Guiding component, wood floor storage and supply device and wood floor paving robot

A technology for supplying devices and guides, which is applied to buildings, building structures, etc., can solve problems such as difficulty in controlling the falling speed, and achieve the effects of controllable conveying speed, stable operation and small impact force.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

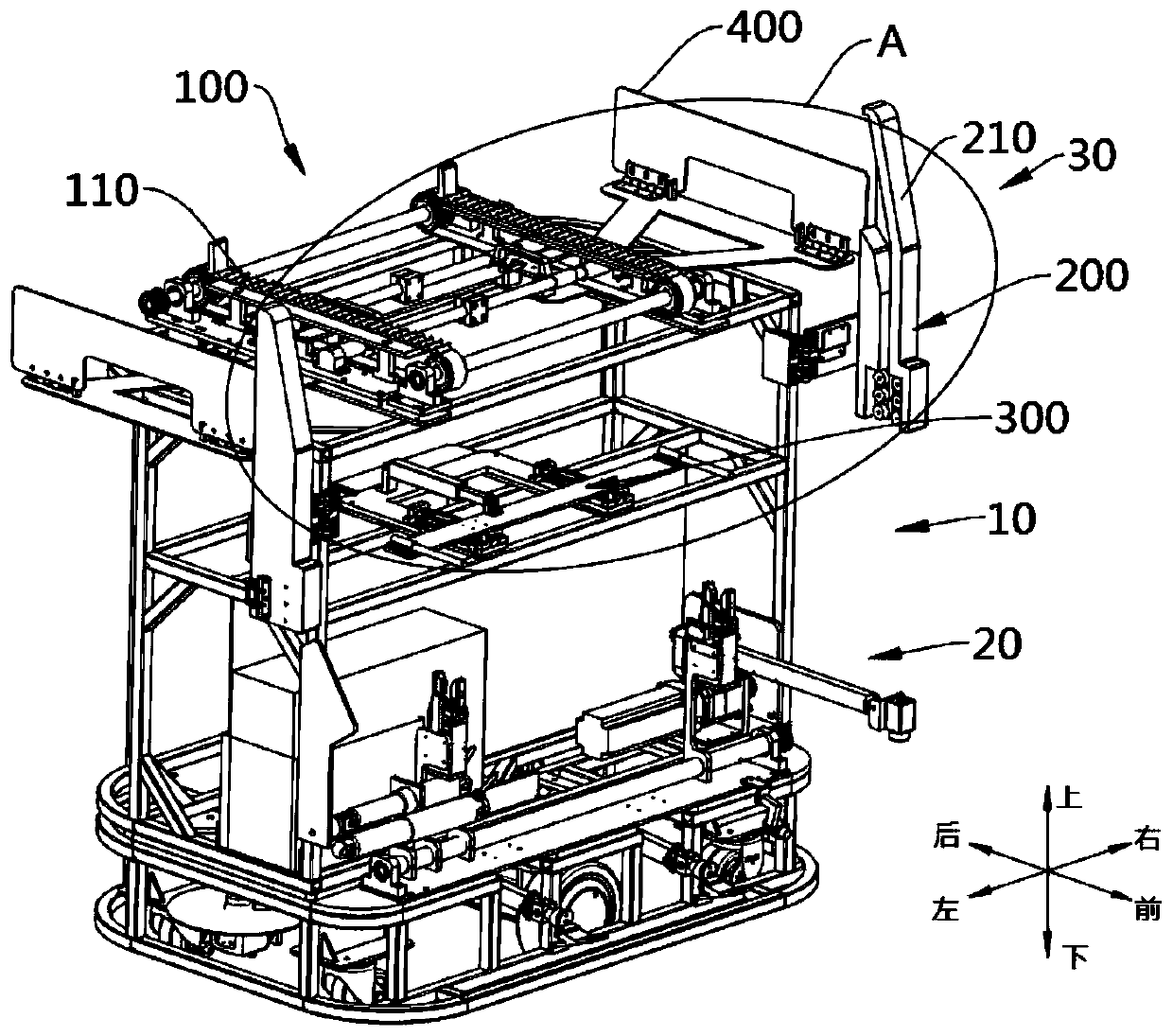

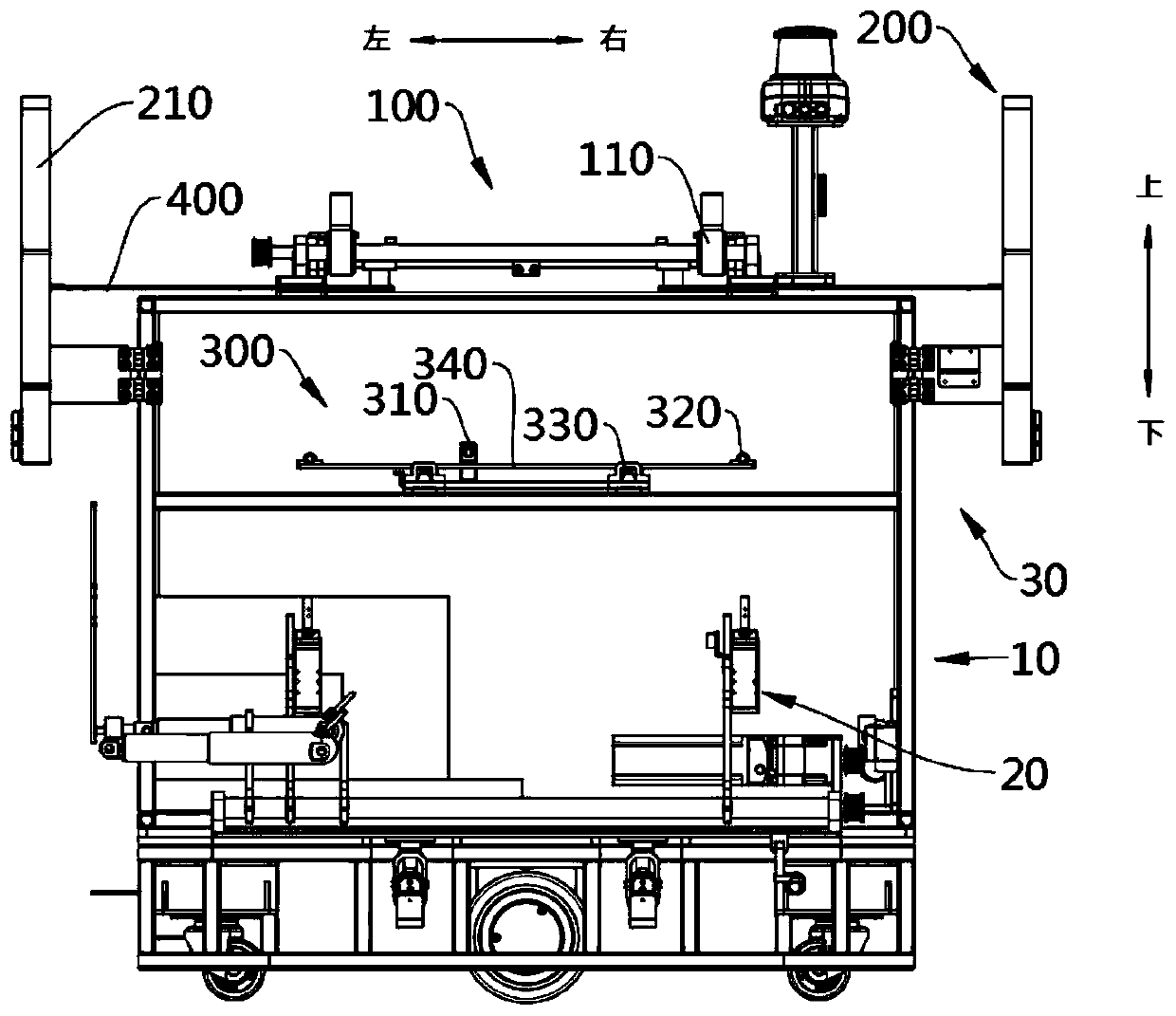

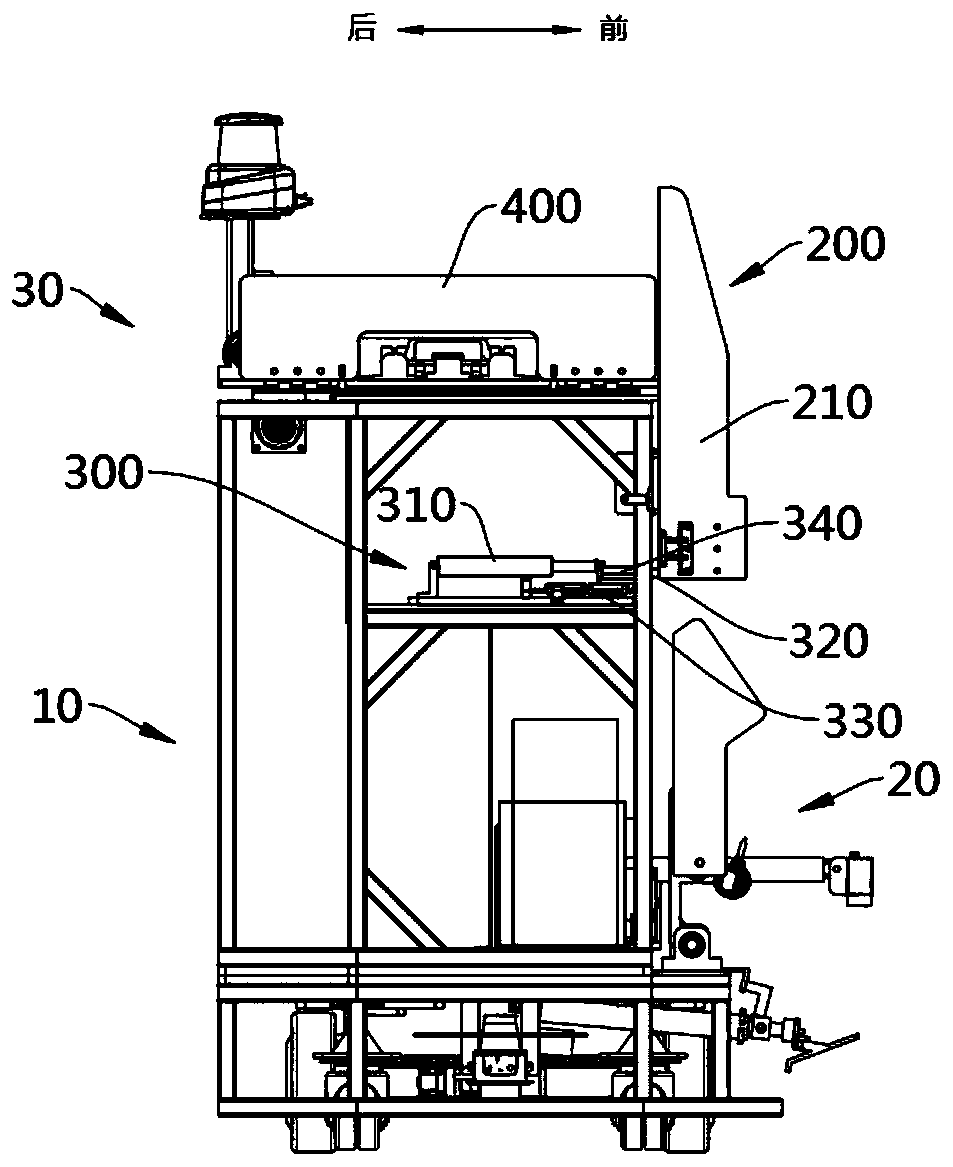

[0047] The embodiment of the present application provides a wooden floor laying robot, which is used to temporarily store the wooden floor to be laid, and install the temporarily stored wooden floor to the wooden floor that has been laid. The floor is installed on the ground and spliced with the already laid wooden floor.

[0048] The wooden floor laying robot includes a wooden floor laying device 20 and a wooden floor storage supply device 30. The wooden floor storage supply device 30 can temporarily store the wooden floors to be laid, and guide the wooden floors to be laid one by one. The wooden floor laying device 20, the wooden floor laying device 20 installs the acquired wooden floor to be laid on the ground.

[0049] figure 1 A schematic diagram of the three-dimensional structure of the wooden floor laying robot is shown, figure 2 , image 3 , Figure 4 A schematic diagram of the planar structure of the wooden floor laying robot under different viewing angles is s...

Embodiment 2

[0089] On the basis of Embodiment 1, this embodiment provides a guide member 210, the buffer structure 230 of which includes a fixed seat 235, a mounting plate 232 and a spring 234, the fixed seat 235 can be an integrally formed bump on the guide member 210, or It may be a protrusion fixedly installed on the guide piece 210 . Among the two groups of clamping rollers 231 of the buffer structure 230 , one group is installed on the guide member 210 , and its position is fixed relative to the guide member 210 , and the other group is installed on the above-mentioned installation plate 232 .

[0090] Such as Figure 7 , Figure 8 with Figure 9 As shown, the guide groove 220 is opened on the first side of the guide member 210, the clamping roller 231 is located at the lower section of the guide groove 220, the fixing seat 235 and the mounting plate 232 are located on the second side, and the fixing seat 235 is fixed on the first side of the guide member 210. On two sides, one en...

Embodiment 3

[0099] On the basis of Embodiment 1, this embodiment provides a guide 210, the buffer structure 230a of the guide 210 is different from the buffer structure 230 in Embodiment 2, its structure is as follows Figure 11 , Figure 12 with Figure 13 shown.

[0100] The buffer structure 230 a includes two sets of clamping rollers 231 a , at least one set of clamping rollers 231 a can move relative to the guide member 210 .

[0101] The buffer structure 230a also includes a fixed seat 235a, a movable seat 232a and an elastic member. The fixing seat 235 a can be a protrusion integrally formed on the guide member 210 , or a protrusion fixedly installed on the guide member 210 . In this embodiment, the elastic member is made of spring, that is, Figure 12 with Figure 13 The spring 234a shown in.

[0102] In this embodiment, the number of the two groups of clamping rollers 231a is three respectively, wherein the three clamping rollers 231a of one group are fixedly installed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com