Paper transmitting device suitable for splitting machine

A technology of transmission device and slitting machine, which is applied in the direction of transportation and packaging, winding strips, sending objects, etc., which can solve the problems of damaged boards, difficult separation, labor consumption, etc., and achieve the effect of enhancing static electricity and not being easily damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

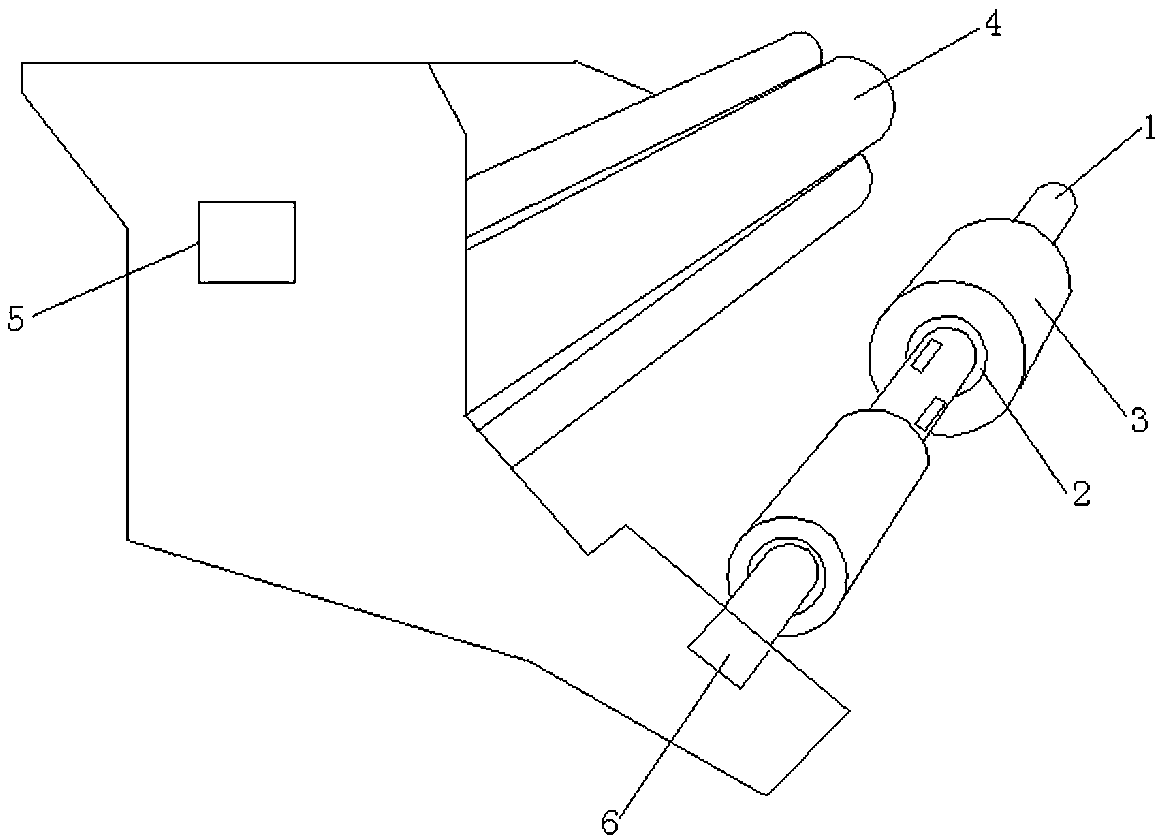

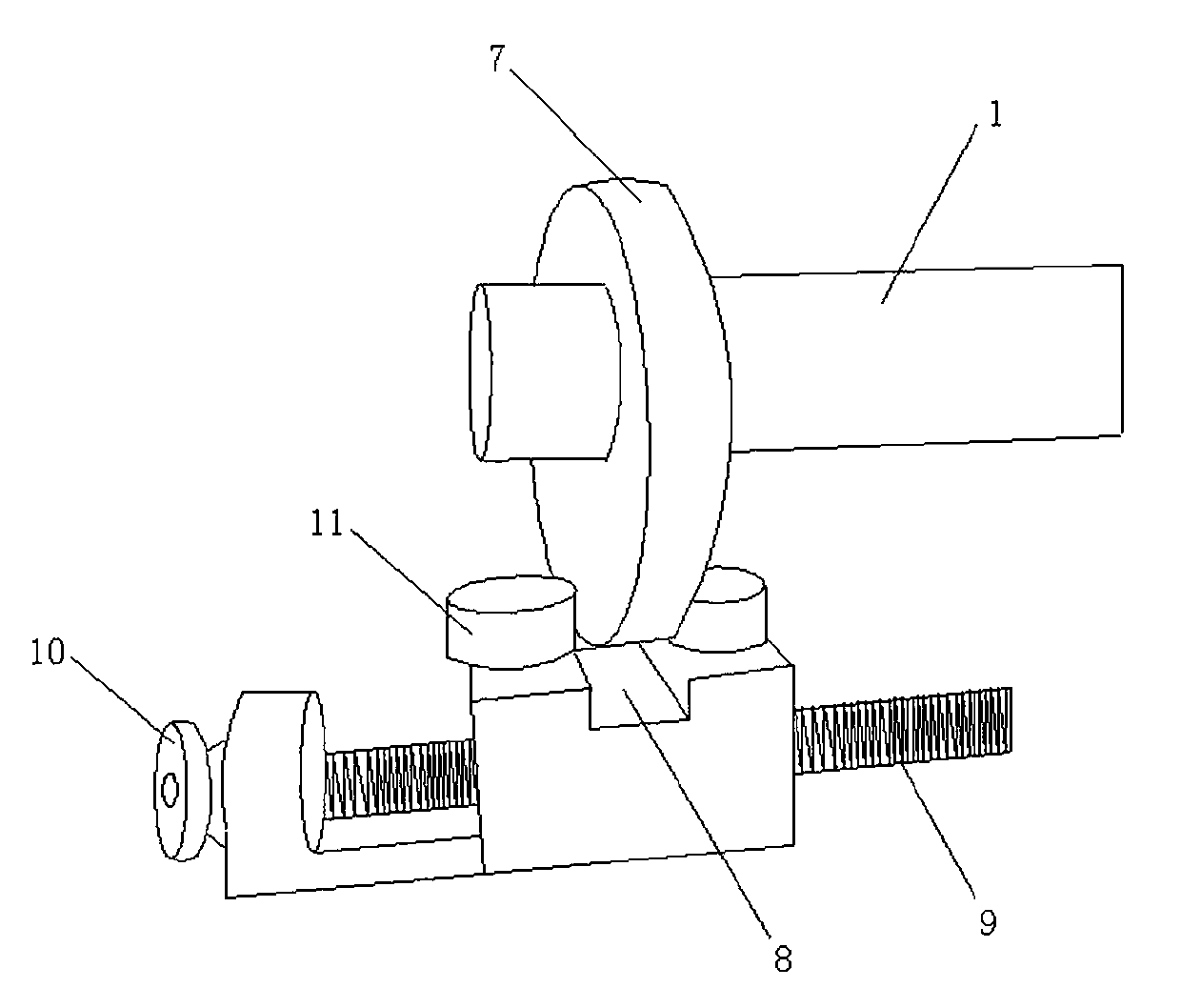

[0011] In order to further reveal the technical solutions of the present invention, the following describes the implementation of the present invention in detail in conjunction with the accompanying drawings: figure 1 As shown, a paper conveying device suitable for a slitter includes a reel 1 arranged on the slitter and a paper cylinder 2 sleeved on the reel 1, and paper 3 is wound on the surface of the paper cylinder 2. One side of the reel 1 is provided with a transmission device 4 for conveying the paper 3 and the board, and the side of the transmission device 4 is provided with an electrostatic generator 5, which can enhance the static electricity around the transmission device 4, so that the paper 3 and the board are always combined during the transmission process Together, the board is effectively protected and the board is not easily damaged. One end of the reel 1 is provided with a fine-tuning device 6 for adjusting the position of the paper tube 2, so that the paper t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com