZHOU UNIV

Pressure-resistant anti-shedding rubber roller

PendingCN107672271ANot easily damagedPut an end to sheddingShaft and bearingsSynthetic resin layered productsEngineeringWaste rubber

Owner:ZHANGJIAGANG HUASHEN INDAL RUBBER PRODS

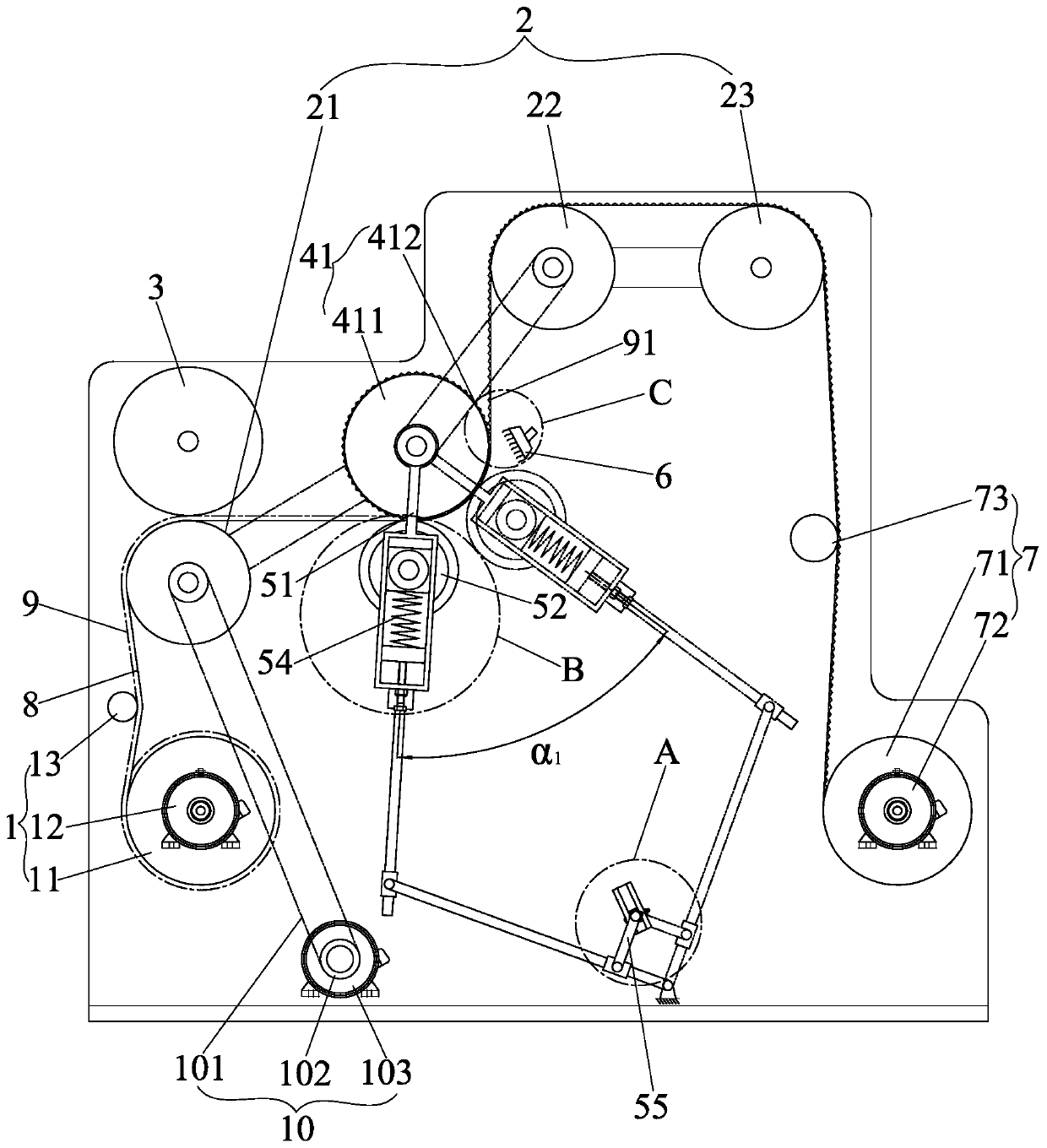

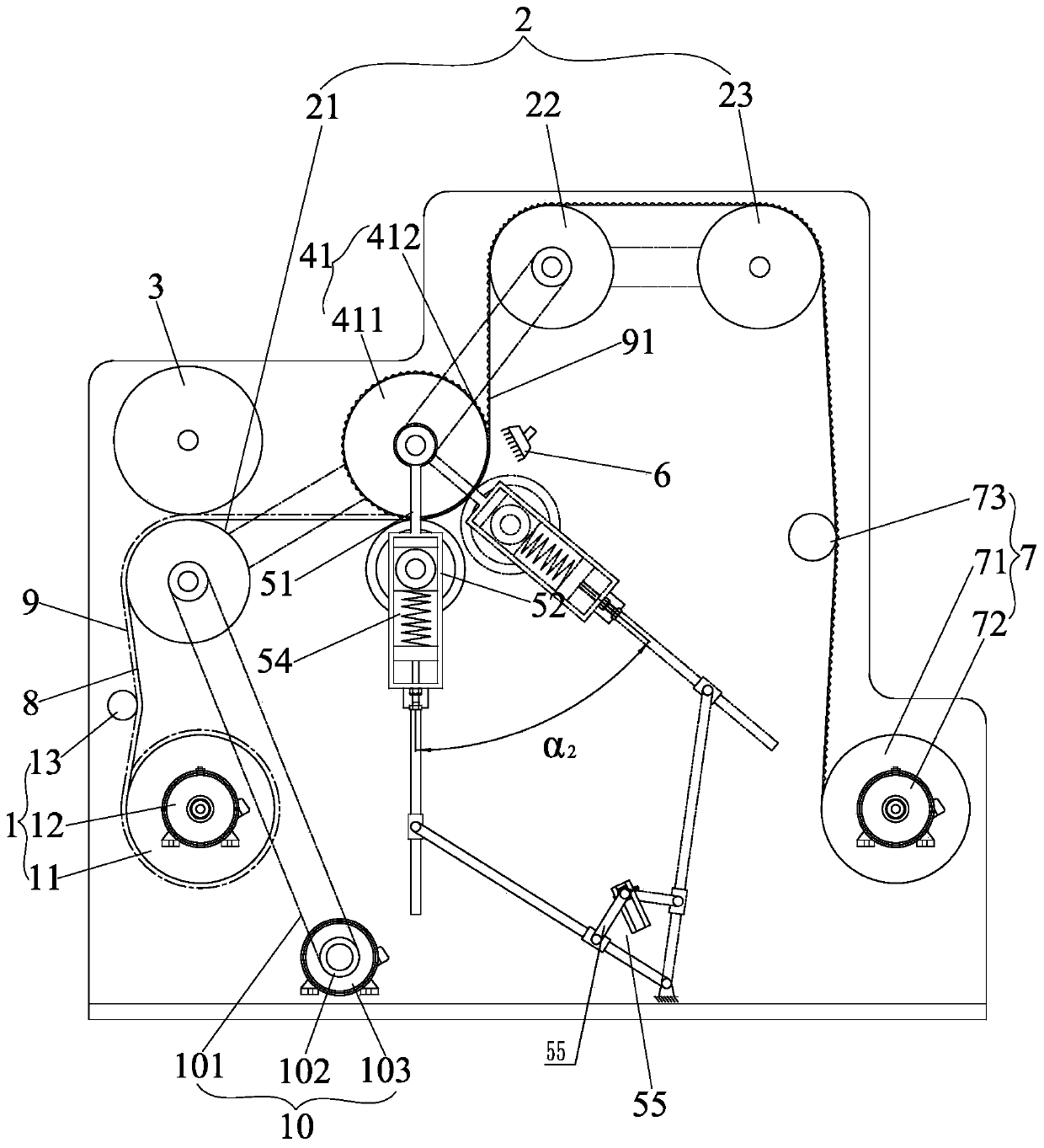

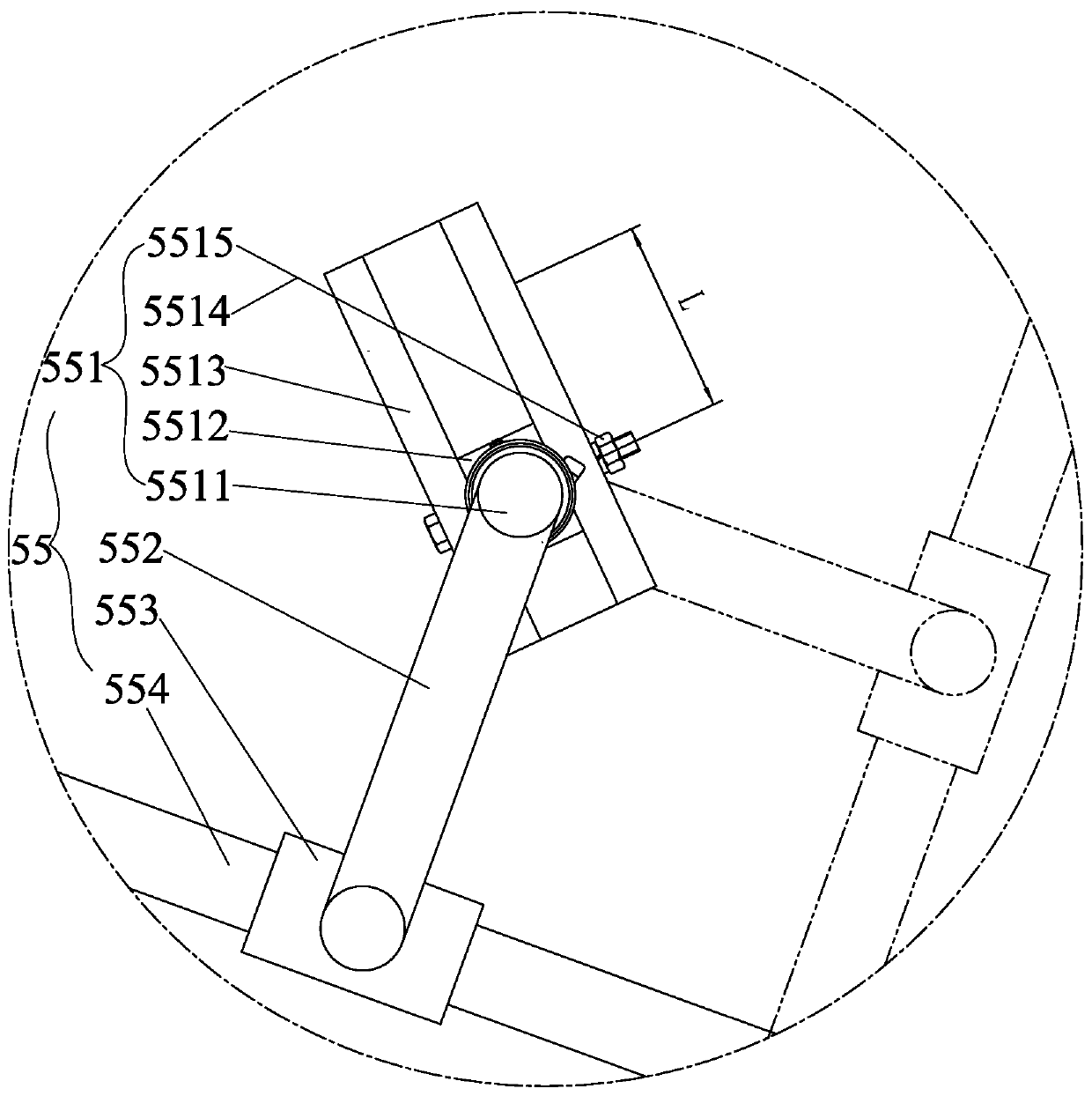

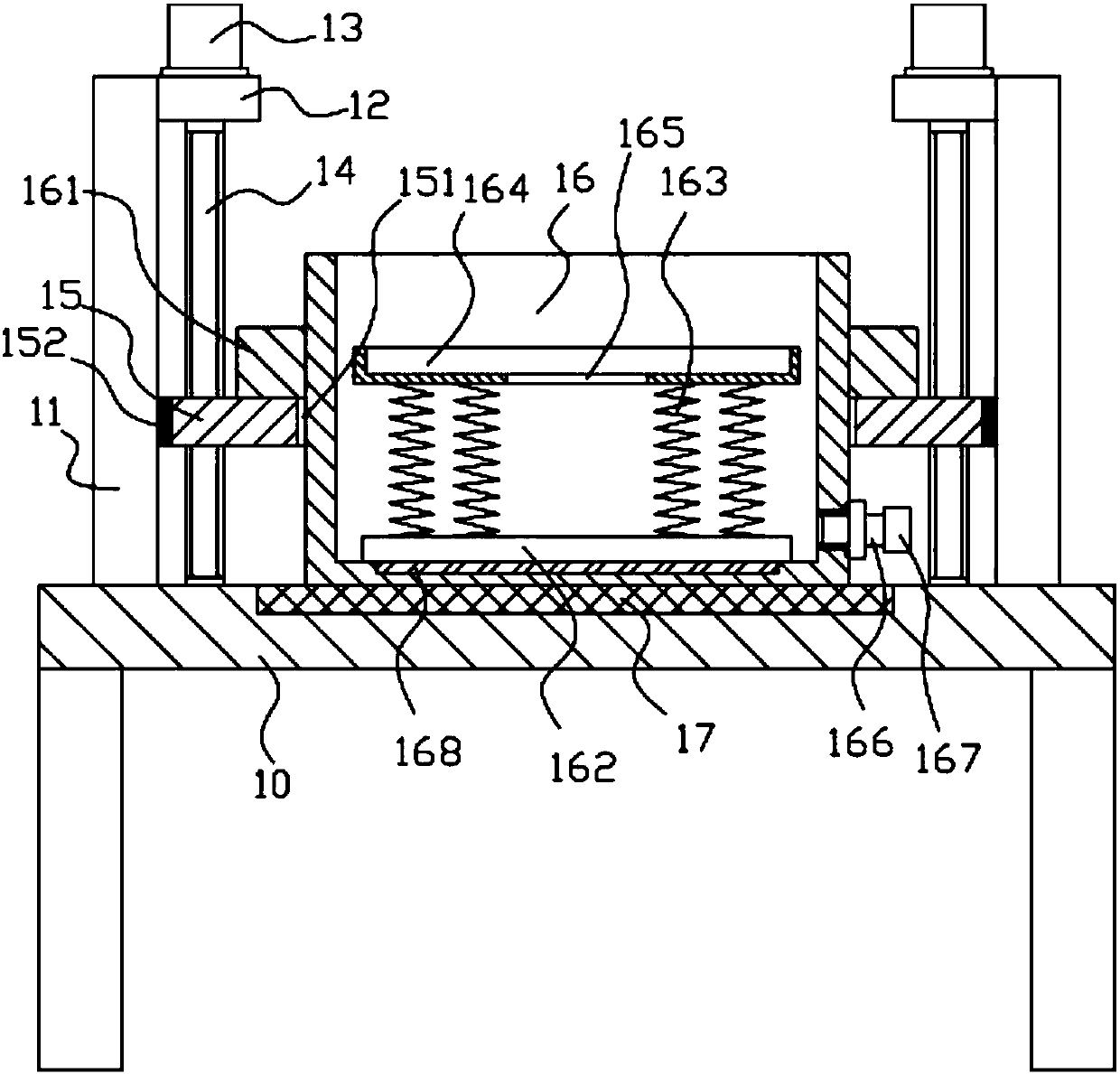

Ultrasonic assisted reciprocating swing roll to fixed roll hot-roll embossing device and embossing method

The invention discloses an ultrasonic assisted reciprocating swing roll to fixed roll hot-roll embossing device and method. The embossing device comprises a roll outlet mechanism, a first guide roller, a heating roller, a centering mold roller, a swing pressure roller module, a cooling device, a second guide roller, a third guide roller, a winding mechanism, a base belt and a polymer material. Theroll outlet mechanism is connected with the first guide roller; the heating roller is positioned above the first guide roller; the first guide roller is connected with the fixed mold roller; the swing pressure roller module is positioned under the fixed mold roller, and can swing around the fixed mold roller; the cooling device is positioned behind the fixed mold roller; the fixed mold roller isconnected with the second guide roller; the second guide roller is connected with the third guide roller; and the third guide roller is connected with the winding roller. A fixed pressure roller is improved as a swing pressure module, so that the defect of the fixed roller only pressing a fixed position is made up, and the embossing precision and the embossing efficiency are greatly improved.

Owner:JIMEI UNIV

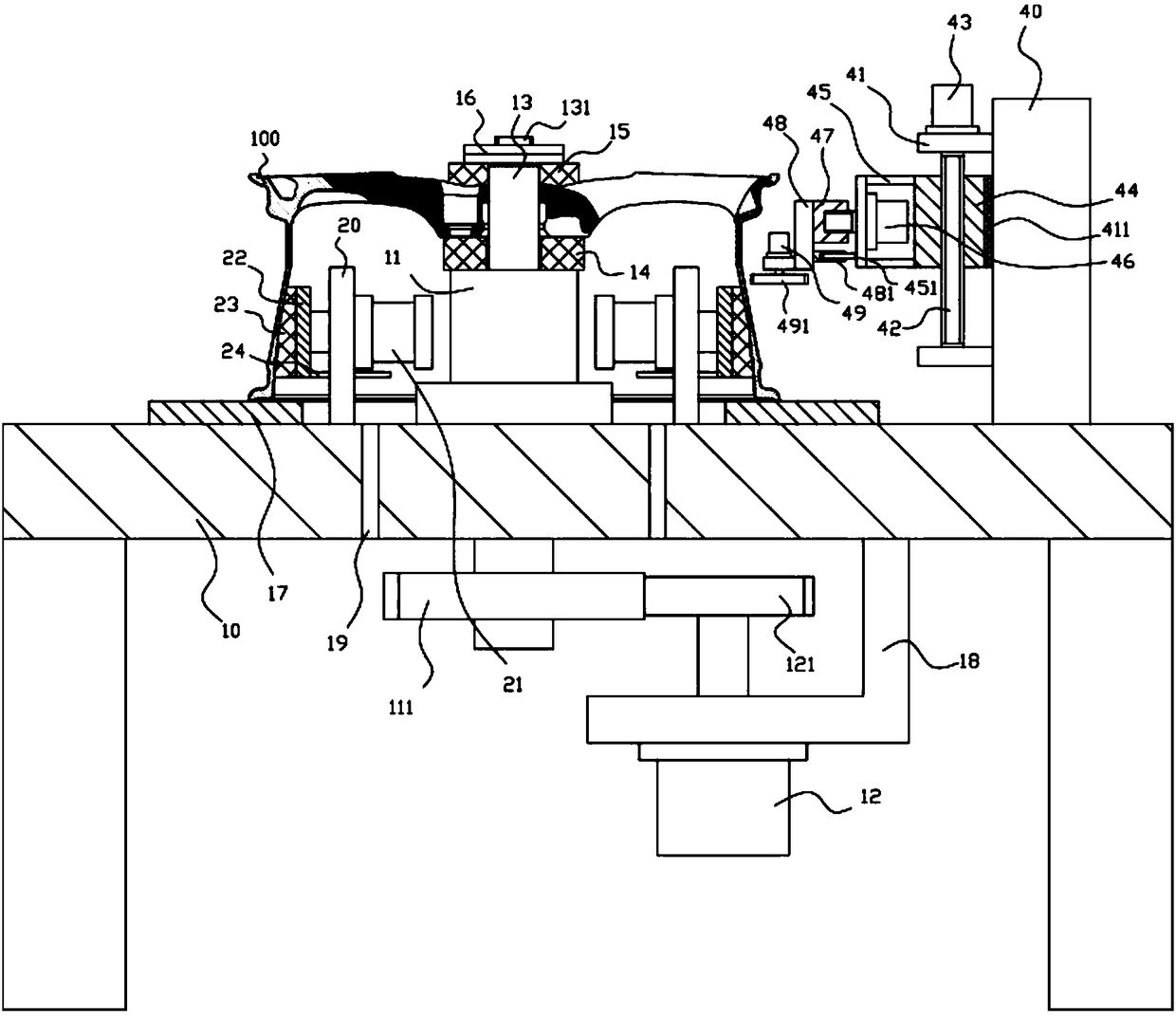

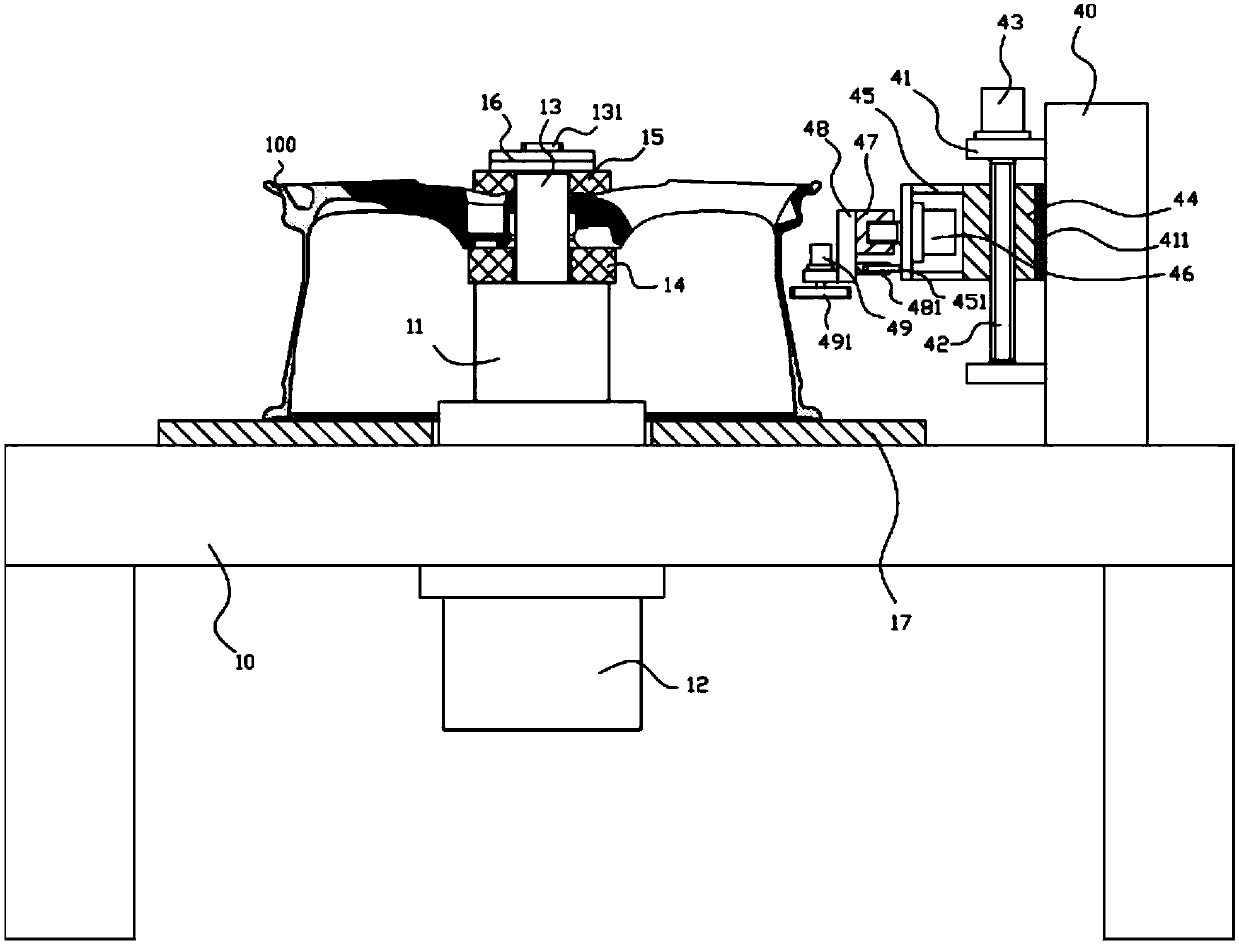

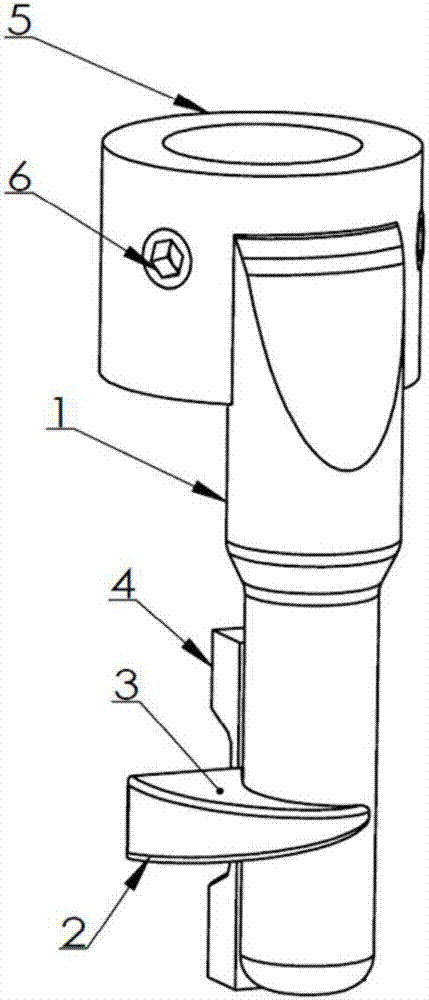

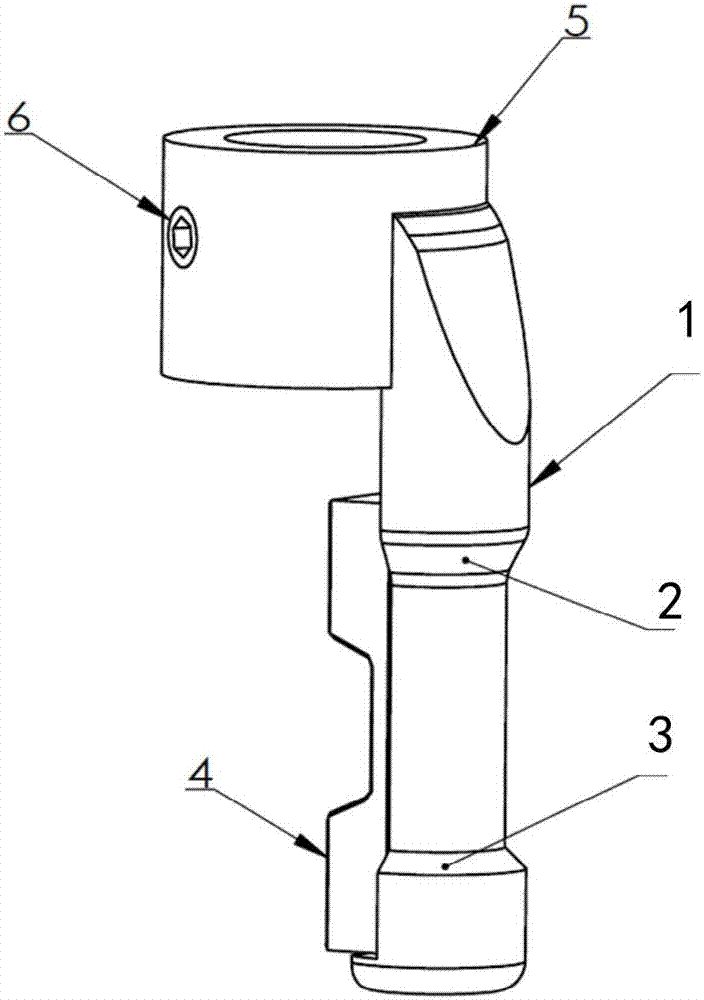

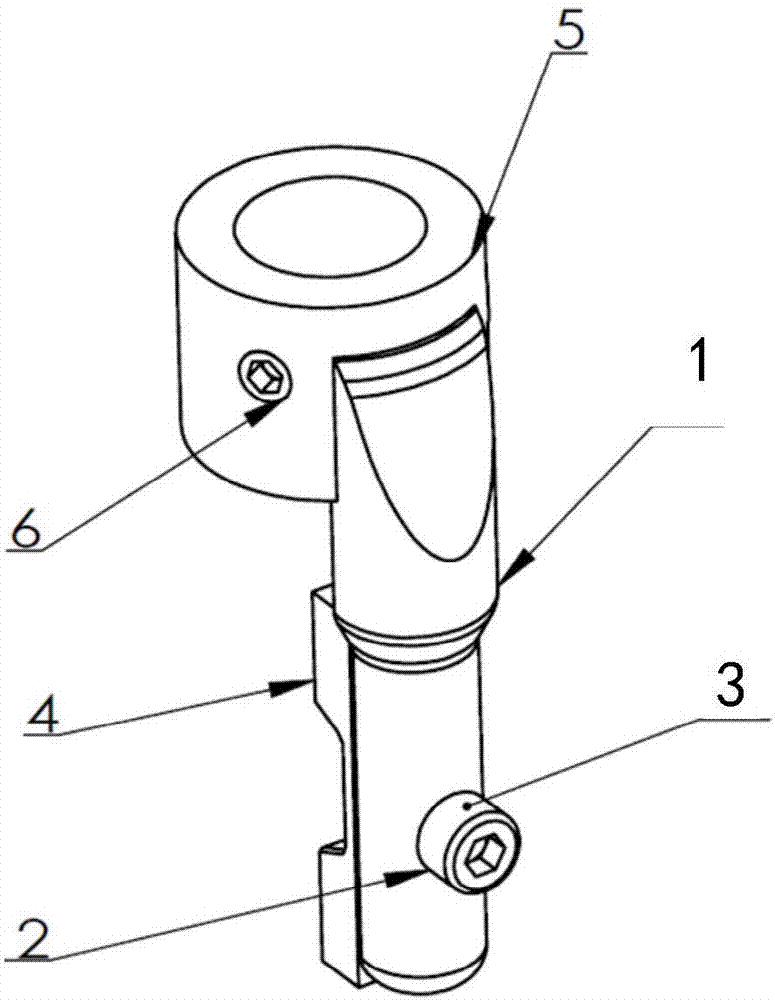

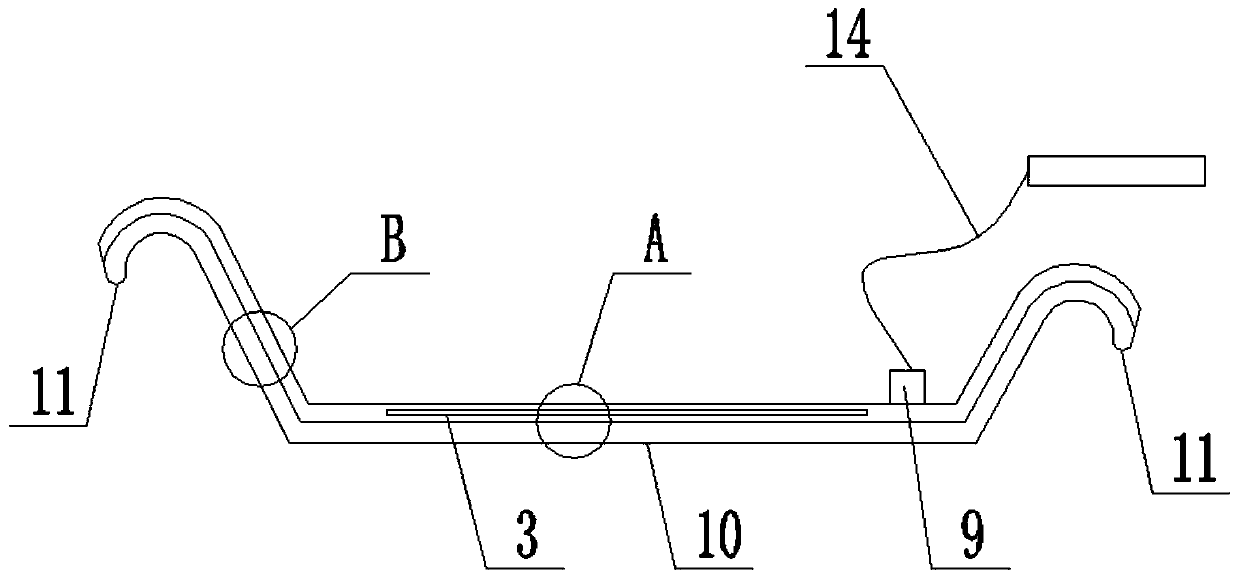

Tire mounting and dismounting head and tire mounting and dismounting machine

The embodiments of the invention provide a tire mounting and dismounting head and a tire mounting and dismounting machine. The tire mounting and dismounting head comprises a fixed portion, a working portion, a connecting portion arranged on the fixed portion, and a positioning portion arranged on the working portion, wherein the fixed portion is connected with the tire mounting and dismounting machine through the connecting portion; one end of the working portion is connected to the side wall of the fixed portion; a tire mounting surface and a tire dismounting surface are also arranged at a position, matched with the positioning portion, on the working portion. The fixed portion of the tire mounting and dismounting head is connected to a main shaft of the tire mounting and dismounting machine, a tire is placed on the tire mounting and dismounting machine, a rim is matched with the positioning portion, a tire bead is raised to the tire dismounting surface, and the main shaft rotates to make the tire disassembled from the rim so as to complete tire dismounting; the tire is re-placed on the rim, the tire bead is attached to the tire dismounting surface, and the main shaft rotates to make the tire assembled on the rim so as to complete tire mounting. The tire mounting and dismounting head is small in size and simple in structure, the tire bead is low in deformation during tire mounting and dismounting, and tire bead rubber is not easily damaged; meanwhile, the usage range is wide, and the tire of a motor vehicle can be mounted and dismounted.

Owner:CORWEI YINGKOU IND CO LTD

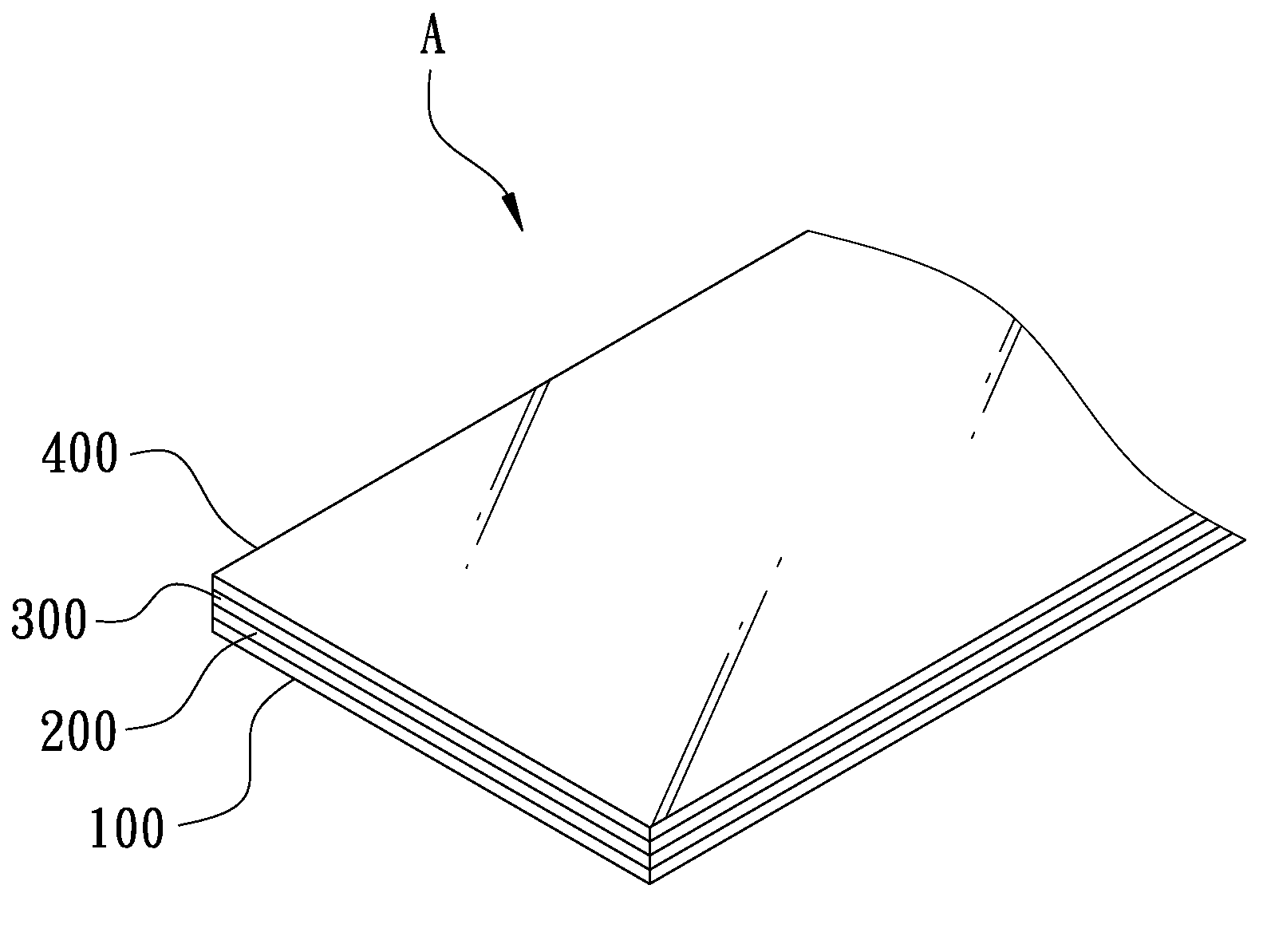

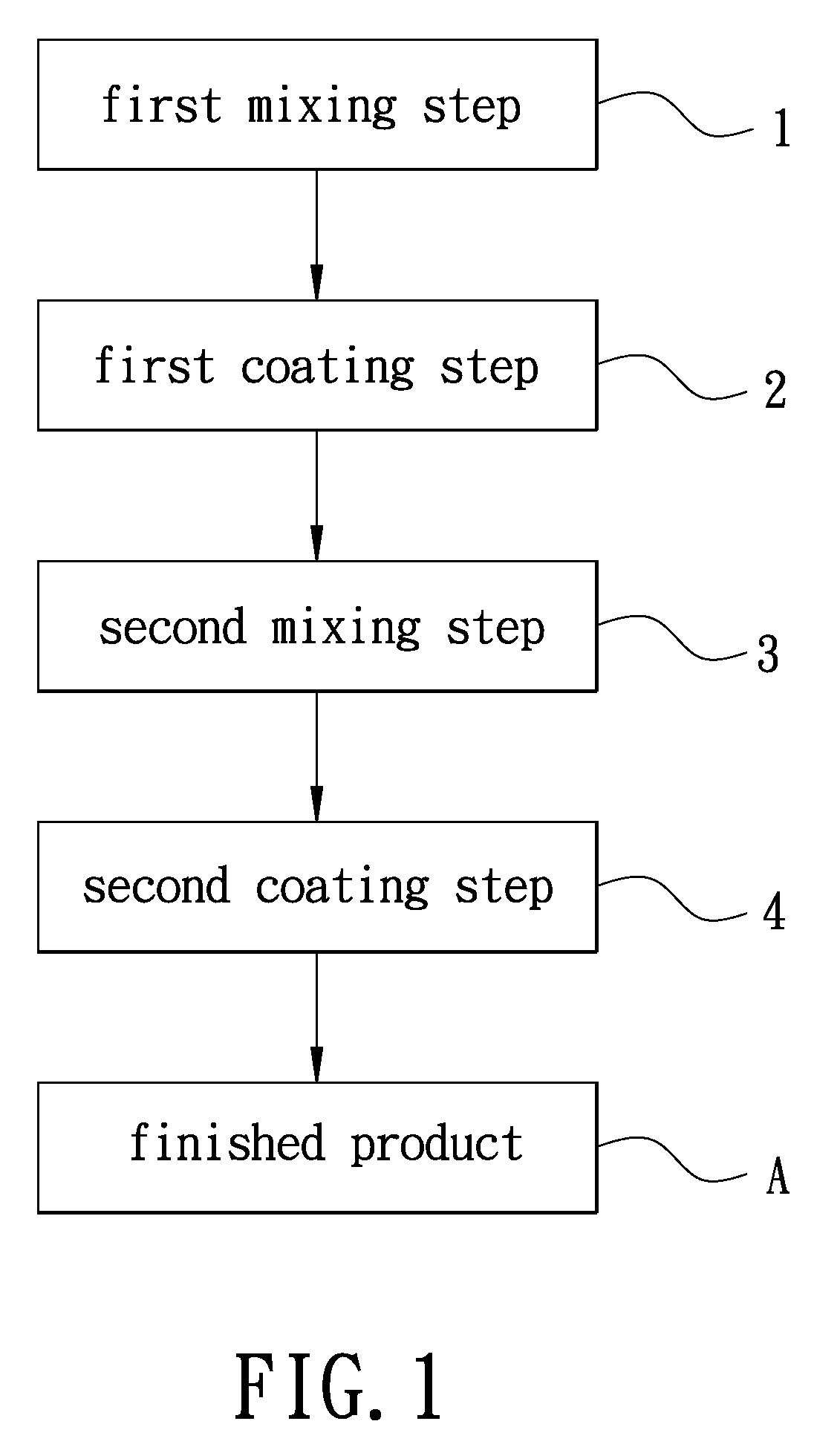

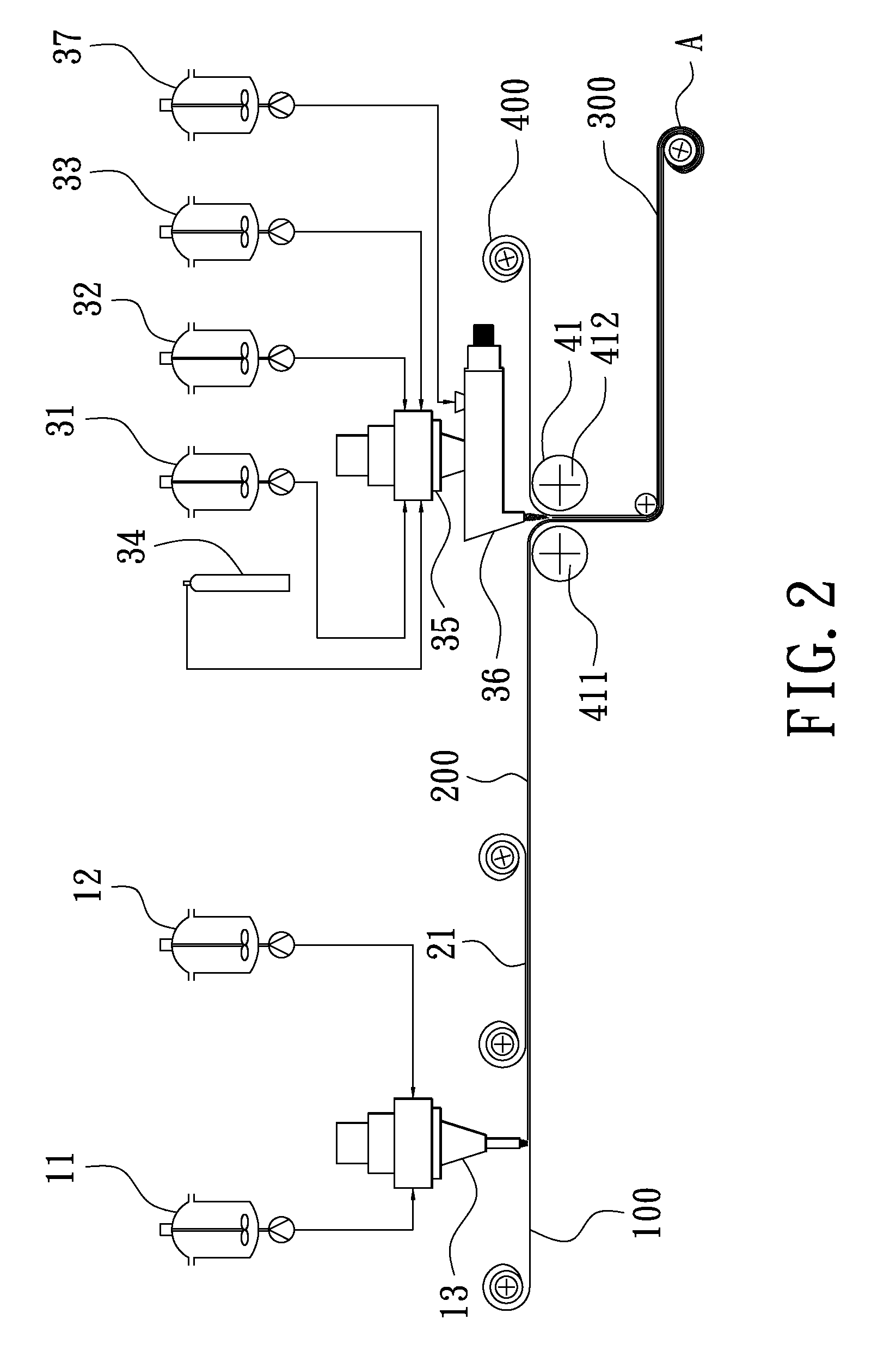

Method of manufacturing an adhesive material that can be printed and repeatedly stuck and torn

InactiveUS20100215850A1Not easily damagedNot easy to damageStampsPolyureas/polyurethane adhesivesIsocyanateChemistry

A method of manufacturing an adhesive material that can be printed and repeatedly stuck and torn including a first mixing step in which a first material of isocyanate polymer containing NCO is mixed with a second material of hydroxy compound containing OH into a first mixture; a first coating step in which the first mixture is coated on a substrate to form an adhesive layer; a second mixing step in which at least the first material, the second material, and a fiber material are mixed into a second mixture, and a second coating step in which the second mixture is coated on the adhesive layer to form a printing layer, a finished product being formed. A pattern or character can be printed on the printing layer, and the printing layer is pasted on a determined site for repeated paste and tear. The product is preferably resilient and not easily damaged.

Owner:CHOU LUNG WEN

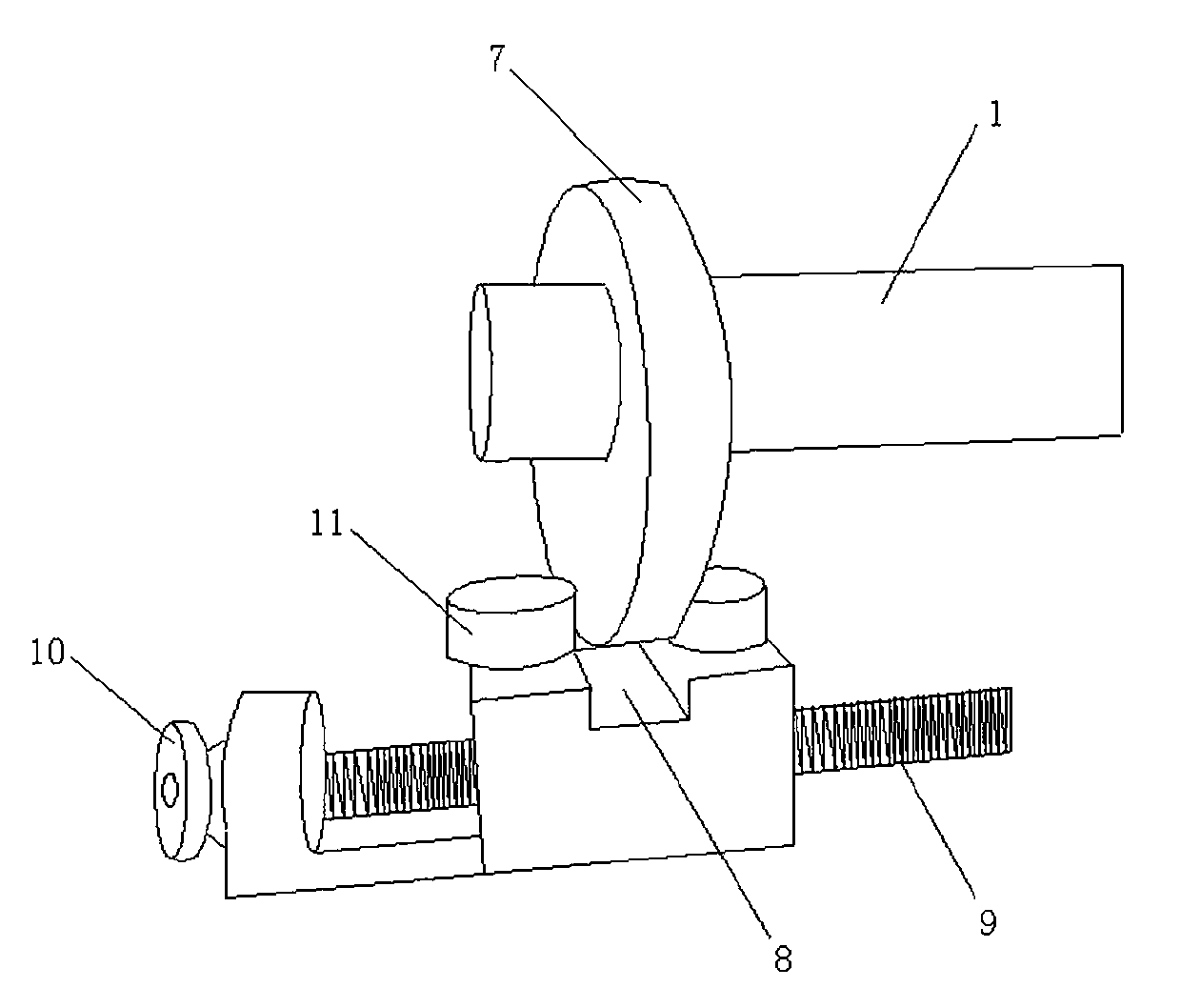

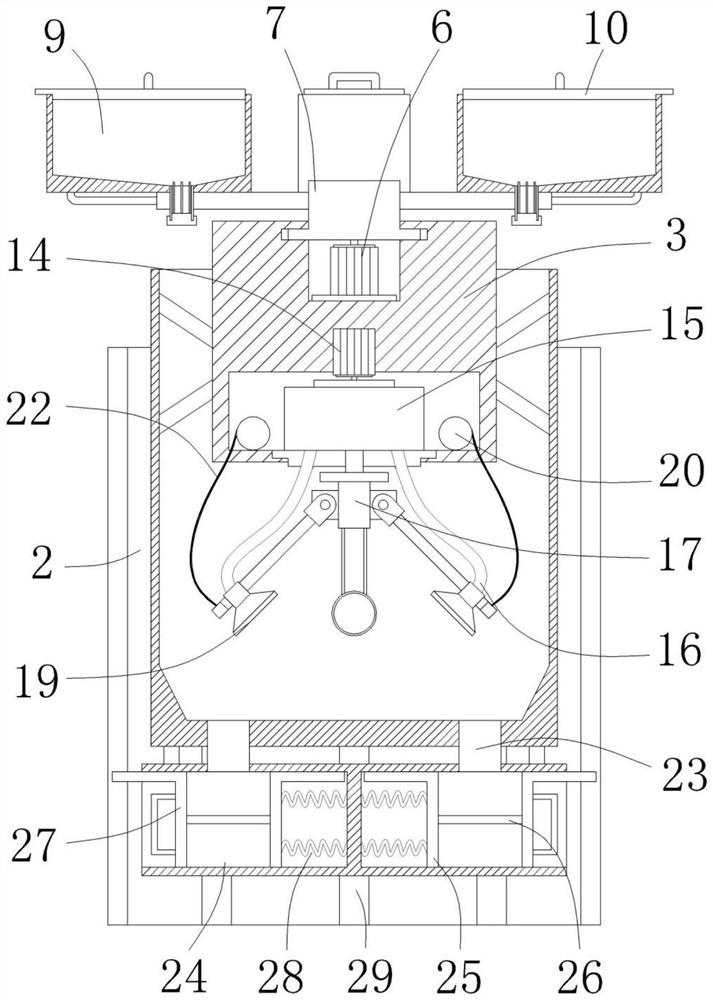

Liftable oil barrel mechanism for oil immersion of parts

InactiveCN107803306AEasy to place manuallyNot easily damagedLiquid surface applicatorsCoatingsOil immersionMotherboard

The invention discloses a liftable oil drum mechanism for oil immersion of components, which comprises a frame, vertical main boards are fixed on both sides of the top surface of the top plate of the frame, and horizontal plates are fixed on the top side walls of the vertical main board , the lifting motor is fixed on the top surface of the horizontal plate, the bottom end of the vertical lifting screw is hinged on the top plate of the frame, the top end of the vertical lifting screw is hinged on the horizontal plate, the output shaft of the lifting motor is a spline shaft, and the spline shaft The key shaft is inserted into the spline hole at the top of the vertical lifting screw, and the lifting plate is screwed into the two vertical lifting screws. The middle part of the lifting plate has a central through hole, and the oil drum is inserted into the central through hole. The bottom surface of the oil barrel is pressed against the top plate of the frame, the upper outer wall of the oil barrel is fixed with a limit block, and the limit block is pressed against the top surface of the lifting plate; it can lift the oil barrel according to needs, which is convenient for manual placement, and at the same time , the buffer spring it has can ensure that the metal products put in are slowly immersed in the oil, not easy to be damaged, and the effect is good.

Owner:FOSHAN RUIPUDA OPTOELECTRONICS TECH CO LTD

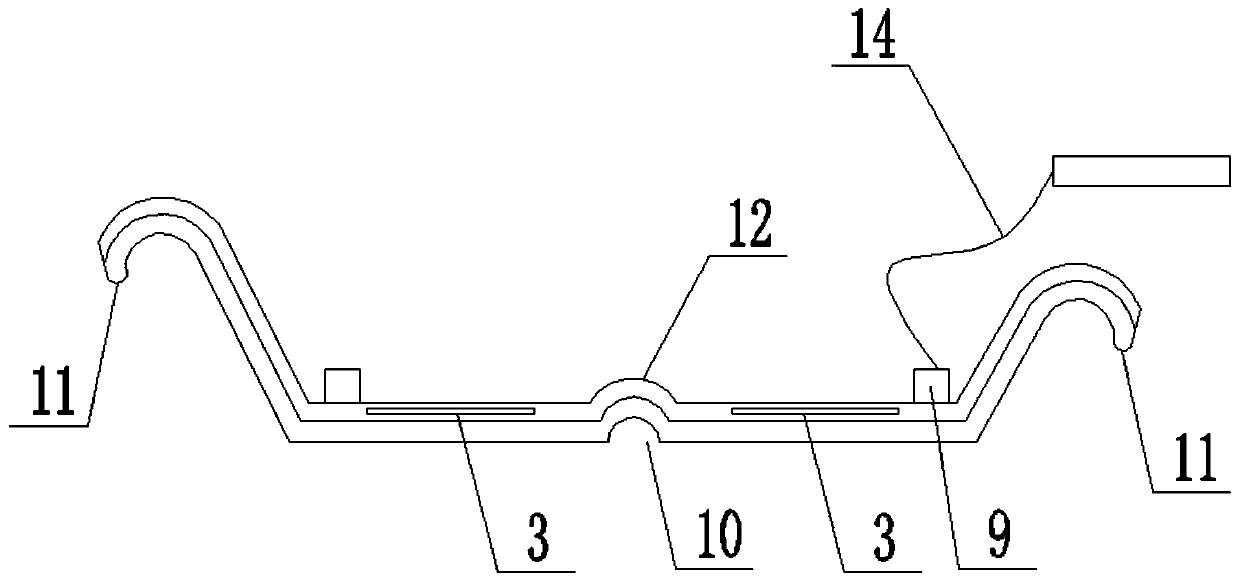

Integrated photovoltaic tile

InactiveCN109831147AThe overall structure is simple and reasonableNot easily damagedPhotovoltaic supportsRoof covering using slabs/sheetsCell layerEngineering

The invention discloses an integrated photovoltaic tile. A traditional photovoltaic tile structure used in a building is complex in structure so as to result in heavy weight, inconvenient transportation, complicated installation steps and high maintenance cost. The integrated photovoltaic tile comprises a front film layer, a first adhesive film layer, a photovoltaic cell layer, a second adhesive film layer, a back film layer and / or a tile base layer which are integrally formed. The integrated photovoltaic tile has the dual functions of photovoltaic power generation and building tile. The shapeof the integrated photovoltaic tile is specifically defined according to the requirements of a specific applicable occasion, and is light in weight, convenient to install, and stable in use performance. The integrated photovoltaic tile is used in the field of construction.

Owner:武汉美格科技股份有限公司

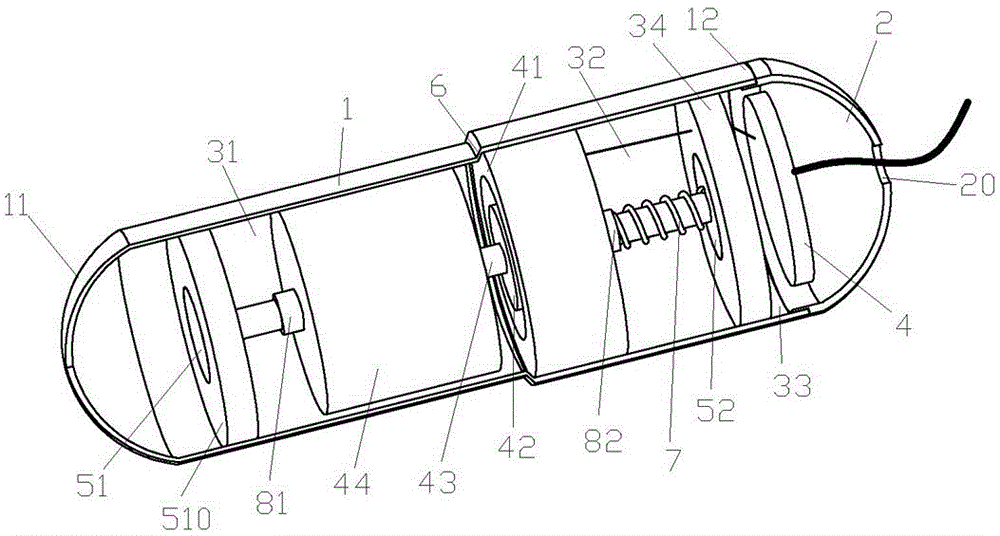

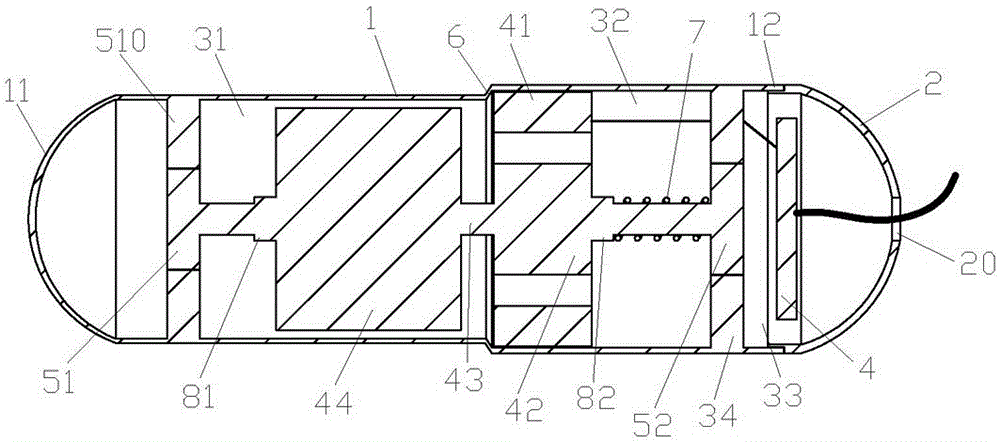

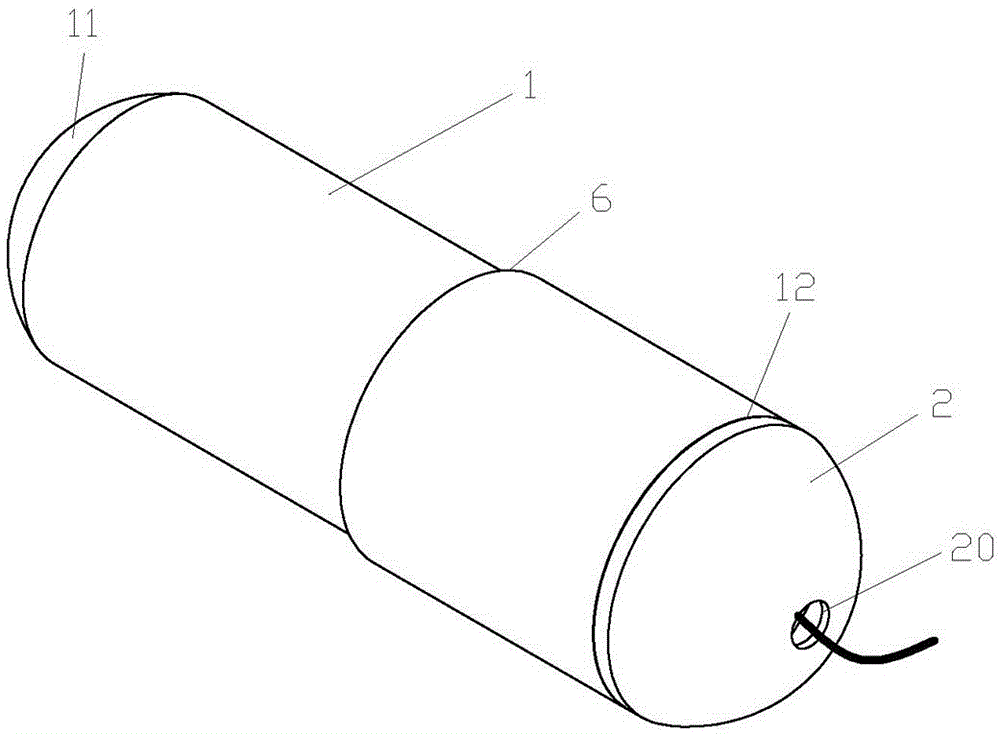

Micro gyromagnetic device structure

ActiveCN105148407AImprove stabilityNot easily damagedMagnetotherapy using variable magnetic fieldsStructural engineeringElectrical and Electronics engineering

The invention relates to the technical field of magnetic health care articles and specifically to a micro gyromagnetic device structure. The micro gyromagnetic device structure comprises an outer cover pipe. One end of the outer cover pipe is a sealed end and the other end of the outer cover pipe is an opening end. The opening of the opening end is equipped with an end cover. A rotary acting chamber, a positioning chamber, and an external connection chamber are successively arranged in the outer cover pipe from the sealed end to the opening end. The rotary acting chamber is communicated with the positioning chamber. A spacing board is fixed to the inner wall of the outer cover pipe and arranged between the positioning chamber and the external connection chamber. The position, located at the external connection chamber, of the outer cover pipe and the end cover define a storage space in which a driving circuit board can be placed. A stator coil is disposed in the positioning chamber. A rotor core is arranged in an area surrounded by the inner loop of the stator coil and is fixed to a rotating shaft. The rotating shaft is arranged along the axial direction of the outer cover pipe and passes by the rotary acting chamber and the positioning chamber. A magnet in the area of the rotary acting chamber is fixed to the rotating shaft. The micro gyromagnetic device structure is high in stability, good in magnetic health care effect, and high in comfortableness.

Owner:HEYE HEALTH TECH CO LTD

Automobile surface protection film

The invention discloses an automobile surface protection film. The formula of the automobile surface protection film comprises the following raw materials in parts by weight: 40 to 60 parts of polyethylene high-molecular polymer, 20 to 30 parts of acrylic ester polymer, 20 to 30 parts of trimethylolpropane triacrylate, 8 to 12 parts of oil soluble initiator, 8 to 12 parts of stabilization additive, 8 to 12 parts of antioxidant, 10 to 14 parts of electrostatic master batch, 4 to 8 parts of polyethylene wax, 4 to 8 parts of oleamide, 4 to 8 parts of containing hydrogen silicone oil, 2 to 4 partsof inhibitor, 2 to 4 parts of catalyst and 2 to 4 parts of surfactant. According to the automobile surface protection film prepared from the invention, the oil resistance and the water resistance ofan automobile surface can be improved, the protection film is unlikely to be damaged, and in addition, impurities attached to the surface of the protection film can be extremely easily cleaned.

Owner:重庆友拓汽车零部件有限公司

Anti-damage health-preserving tea ingredient mixing device

The invention discloses an anti-damage health-preserving tea ingredient mixing device which comprises a shell, a side plate located on the rear side of the shell and a supporting rod fixed to the lower surface of the shell, a base is arranged in the top end of the shell, fixing plates are fixed to the surfaces of the front end and the rear end of the base, and a first driving motor is fixed to the interior of the top end of the base. a feeding mechanism is arranged above the first driving motor, a second driving motor is fixed in the bottom end of the base, a mixing mechanism is arranged below the second driving motor, the lower surface of the shell is communicated with a discharging pipe, the bottom end of the discharging pipe is communicated with a quantitative discharging box, and the quantitative discharging box is fixedly connected with the shell. By arranging a series of structures, ingredients can be preliminarily mixed during feeding, then the ingredients are mixed again under the action of wind power, the ingredients cannot be damaged under the condition that sufficient mixing is guaranteed, and quantitative discharging can be achieved during discharging.

Owner:靖州飞山茶业有限公司

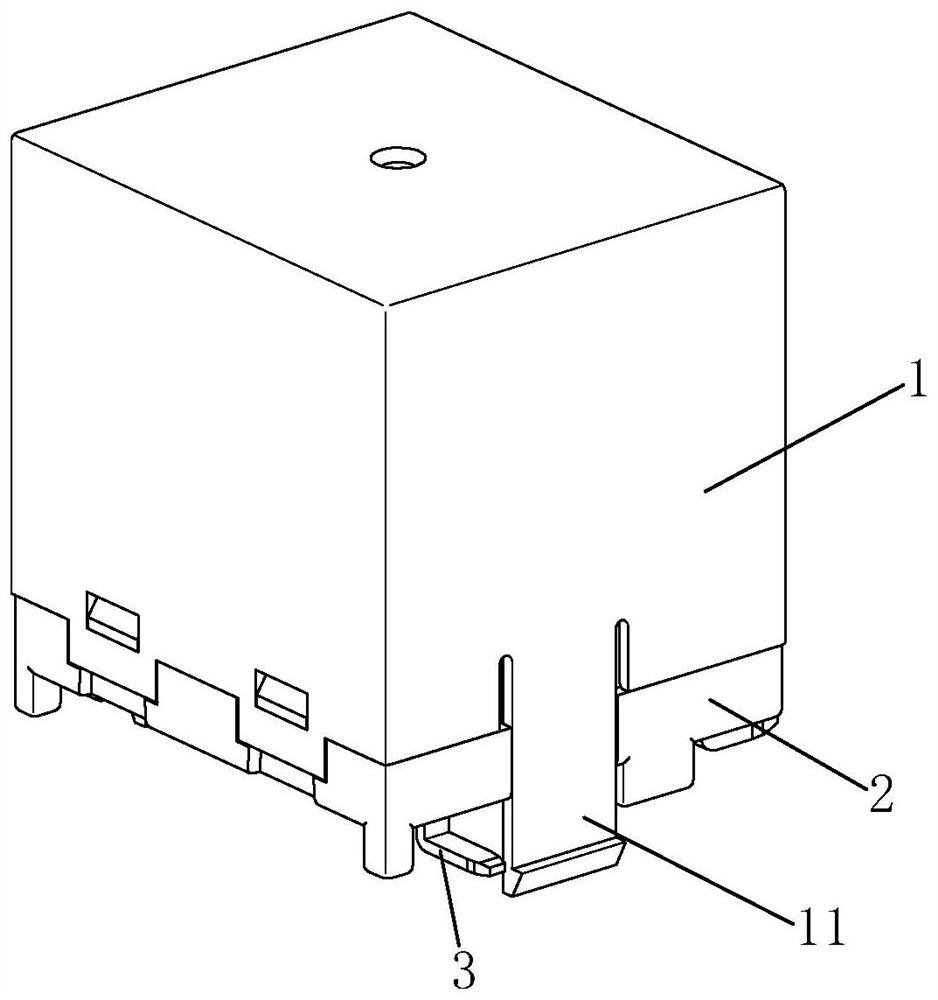

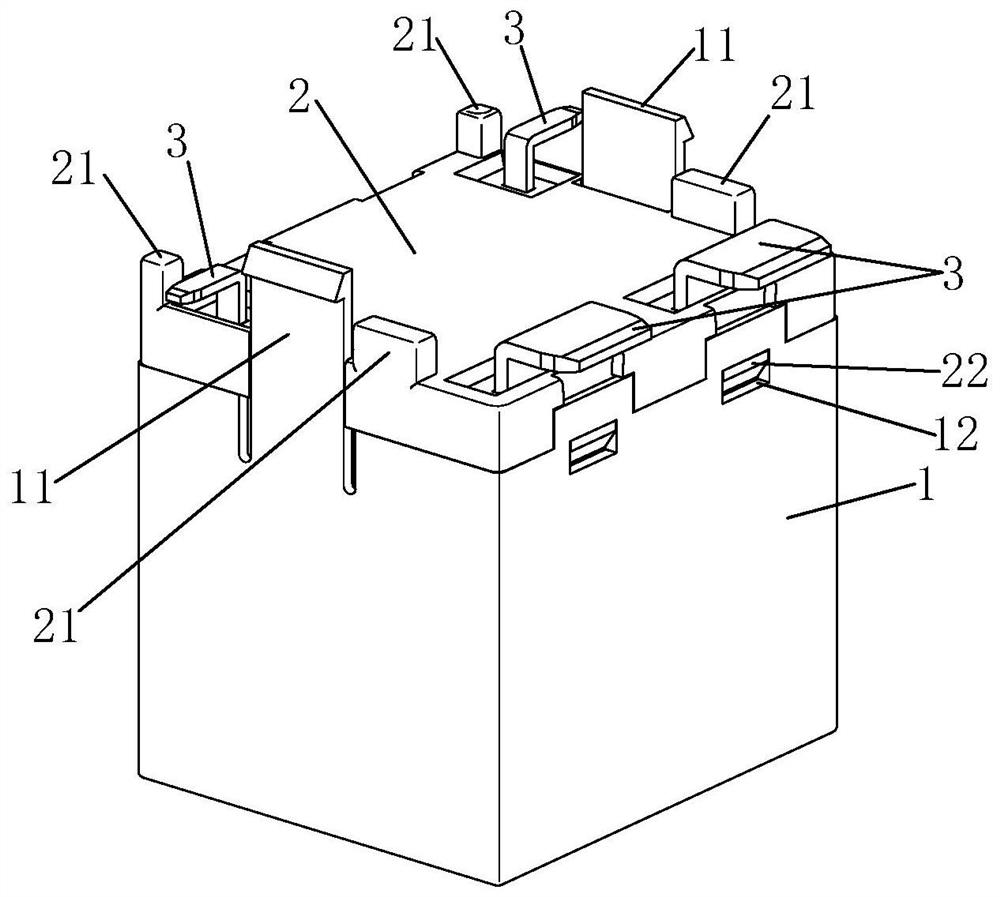

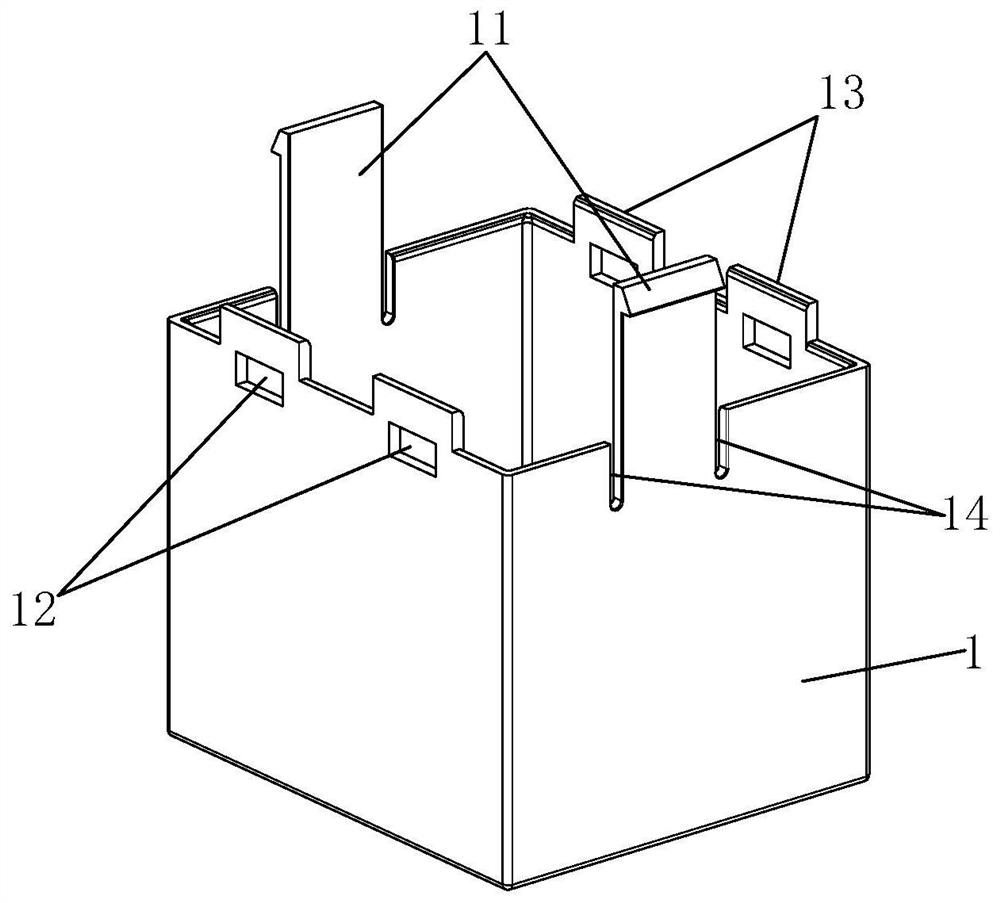

Electromagnetic relay with clamping structure

PendingCN112509868ANot easily damagedImprove flexibilityElectromagnetic relay detailsStructural engineeringSurface mounting

The invention discloses an electromagnetic relay with a clamping structure. The relay comprises a relay body, wherein the bottom of the relay body is provided with a plurality of lead-out pins which can be surface-mounted on a PCB or a substrate, the bottom of the relay body is provided with a plurality of buckles, and each buckle is used for being clamped on the PCB or the substrate. According tothe invention, before surface mounting of each lead-out pin, each buckle can be clamped on a PCB or a substrate in advance to achieve a pre-positioning effect, so that in the subsequent surface mounting process, the relay is prevented from tilting, sliding and the like, good welding of the lead-out pins is ensured, and under the positioning of each buckle, when the relay is under the action of external force, the welding parts of the lead-out pins are not easy to damage.

Owner:XIAMEN HONGFA ELECTROACOUSTIC CO LTD

Method for preparing plastic runway material

The invention relates to a method for preparing a plastic runway material and mainly aims to solve the problem that existing plastic runways are easy to damage and age. The material is prepared from the following raw materials in parts by weight: 42 parts of ethylene propylene diene monomer rubber, 26 parts of nitrile rubber, 7 parts of neoprene, 9 parts of silicon carbide, 12 parts of sodium silicate and 4 parts of methyl isobutyl ketone. The material has the advantages of being not easy to damage, good in strength and good in aging resistance.

Owner:张一男

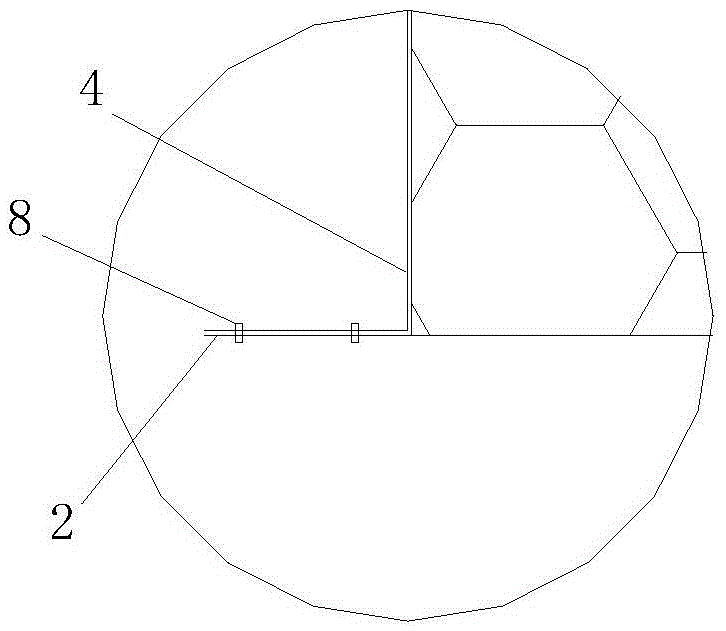

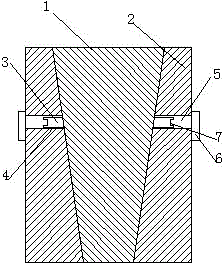

Novel ventilation brick

The invention relates to a novel ventilation brick. The novel ventilation brick comprises a ventilation brick core (1), and a ventilation brick base brick (2) arranged at the external of the ventilation brick core (1); elastic stoppers (3) are symmetrically arranged at the side part of the ventilation brick core (1); and positioning holes (4) for extending in the elastic stoppers (4) are formed in the corresponding parts of the ventilation brick base brick (2). The novel ventilation brick is provided with the elastic stopper; the elastic stoppers are extruded in the assembly process; the ventilation brick core can be conveniently assembled in the ventilation brick base brick only by overcoming the elastic force; as the elastic stoppers with the structure are only suffered from the extruding force, the elastic stoppers are not easy to damage; once the elastic stoppers enter the positioning holes, the elastic stoppers are turned due to disappearing of external force, that is, the assembly is finished; and due to existent of the elastic stoppers, the position of the ventilation brick core is fixed without generating the loosening phenomenon.

Owner:JIANGSU YUEZHAN NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com