Automobile hub automatically-adjusted targeted polishing mechanism

A technology of automatic adjustment and grinding mechanism, applied in the direction of grinding machine parts, grinding machines, grinding workpiece supports, etc., can solve the problems of easily scratching the wheel hub, trouble, etc., and achieve the effect of not easy damage and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

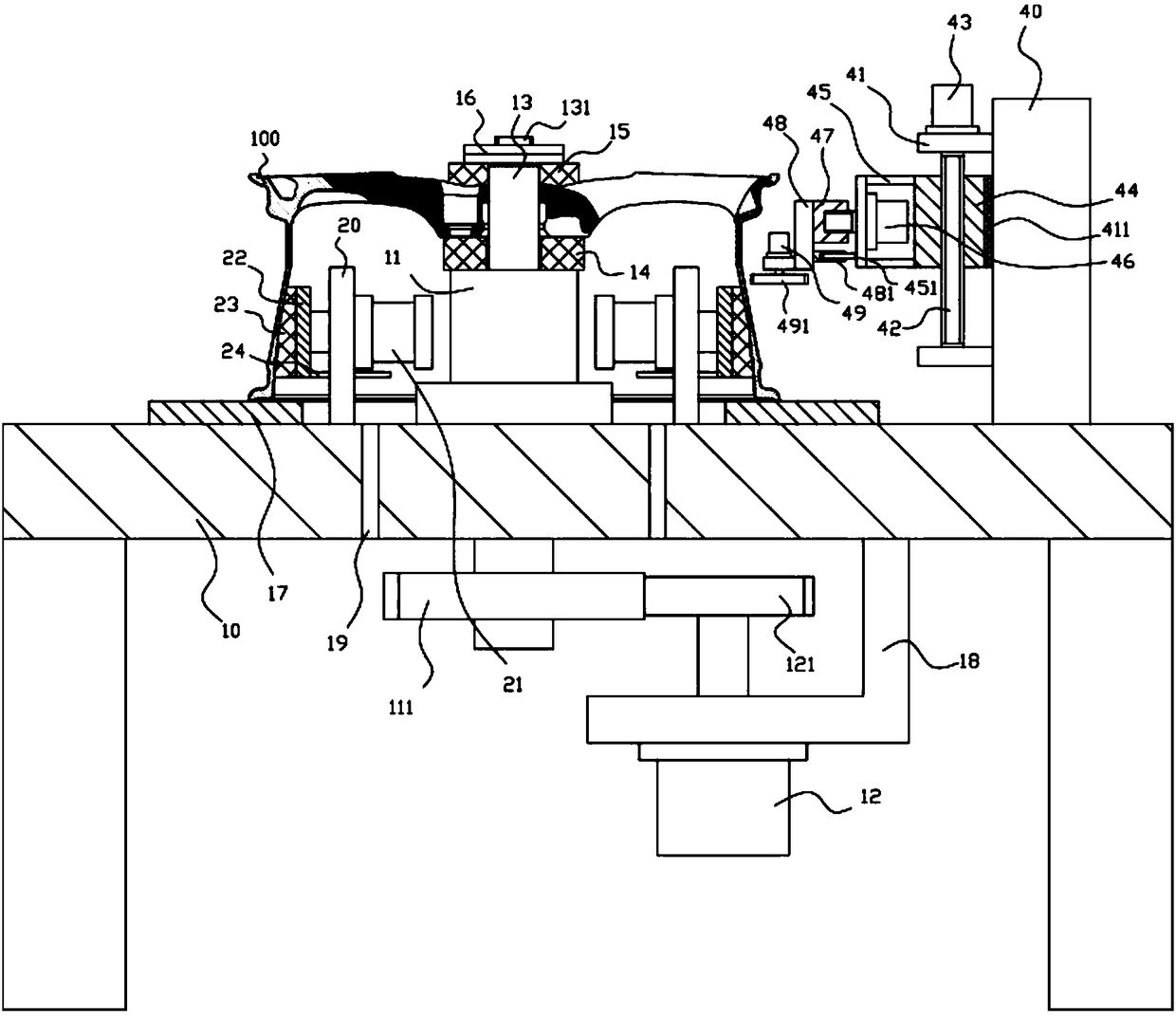

[0017] Example: see figure 1 As shown, a kind of automobile wheel hub automatic adjustment fixed-point grinding mechanism comprises a frame 10, the top surface of the middle part of the top plate of the frame 10 is hinged with a rotating main shaft 11, and the bottom end of the rotating main shaft 11 extends out of the middle part of the top plate of the frame 10 The bottom surface is also fixed with transmission gear 111, the bottom surface of the top plate of frame 10 is fixed with lower support frame 18, is fixed with rotary servomotor 12 on the lower support frame 18, is fixed with drive gear 121 on the output shaft of rotary servomotor 12, drive gear 121 is meshed with the transmission gear 111, the middle part of the top surface of the rotating main shaft 11 has a positioning column 13, the lower elastic clamping block 14 is inserted in the positioning column 13, and the positioning column 13 is inserted in the central through hole of the hub 100, positioning The top of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com