Composite two-stage wind power generation device in pipeline

A wind power generation device and wind power generation technology, applied in wind power generation, circuit devices, battery circuit devices, etc., can solve problems such as limiting the utilization rate of wind energy, and achieve the effects of not being easily damaged, improving utilization rate, and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

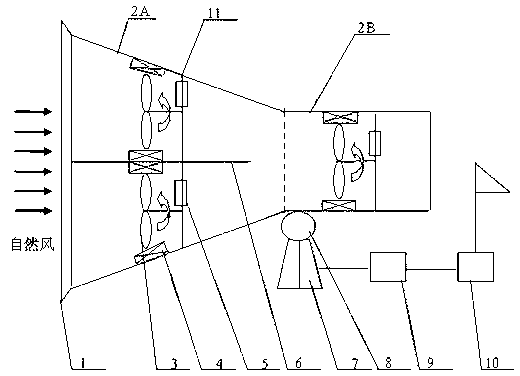

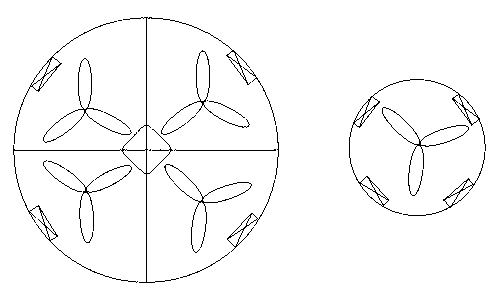

[0019] attached figure 1 Including: current collector 1, funnel pipe 2, magnetic impeller 3, induction coil and permanent magnet, wind generator 5, partition 6, stepper motor 7 assembled with support 8, control circuit 9, wind direction induction 10 and the storage battery connected with the induction coil 4 and the wind generator 5 .

[0020] The magnetically permeable impeller 3 is located in the combination formed by the connection of the funnel-type pipeline 2A and the cylindrical pipeline 2B. The magnetically permeable impeller 3 has a magnetically permeable, and is as close as possible to the induction coil and the permanent magnet 4 on the pipe wall when rotating, but There is a certain gap. Under the impact of the natural wind with a certain speed in the combination formed by entering the funnel pipe 2A and the cylindrical pipe 2B, it rotates rapidly, and the blades of each magnetically conductive impeller 3 and the permanent magnet on the pipe wall And the induction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com