Fixing mechanism for automobile hub

A fixing mechanism, a technology for automobile wheel hubs, applied in workpiece clamping devices, manufacturing tools, etc., can solve the problems of unfixed wheel hubs, troublesome deburring, easy scratching of wheel hubs, etc., achieving not easy damage, good effect, and convenient maintenance. The effect of maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

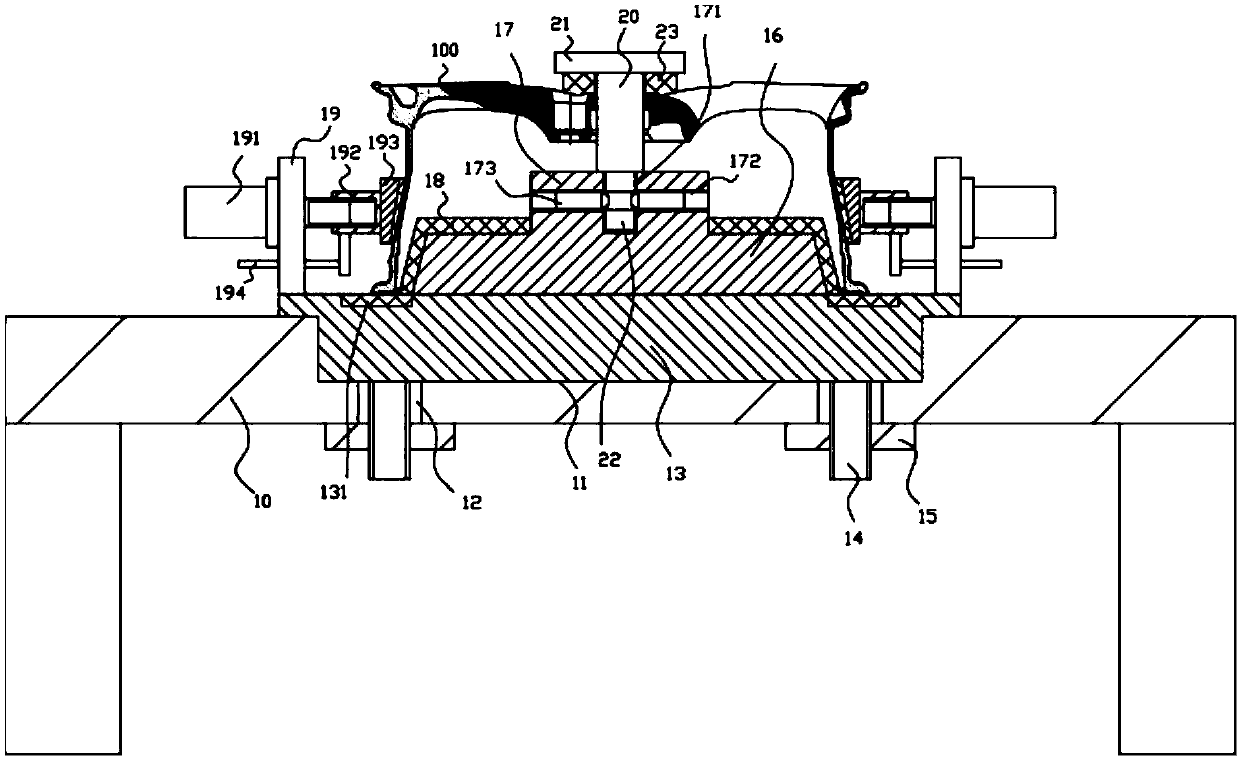

[0013] Example: see figure 1 As shown, a kind of automobile hub fixing mechanism comprises frame 10, and the middle part of the top plate of described frame 10 has installation groove 11, and the bottom surface of installation groove 11 has a plurality of positioning through holes 12, and bottom block 13 is inserted in In the mounting groove 11, a plurality of positioning screws 14 on the bottom surface of the bottom block 13 pass through the corresponding positioning through holes 12, and the bottom end of the positioning screws 14 stretches out from the top plate of the frame 10 and is screwed with a positioning nut 15, the positioning nut 15 is pressed against the bottom surface of the top plate of the frame 10, the bottom surface of the bottom block 13 is pressed against the bottom surface of the installation groove 11, and the middle part of the top surface of the bottom block 13 is fixed with a main connection block 16, and the top surface of the main connection block 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com