Plasma sterilization equipment for ensiling raw materials and method

A technology of plasma and sterilizing equipment, which is applied in the silage field, can solve the problems of moldy silage, temperature rise, and multiple bacteria, and achieve the effect of soft feed structure, fine adjustment, and sufficient fermentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

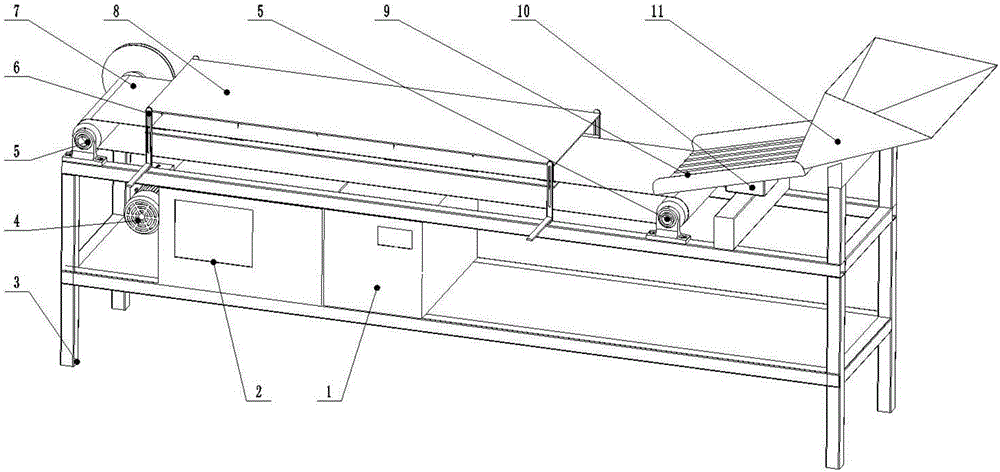

[0031] like figure 1 A plasma sterilizing device for silage raw materials is shown. The plasma generating device, the silage raw material conveying device, the high-frequency power supply control cabinet 1 and the control system control cabinet 2 are installed on the frame 3 respectively.

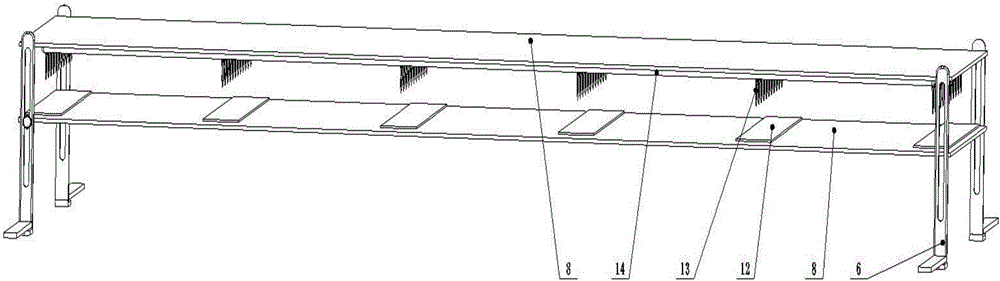

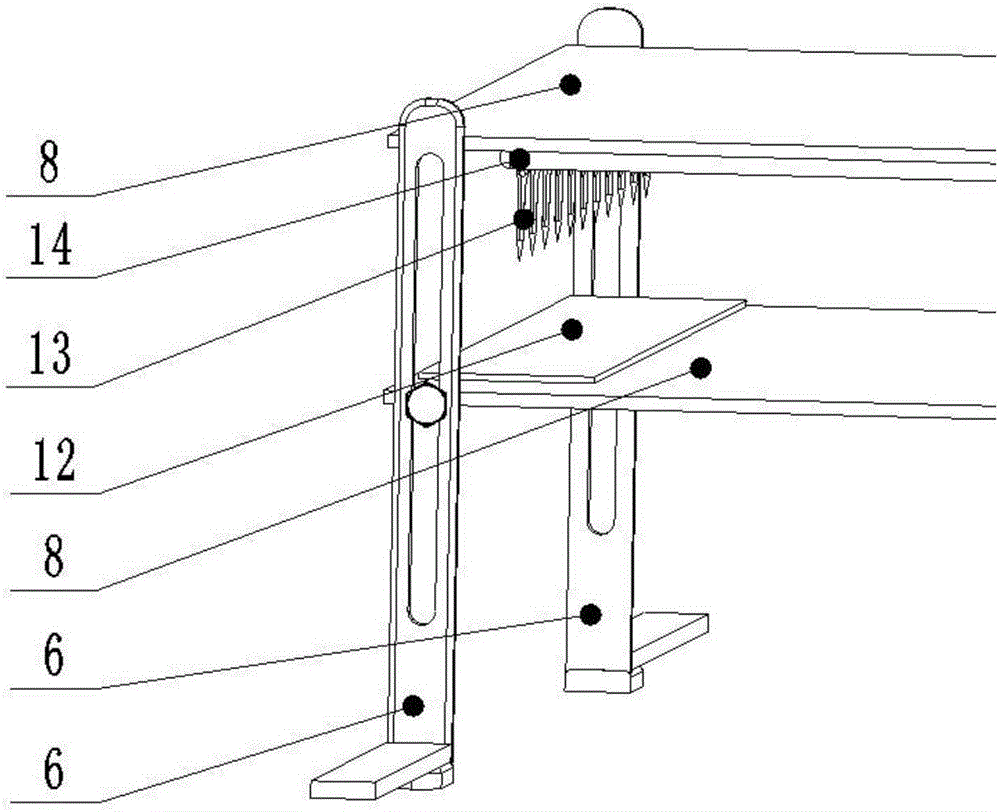

[0032] like Figure 2-Figure 3 As shown, the plasma generating device is composed of a high-frequency electrode and a ground electrode 12 .

[0033] The high-frequency electrode consists of a high-frequency electrode frame 14 and a needle electrode 13 . The high-frequency electrode frame 14 is composed of six metal beams 15 arranged in parallel between two insulating longitudinal beams. like Figure 4 As show...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com