Novel ventilation brick

A breathable brick, a new type of technology, is applied in the direction of casting melt containers, metal processing equipment, casting equipment, etc. It can solve the problems of inconvenient operation, looseness, inconvenient assembly, etc., and achieve the effect of convenient operation, not easy to be damaged, and easy to disassemble

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

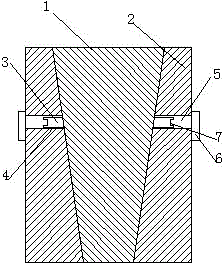

[0011] The present invention includes a breathable brick core 1 and a breathable brick seat brick 2 arranged outside the breathable brick core 1, the side of the breathable brick core 1 is provided with a symmetrically arranged elastic stopper 3, and the corresponding part of the breathable brick seat brick 2 is provided There is a positioning hole 4 for the elastic stopper 3 to extend into.

[0012] The positioning hole 4 is extended so that the air-permeable brick seat brick 2 at this position forms a through hole 5 , which is sealed by a cover plate 6 .

[0013] The outer end surface of the elastic block 3 is provided with a force receiving groove 7 .

[0014] The setting of the force receiving groove 7 of the present invention is to prevent the push rod from sliding during the force application process, so that the force is more concentrated, so that the breathable brick core 1 can slide from the positioning hole 4 with a relatively small force. out.

[0015] In order to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com