Aluminum alloy rock wool galvanized edge laminboard

A technology of aluminum alloy and rock wool, which is applied in the field of building plate structure, can solve the problems of unsightly appearance, single structure, increased manual work, etc., and achieve the effect of not easily deformed and damaged, strengthened strength and strength, and saved labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

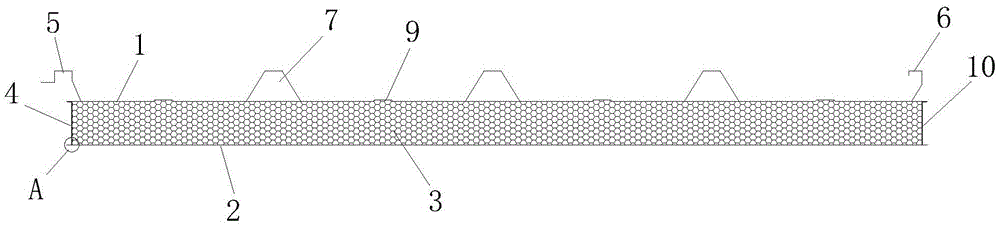

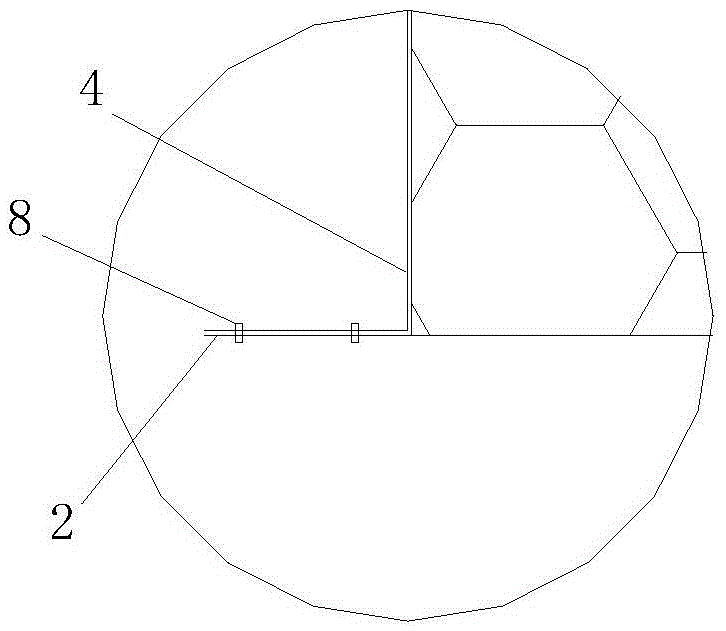

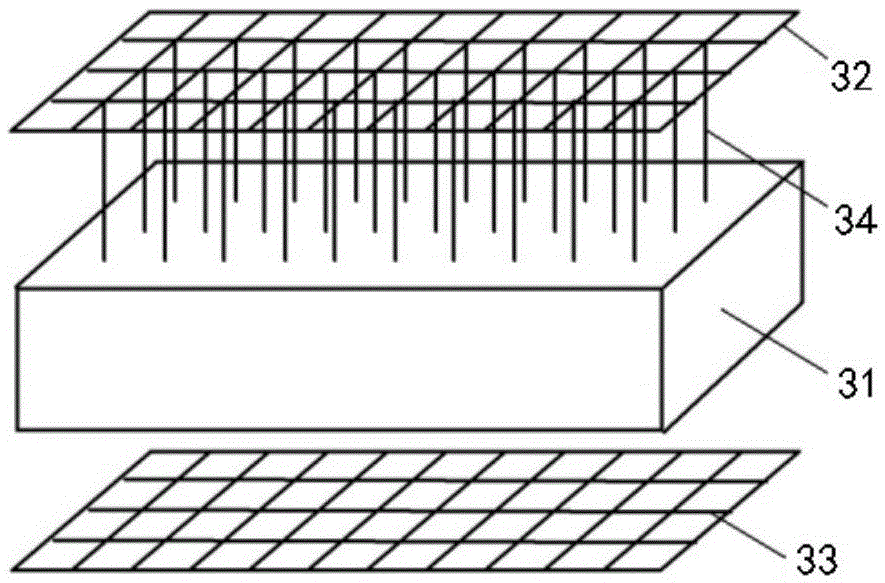

[0013] refer to Figure 1 to Figure 3 As shown, the present invention comprises an upper plate 1 and a lower plate 2 made of aluminum alloy, and a rock wool sandwich panel 3 is arranged between the upper plate 1 and the lower plate 2, and the rock wool sandwich plate 3 includes a rock wool layer 31, which is respectively arranged on The upper and lower mesh structure layers 32 / 33 on the upper and lower surfaces of the rock wool layer 31 and the connecting piece 34, the connecting piece 34 penetrates the rock wool layer 31 and connects the upper and lower mesh structure layers, and the upper and lower mesh structure layers All are steel wire mesh, and the connec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com