Pressure-resistant anti-shedding rubber roller

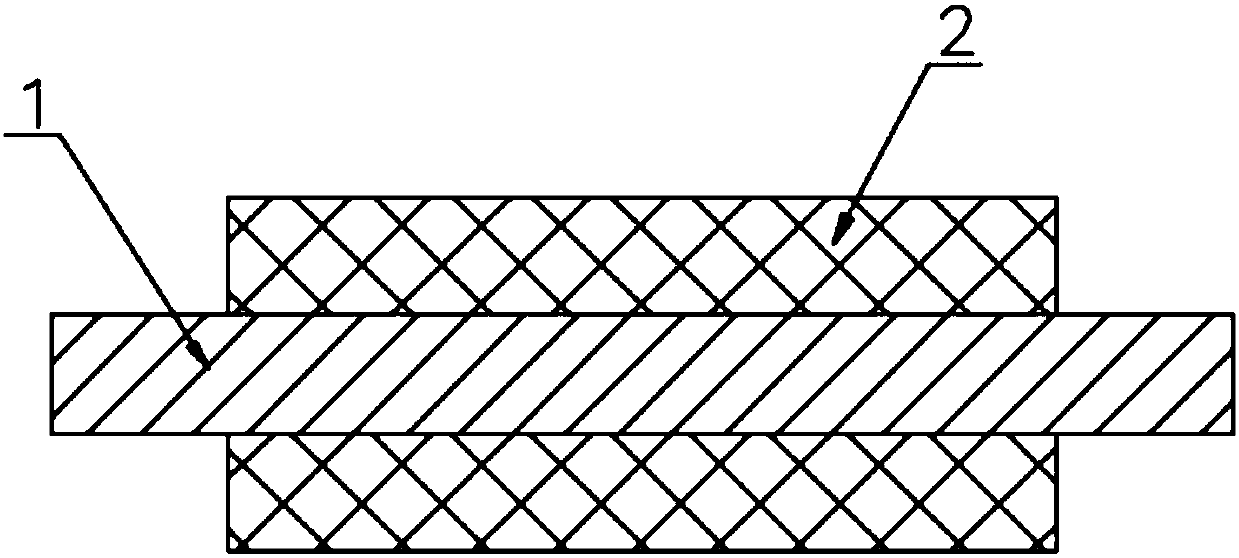

A rubber roller and anti-shedding technology, applied in the field of rubber rollers, can solve problems such as affecting the printing quality and printing effect, the separation of the rubber layer 2 from the roller core 1, and the damage and scrapping of the rubber layer 2, so as to achieve not easy damage and good resistance. , the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

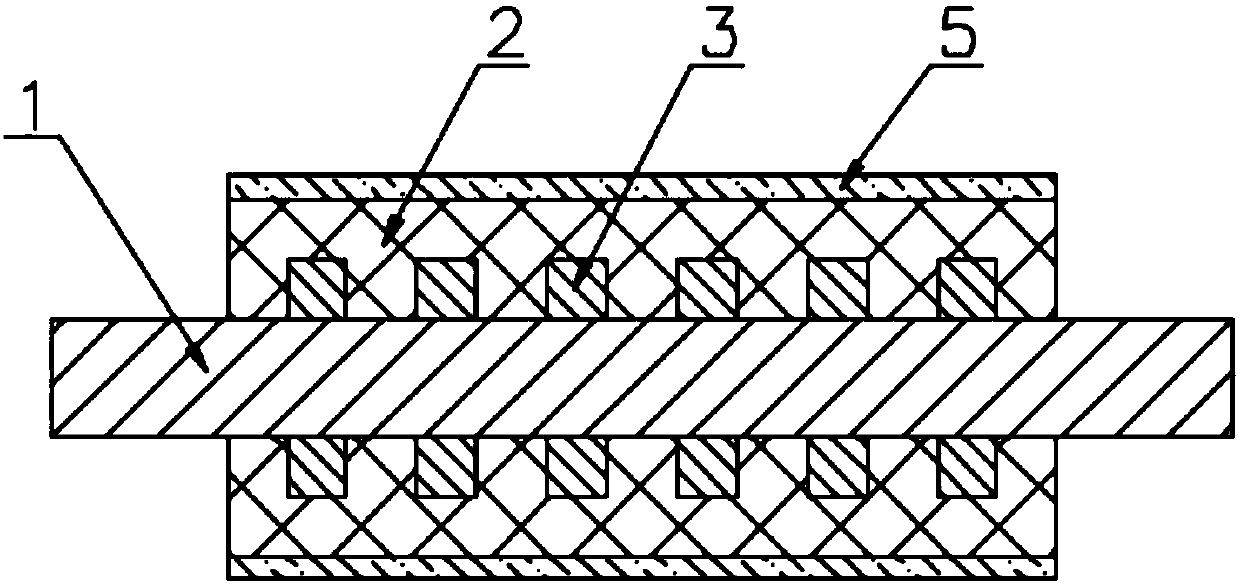

[0026] Embodiment 1: A kind of pressure-resistant and anti-shedding rubber roller, such as figure 2 As shown, it includes a roll core 1, a rubber layer 2 and a compression block 3, the rubber layer 2 is fixedly installed on the outer surface of the roll core 1, the thickness of the rubber layer 2 is 5mm, and the compression block 3 is arranged on the roll core 1 Between the rubber layer 2, the anti-compression block 3 is an integral ring, and six integral annular anti-compression blocks 3 are fixedly installed on the outer surface of the roller core 1 at equal intervals in the transverse direction, and the longitudinal direction of the anti-compression block 3 The cross-sectional shape is rectangular, the rubber layer 2 is chlorosulfonated polyethylene rubber, and the rubber layer 2 is wrapped with a polyurethane rubber layer 5, and the thickness of the polyurethane rubber layer 5 is 0.2 mm.

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is that four anti-pressure blocks 3 are arranged at equal intervals in the circumferential direction of the roller core 1 .

Embodiment 3

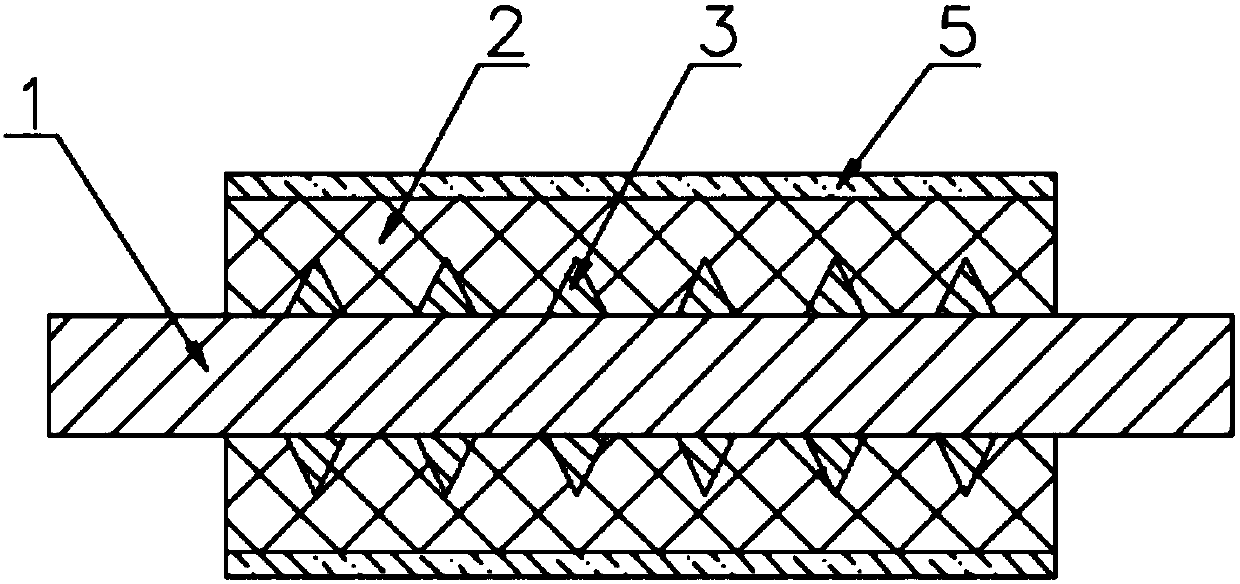

[0028] Embodiment 3: The difference with Embodiment 1 is that, as image 3 As shown, the longitudinal cross-sectional shape of the compression block 3 is triangular.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com