Special drilling machine for automobile sunshade curtain handrail

A technology of sunshade and special machine, which is applied in boring/drilling, drilling/drilling equipment, reaming device, etc., can solve the problems such as unsuitable drilling processing requirements for automobile sunshade handrails, not found, etc. The overall structure is simple and reasonable, the operation efficiency is high, and the work efficiency is improved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

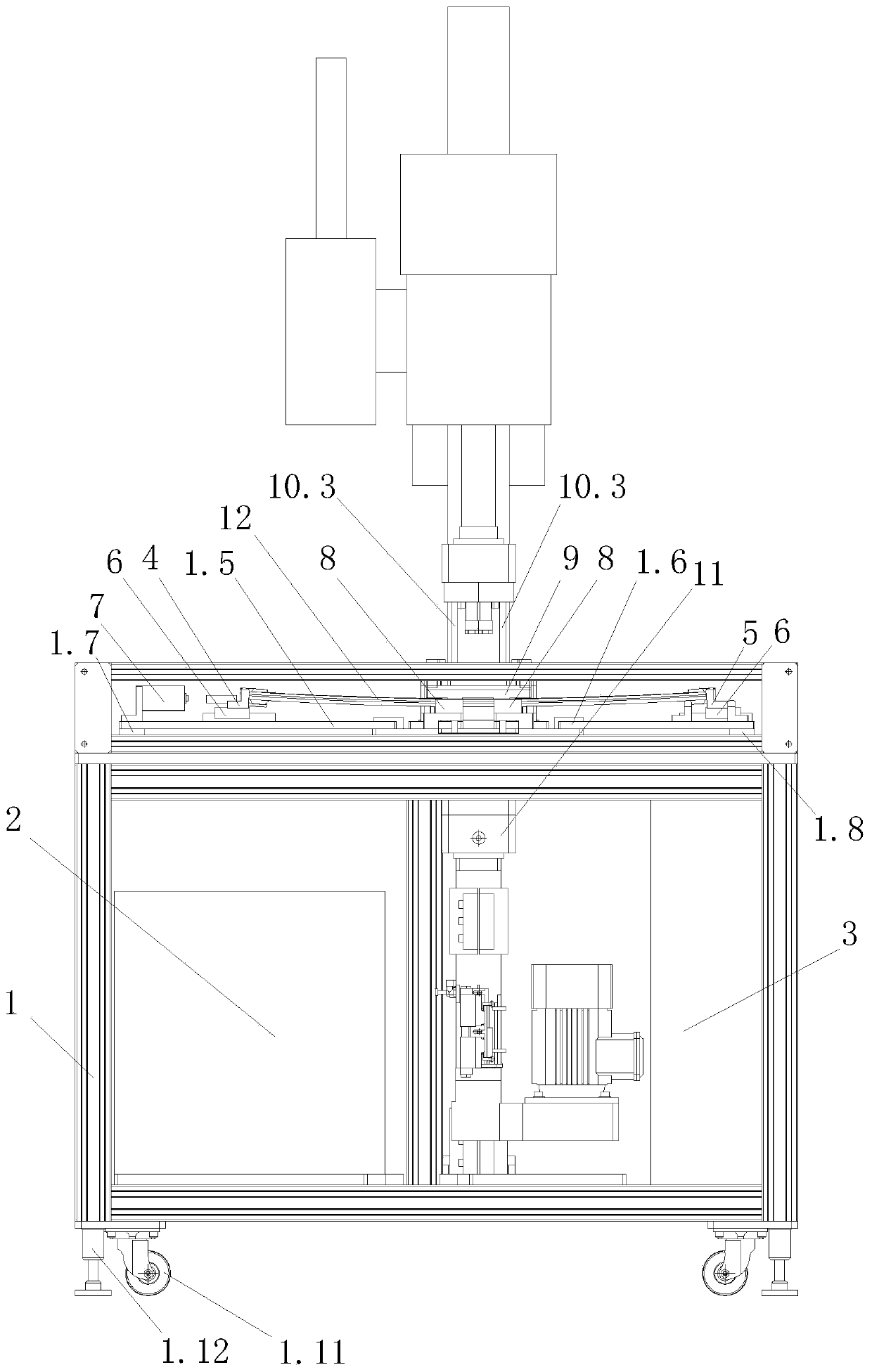

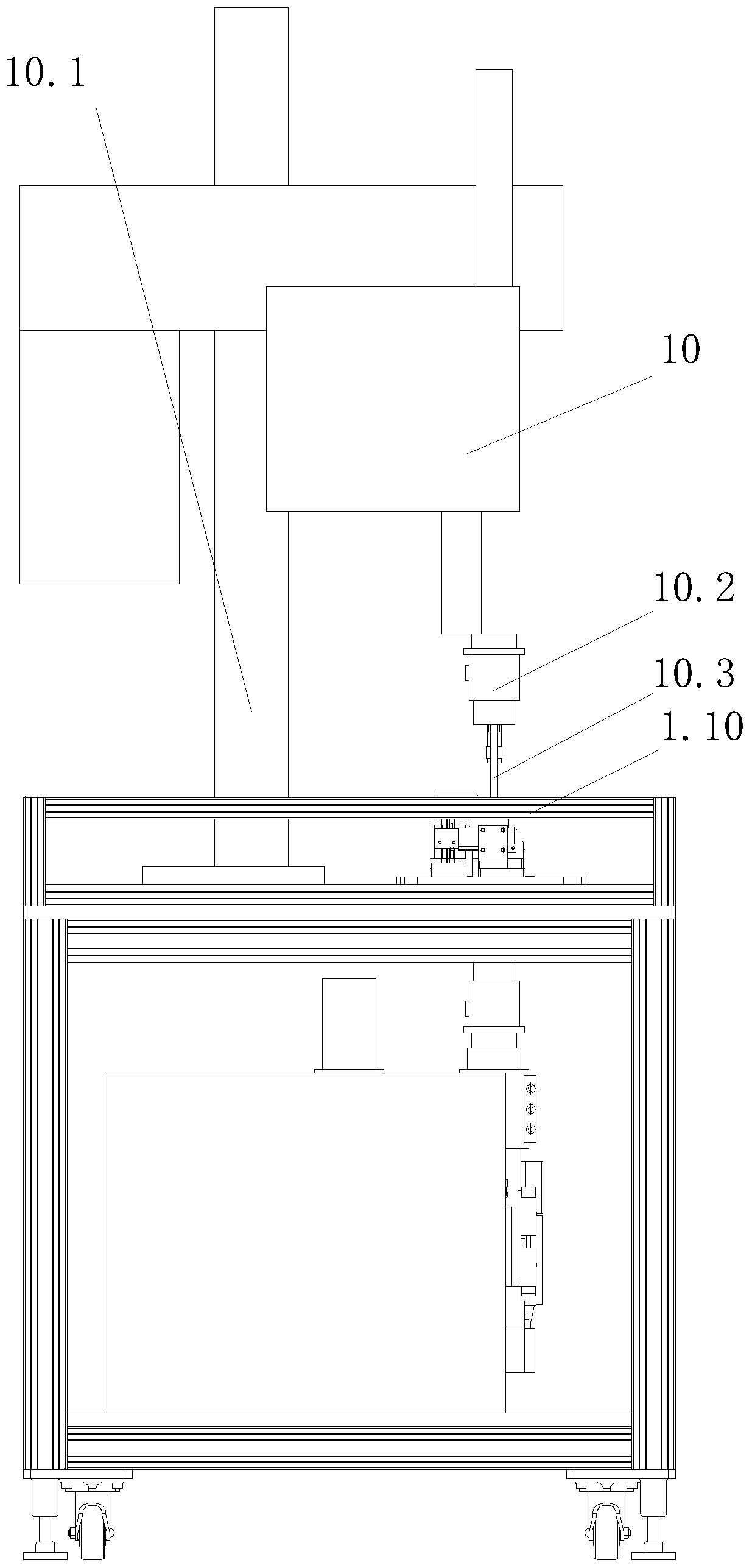

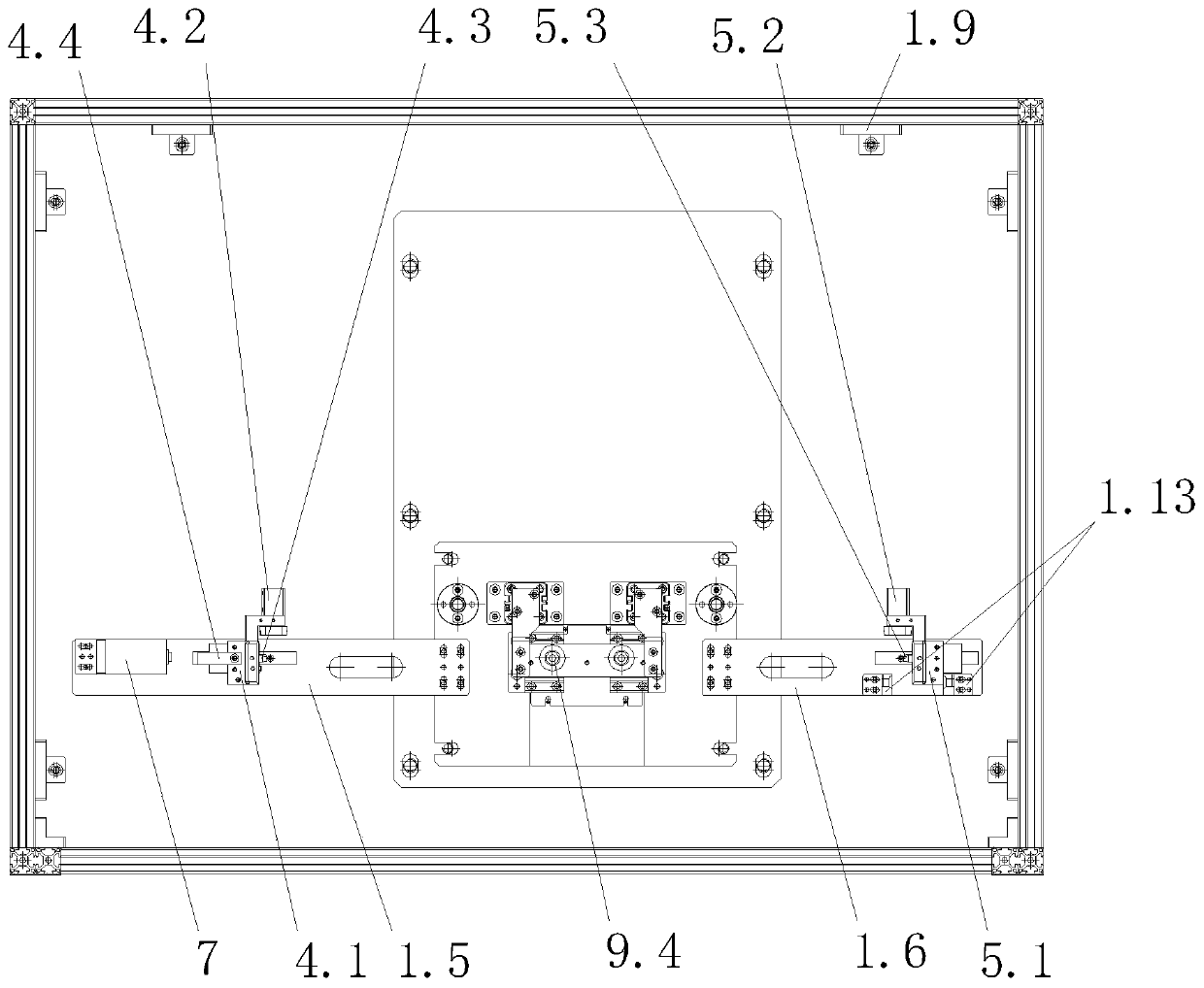

[0023] like Figure 1-Figure 4As shown, the present invention includes a frame 1, a hydraulic station 2, an electrical cabinet 3, a left jig assembly 4, a right jig assembly 5, a slide rail pair 6, a cylinder 7, a support assembly 8, a pressing assembly 9, and a hydraulic drilling machine 10. Deburring assembly 11. The frame 1 is provided with an upper plate and a lower plate. The upper end of frame 1 is provided with not shown in the figure and is used to prevent the automobile sunshade handrail placing plate of automobile sunshade handrail, and described automobile sunshade handrail placing plate is fixed on the fixing seat that is fixed together with the upper end of frame 1 1.9 on. The upper end of the frame 1 is also provided with a guardrail 1.10. The upper plate includes an upper plate body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com