Umbrella type drying equipment for glass test tubes

A drying equipment and drying technology, applied in drying chamber/container, drying gas arrangement, local stirring dryer, etc., to achieve the effect of improving drying efficiency and being less prone to damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

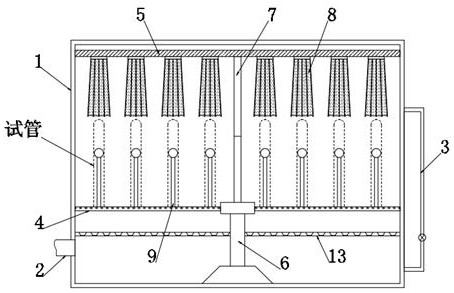

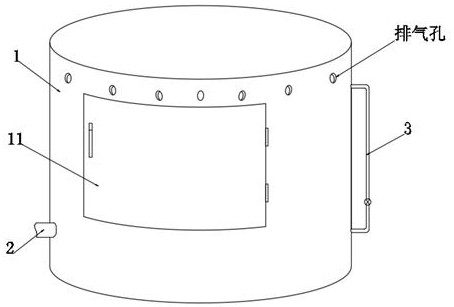

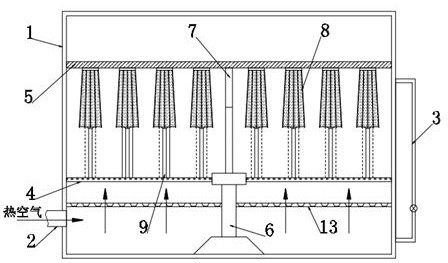

[0042] see Figure 1-2 , a glass test tube umbrella type drying equipment, comprising a drying shell 1, the lower left end of the drying shell 1 is fixedly connected with a vent pipe 2, the vent pipe 2 communicates with the drying shell 1, and the inside of the drying shell 1 is fixedly connected with a porous air plate 13, and the porous air The plate 13 is located above the ventilation pipe 2. After the hot air is passed into the drying shell 1 from the ventilation pipe 2, it needs to move upward along the pores on the porous air plate 13, thereby forming a hot air flow from bottom to top, and controlling the flow of hot air. The temperature is 35-50°C, which is convenient for the air-expanding umbrella 8 to expand outwards. The outer end of the drying shell 1 is connected with a sealed door 11. The transverse span of the sealed door 11 is not less than 1 / 3 of the diameter of the drying shell 1, which is convenient for placing the test tube in the The operation on the inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com