Tire mounting and dismounting head and tire mounting and dismounting machine

A tire changer and tire disassembly technology, applied in tire installation, tire parts, transportation and packaging, etc., can solve the problems of damage to the tire mouth rubber, complex structure of the tire disassembly head, etc. Wide range of use, small volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

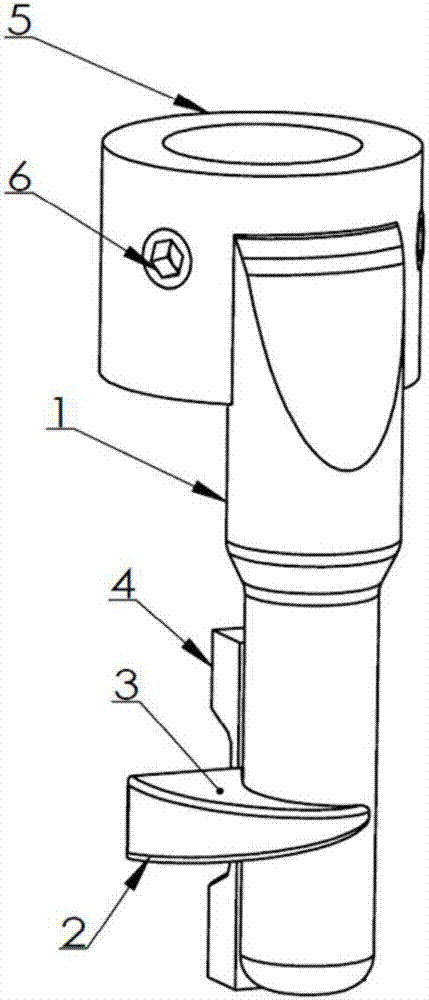

[0029] see figure 1 , the figure shows a schematic structural view of the tire dismounting head of this embodiment, including: a fixed part 5, a working part (not shown) connected to the fixed part 5, a connecting part arranged on the fixed part 5 part and the positioning part set on the working part.

[0030] Wherein, the fixed part 5 includes a mounting hole matched with the hexagonal shaft of the tire changer, the mounting hole can be a round through hole, and the hexagonal shaft can be placed in the mounting hole, and the fixed part 5 is fixedly connected with the tire changer through the connecting part 6 For example, the connecting part 6 is a screw hole, which can be arranged on the side wall of the fixing part 5. The number of connecting parts 6 can be selected according to the needs. On the tire changer.

[0031] In this embodiment, one end of the working part is connected to the side wall of the fixed part 5. For example, the working part can be welded on the fixed...

no. 2 example

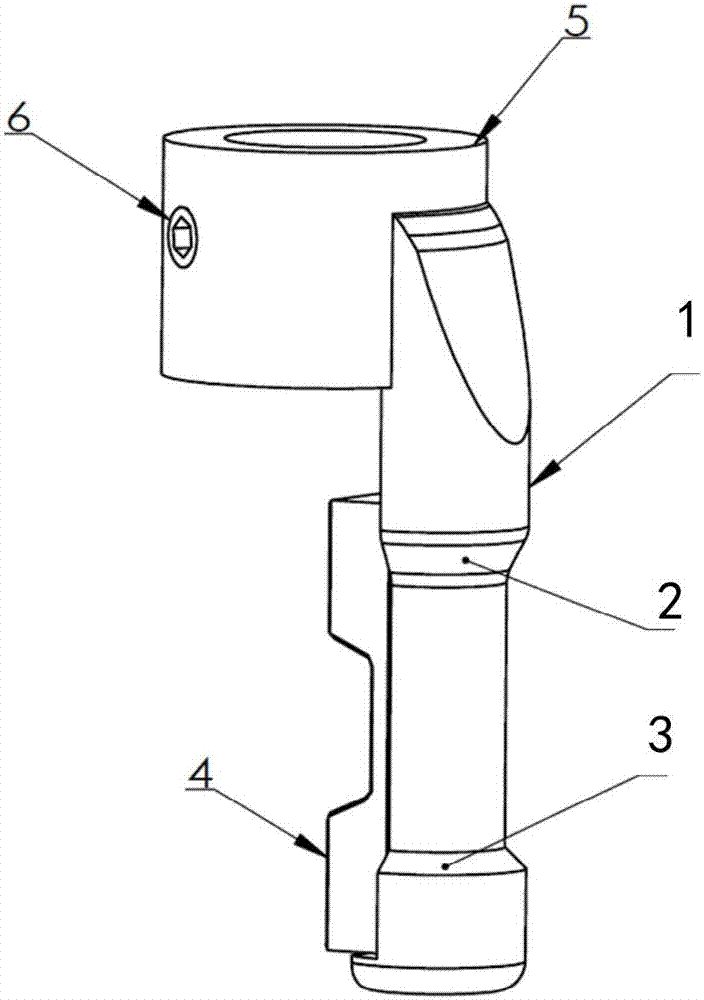

[0038] see figure 2 , the figure shows another schematic view of the structure of the tire dismounting head of this embodiment, including: a fixed part 5, a working part connected with the fixed part 5, a connecting part arranged on the fixed part 5 and a working part arranged on the working part on the positioning section.

[0039] Wherein, the fixed part 5 includes a mounting hole matched with the hexagonal shaft of the tire changer, the mounting hole can be a round through hole, and the hexagonal shaft can be placed in the mounting hole, and the fixed part 5 is fixedly connected with the tire changer through the connecting part 6 For example, the connecting part 6 is a screw hole, which can be arranged on the side wall of the fixing part 5. The number of connecting parts 6 can be selected according to the needs. On the tire changer.

[0040] In this embodiment, one end of the working part is connected to the side wall of the fixed part 5. For example, the working part ca...

no. 3 example

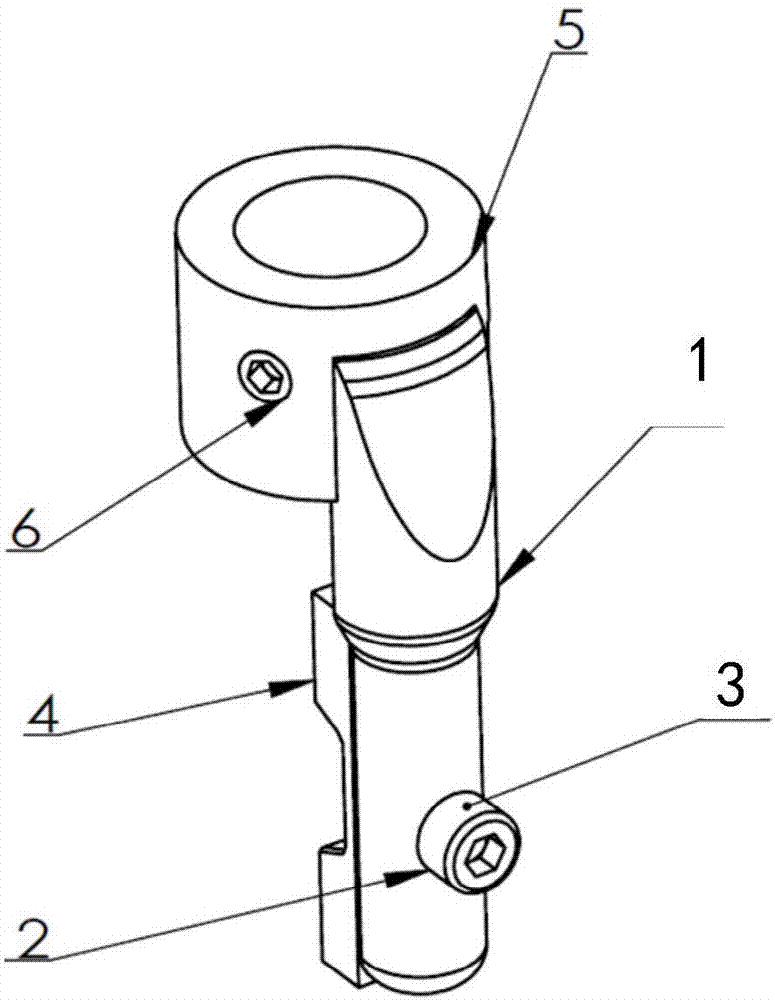

[0048] see image 3 , the figure shows another schematic view of the structure of the tire dismounting head of this embodiment, including: a fixed part 5, a working part connected with the fixed part 5, a connecting part arranged on the fixed part 5 and a working part arranged on the working part on the positioning section.

[0049] Wherein, the fixed part 5 includes a mounting hole matched with the hexagonal shaft of the tire changer, the mounting hole can be a round through hole, and the hexagonal shaft can be placed in the mounting hole, and the fixed part 5 is fixedly connected with the tire changer through the connecting part 6 For example, the connecting part 6 is a screw hole, which can be arranged on the side wall of the fixing part 5. The number of connecting parts 6 can be selected according to the needs. On the tire changer.

[0050] In this embodiment, one end of the working part is connected to the side wall of the fixed part 5. For example, the working part can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com