Flax spinning device and method

A roving and No. 1 technology, applied in textiles and papermaking, etc., can solve the problems of high cost of spinning device, quality of twisted yarn, high production cost, etc., and achieve high production efficiency, uniform and straight yarn, and improved performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and through the examples. The following examples are to explain the present invention and the present invention is not limited to the following examples.

[0016] Example.

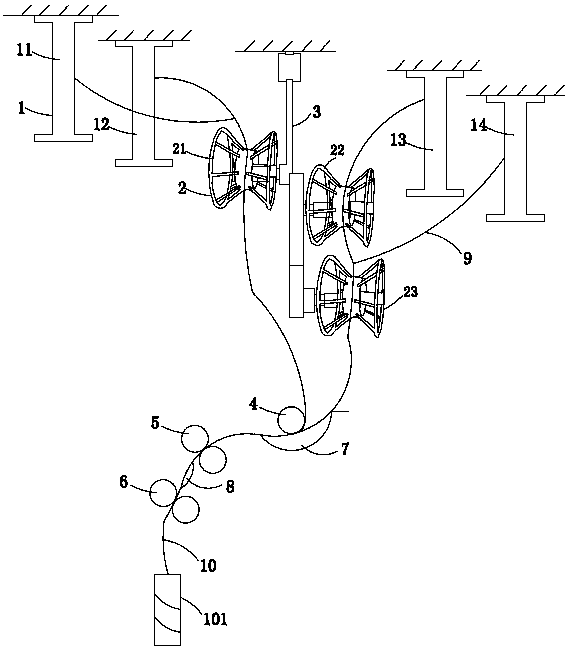

[0017] see figure 1 , the hemp spinning device in this embodiment mainly includes a roving bobbin 1, a yarn guide wheel 2, a yarn guide wheel mechanism 3, a grooved roller 4, a feeding roller 5 and a drafting roller 6, and the yarn guide wheel 2 is installed on the yarn guide wheel mechanism 3 , the roving bobbin 1 is arranged on the side of the guide wheel mechanism 3 .

[0018] The roving bobbin 1 in this embodiment includes a No. 1 roving bobbin 11, a No. 2 roving bobbin 12, a No. 3 roving bobbin 13 and a No. 4 roving bobbin 14, and the yarn guide wheel 2 includes a first yarn guide wheel 21 and a second yarn guide wheel 22 With the third guide wheel 23, the rovings of the No. 1 roving ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com