Preparation method of CrHRB400E-containing hot-rolled ribbed steel bar product

A technology for hot-rolled ribbed steel bars and products, which is applied in heat treatment equipment, heat treatment process control, temperature control, etc., can solve the problem of high production costs of hot-rolled ribbed steel bars, and achieves reduced water spraying time, high temperature after cooling, and reduced The effect of the formation of Widmandarin microstructure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] A preparation method containing CrHRB400E hot-rolled ribbed steel products, specifically comprising the following steps:

[0031] Step S1: Heat the continuous casting slab to the hot rolling temperature, carry out rough rolling, intermediate rolling and pre-finish rolling in sequence after being out of the furnace, perform pre-water cooling at a steel passing speed of 10m / s after the pre-finish rolling, and then carry out finish rolling, finish rolling Finally, the hot-rolled ribbed steel bar base material is obtained;

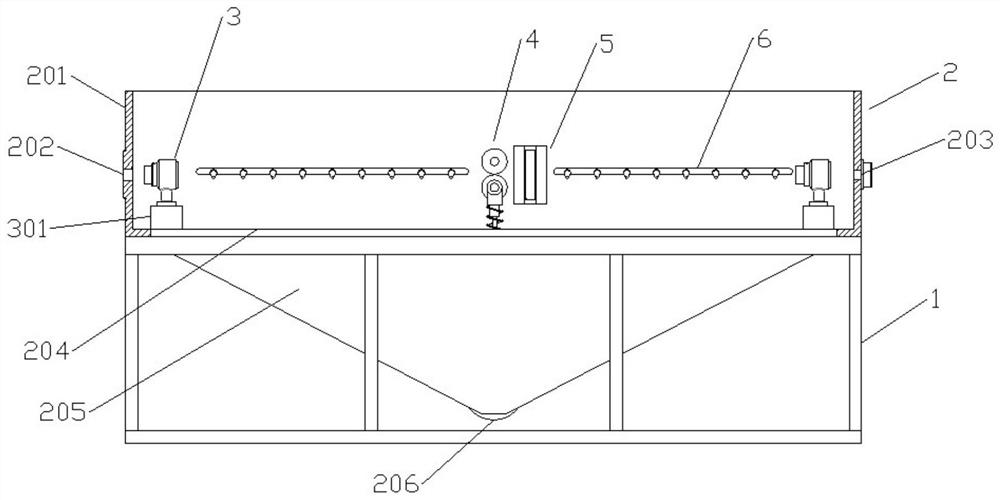

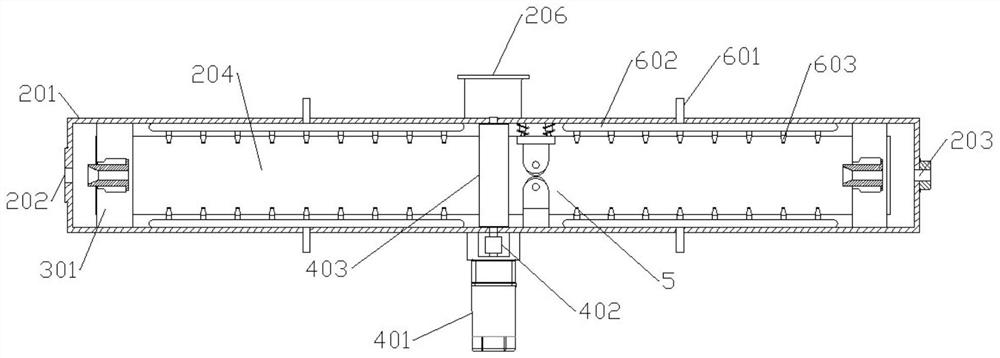

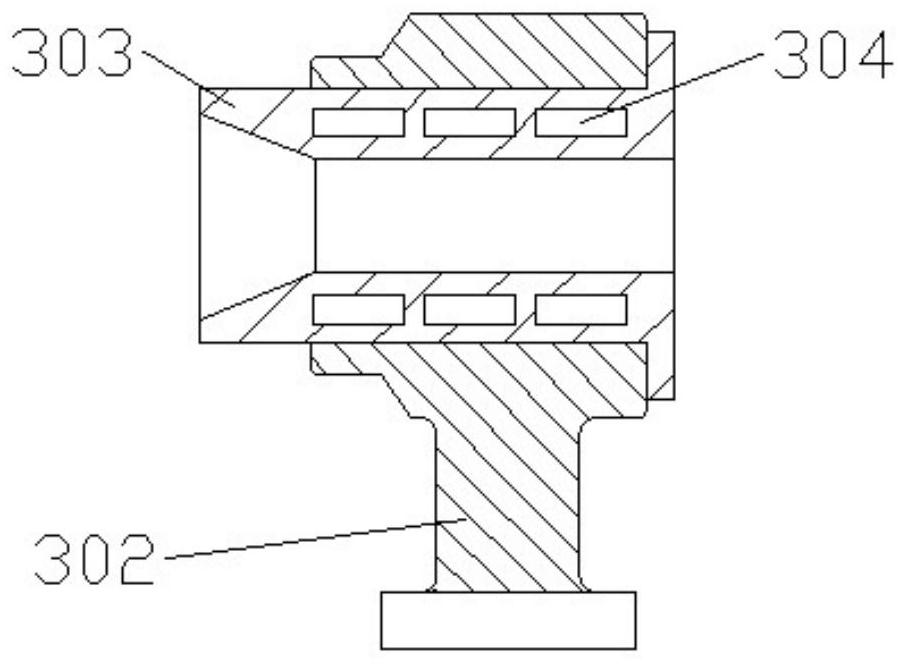

[0032] Step S2: See Figure 1-5 As shown, the hot-rolled ribbed steel bar base material is passed through the water spray cooling device, penetrated from the feed port 202, and the hot-rolled ribbed steel bar base material is passed through the temperature measuring sleeve 303 of the first temperature measuring assembly 3, Measure the temperature of the hot-rolled ribbed steel bar base material after finishing rolling, pass between two sets of water sp...

Embodiment 2

[0036] A preparation method containing CrHRB400E hot-rolled ribbed steel products, specifically comprising the following steps:

[0037] Step S1: Heat the continuous casting slab to the hot rolling temperature, and then carry out rough rolling, intermediate rolling and pre-finish rolling in sequence after the pre-finish rolling, pre-water cooling at a steel passing speed of 12m / s, and then finish rolling Finally, the hot-rolled ribbed steel bar base material is obtained;

[0038] Step S2: See Figure 1-5 As shown, the hot-rolled ribbed steel bar base material is passed through the water spray cooling device, penetrated from the feed port 202, and the hot-rolled ribbed steel bar base material is passed through the temperature measuring sleeve 303 of the first temperature measuring assembly 3, Measure the temperature of the hot-rolled ribbed steel bar base material after finishing rolling, pass between two sets of water spray cooling assemblies 6, carry out water spray cooling,...

Embodiment 3

[0042] A preparation method containing CrHRB400E hot-rolled ribbed steel products, specifically comprising the following steps:

[0043] Step S1: Heating the continuous casting slab to the hot rolling temperature, and performing rough rolling, intermediate rolling and pre-finish rolling in sequence after the pre-finish rolling, pre-water cooling at a steel passing speed of 15m / s, and then finishing rolling, Finally, the hot-rolled ribbed steel bar base material is obtained;

[0044] Step S2: See Figure 1-5 As shown, the hot-rolled ribbed steel bar base material is passed through the water spray cooling device, penetrated from the feed port 202, and the hot-rolled ribbed steel bar base material is passed through the temperature measuring sleeve 303 of the first temperature measuring assembly 3, Measure the temperature of the hot-rolled ribbed steel bar base material after finishing rolling, pass between two sets of water spray cooling assemblies 6, carry out water spray cooli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com