Integrated photovoltaic tile

A photovoltaic tile, all-in-one technology, applied in photovoltaic modules, photovoltaic power generation, photovoltaic module support structure and other directions, can solve the problems of complex photovoltaic tile structure, cumbersome installation steps, and high maintenance costs, and achieves favorable heat dissipation and overall simple structure. And reasonable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

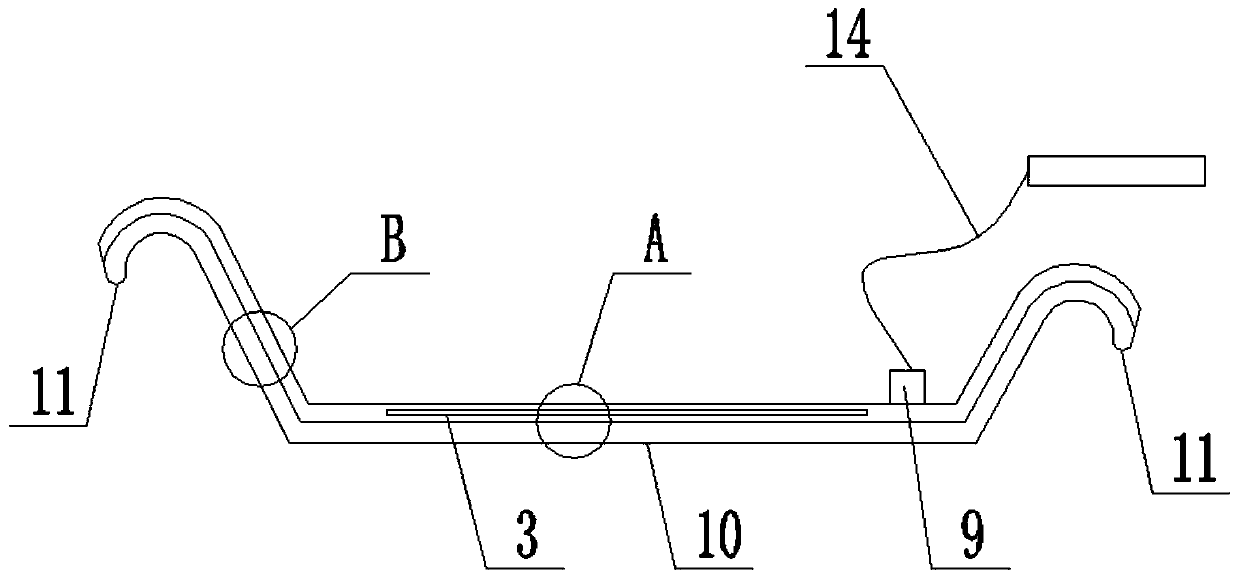

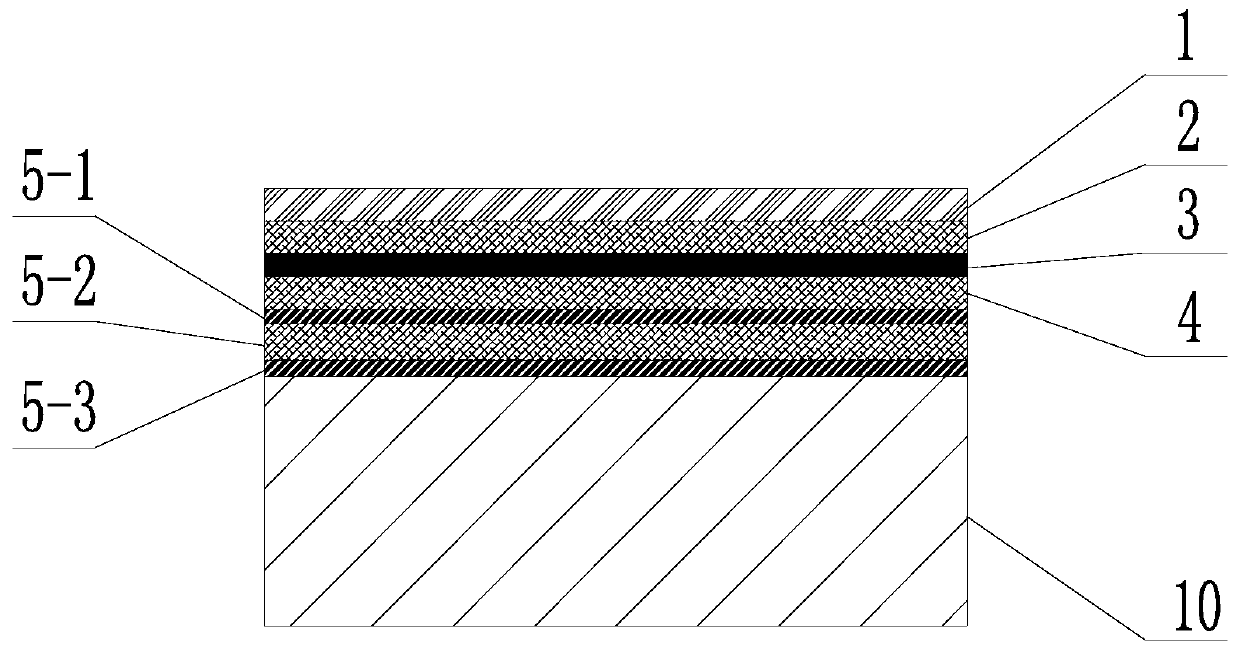

[0033] Specific implementation mode one: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Figure 6 and Figure 7 As shown, this specific embodiment adopts the following technical scheme: the integrated photovoltaic tile includes a front film layer 1, a first adhesive film layer 2, a photovoltaic cell layer, a second adhesive film layer 4, a back film layer 5 and a tile base layer 10 , the front film layer 1, the first adhesive film layer 2, the photovoltaic cell layer, the second adhesive film layer 4, the back film layer 5 and the tile base layer 10 are integrally formed.

[0034] Further, the front film layer 1, the first adhesive film layer 2, the photovoltaic cell layer, the second adhesive film layer 4 and the back film layer 5 integrally form a photovoltaic tile body, and the photovoltaic tile body and the tile base layer 10 are connected in two ways: One connection method is that the photovoltaic tile body is integrally formed on the tile base layer 1...

specific Embodiment approach 2

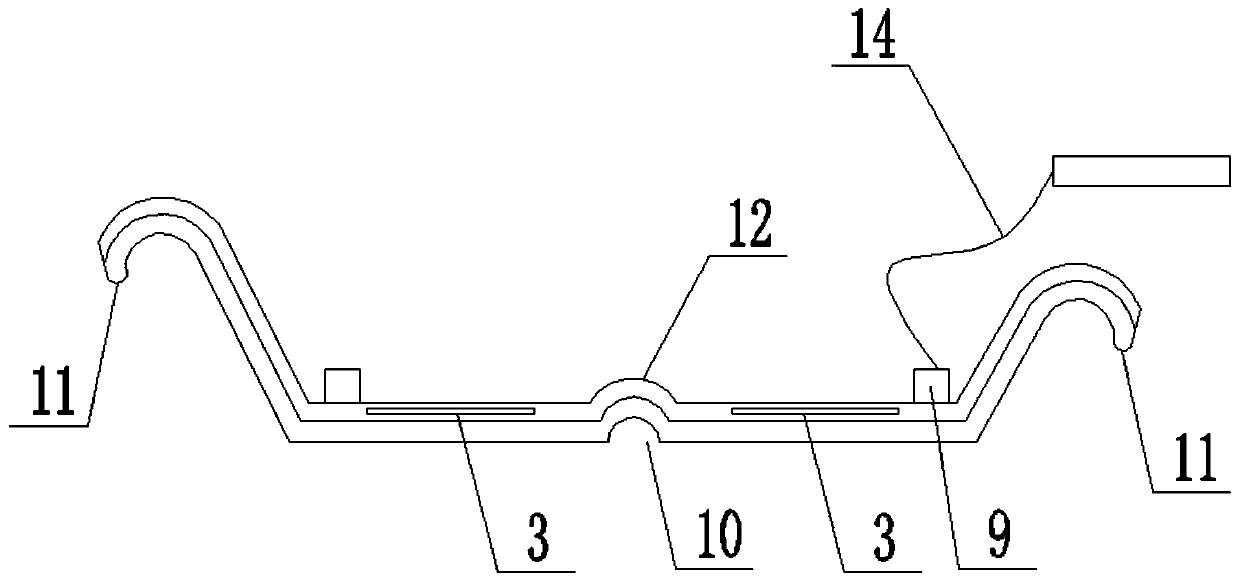

[0043]Embodiment 2: This embodiment is a further limitation of Embodiment 1. The integrated photovoltaic tile includes a front film layer 1, a first adhesive film layer 2, a photovoltaic cell layer, a second adhesive film layer 4 and a back film layer. 5. The front film layer 1, the first adhesive film layer 2, the photovoltaic cell layer, the second adhesive film layer 4 and the back film layer 5 integrally form the photovoltaic tile body. At this time, the photovoltaic tile body is flexible and can be bent, and The bending angle range is large. When the initial state of the photovoltaic tile body is horizontal, the bending angle of one end of the photovoltaic tile body is the angle between the plane where the end is located and the plane where the initial state is located, which is similar to the bending angle of one side of the photovoltaic tile body. The angle is the angle between the plane where the side is located and the plane where the initial state is located. When the...

specific Embodiment approach 3

[0044] Specific embodiment three: this embodiment is a further limitation of specific embodiment one or two, the front film layer 1, the first adhesive film layer 2, the photovoltaic cell layer, the second adhesive film layer 4 and the back film layer 5 are integrally formed The photovoltaic tile body, the photovoltaic tile body is integrally formed on the formed tile base layer 10 or integrally formed after being pressed with the tile base layer 10 . There are two ways to connect the photovoltaic tile body and the tile base layer 10. The specific processing process is to place the front film layer 1, the battery layer, the back film layer 5 and the preformed tile base layer 10 or the non-preformed tile base layer 10 in sequence to form The preformed laminated front part, or the non-preformed laminated front part, is laminated and packaged to form one piece.

[0045] Specifically, placing or transporting the non-preformed lamination front part to the working area of the lami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com